Key switch device for combined key caps

A technology of key switch and combination key, which is applied in the direction of electric switch, emergency protection device, contact operating mechanism, etc. It can solve the problems of low cost of production equipment, low precision of injection molding, stamping precision, lower limit of elastic force, etc., and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

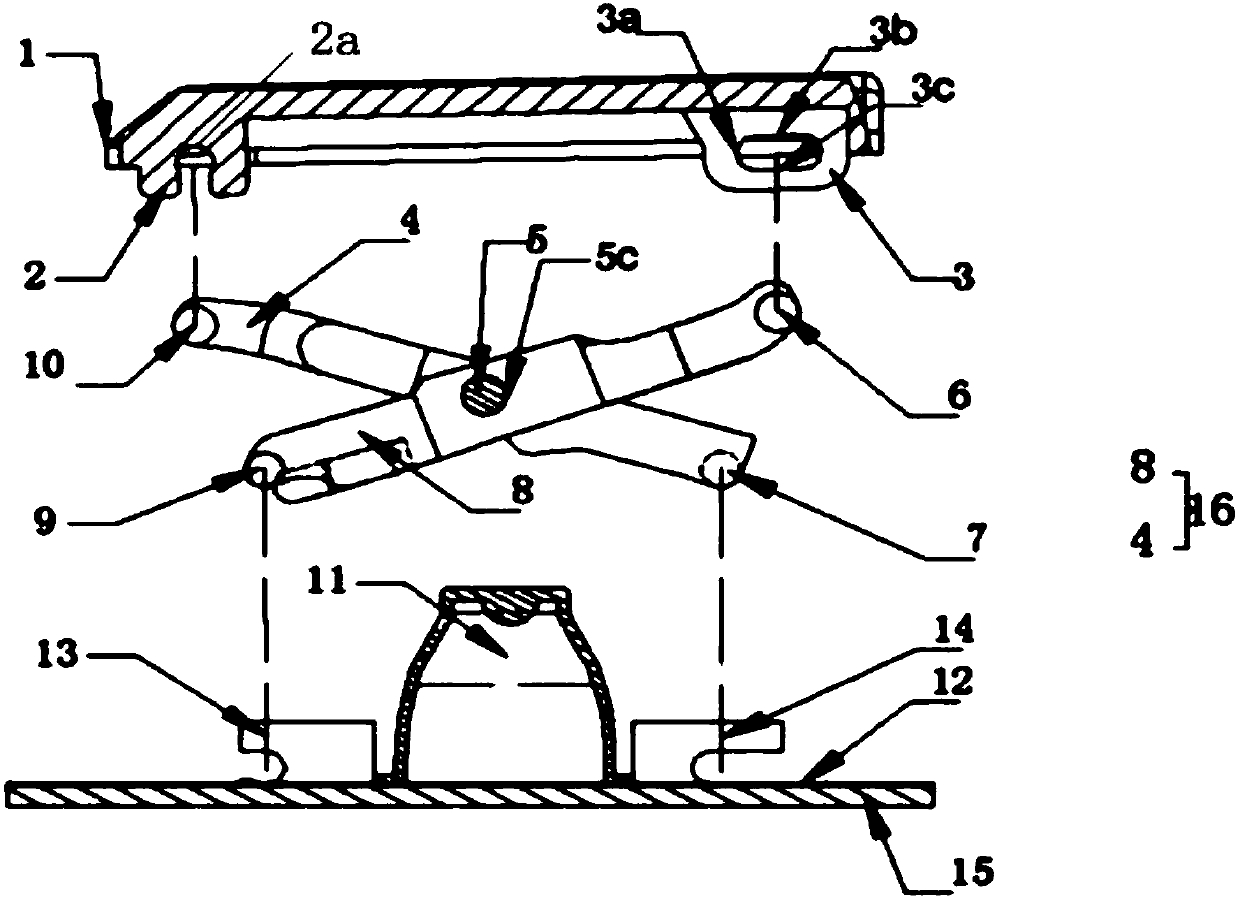

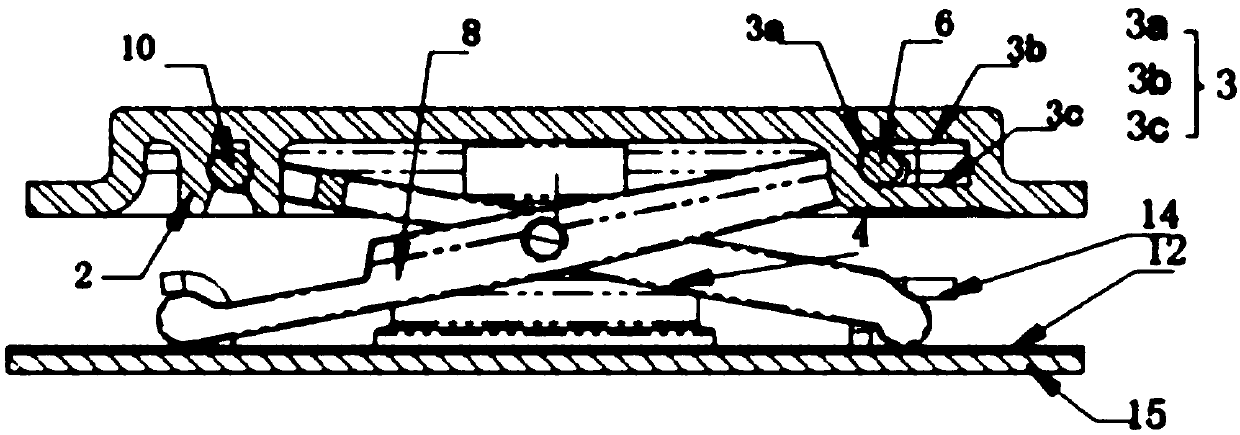

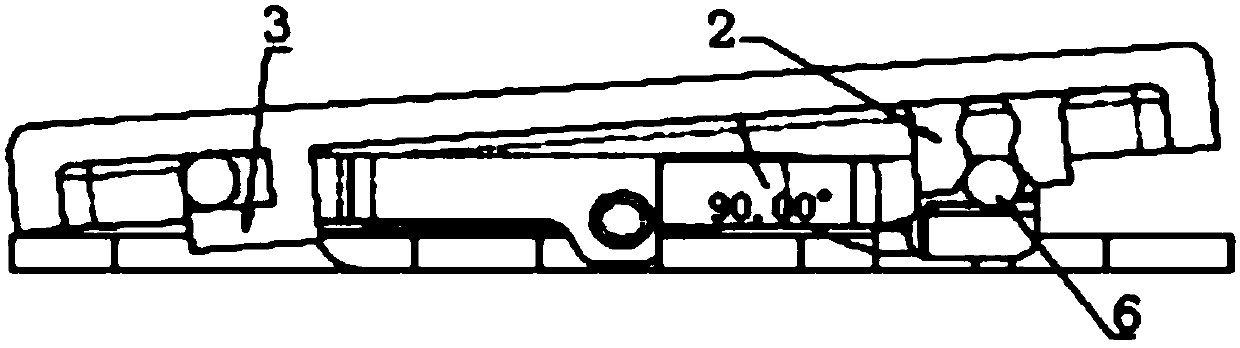

[0105] Embodiment 1, see Figure 17 -- Figure 26 , including a keycap 1 with characters printed on its upper surface, a reset body (consisting of a rubber spring ring 11), a switch circuit (consisting of a membrane switch circuit 12), a support plate 15 with a matching part, and scissor feet with an upper and lower matching part Support 16, the scissor foot support 16 is respectively connected with the keycap 1 and the matching portion of the support plate 15 through the upper and lower matching parts to rotate or slide, and the scissor foot support 16 constitutes a synchronous linkage support structure through the transmission of force between the linkage parts to ensure that the key The cap 1 moves up and down parallel to the support plate. The key cap 1 is composed of the I key assembly 33 and the II key assembly 35. The I key assembly 33 and the II key assembly 35 are fixedly connected, and the I key assembly 33 is located on the II key assembly 35; II The key assembly 3...

Embodiment 2

[0142] Embodiment 2, see Figure 27 , Ⅱ The first bending edge 36 and the second bending edge 37 formed by stamping on the key assembly 35 are bent along the X direction to form the X direction bending part 44; The formed z-direction bending edge 39 and the II bending edge 37 are all along the X direction and point to the middle of the key, and the plate surface is bent near the cantilever end of the II bending edge 37 to form a z-direction bending edge 39, and the key is reversed to match the arc 25 is composed of the upper surface of the bend between the II bending edge 37 and the z-direction bending edge 39, and the undercut fitting part is composed of an arc-shaped key undercut fitting arc 25; in the middle part of the II key assembly 35 Nearby, there is a through hole 35a in the middle of the key II that runs through the board surface; there are key installation guide surfaces 45 formed by chamfering on the outside of the four z-direction bending edges 39; the key underc...

Embodiment 3

[0157] Embodiment 3, see Figure 45 , Ⅱ The mating portion of the key assembly 35 is composed of a first bending portion 49, a second bending portion 50, and a third bending portion 51, wherein the first bending portion 49 and the second bending portion 50 are arranged along the Y direction, and the first bending portion 50 is arranged along the Y direction. The bending part 49 is located between the two second bending parts 50, and the first bending part 49 and the second bending part 50 are provided with a stamped and formed folding arc plate 48 and a guide panel 47; the first bending part 49 of the folded arc plate 48 corresponds to the position of the folded arc plate 48 of the second bending portion 50 and has the same center, and the folded arc plate 48 of the same circle center constitutes the keycap rotating portion 2, and the guide panel of the first bent portion 49 47. The position of the guide panel 47 of the second bending part 50 corresponds to an inverted eight ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com