Pipe material connecting accessories

A technology for connecting accessories and connecting parts, which is applied in the direction of connecting components, rods, mechanical equipment, etc. It can solve the problems of inconvenient installation and affecting the aesthetics of products, so as to prevent corrosion of fasteners, facilitate installation and improve safety. Effects on Sexuality and Lifespan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

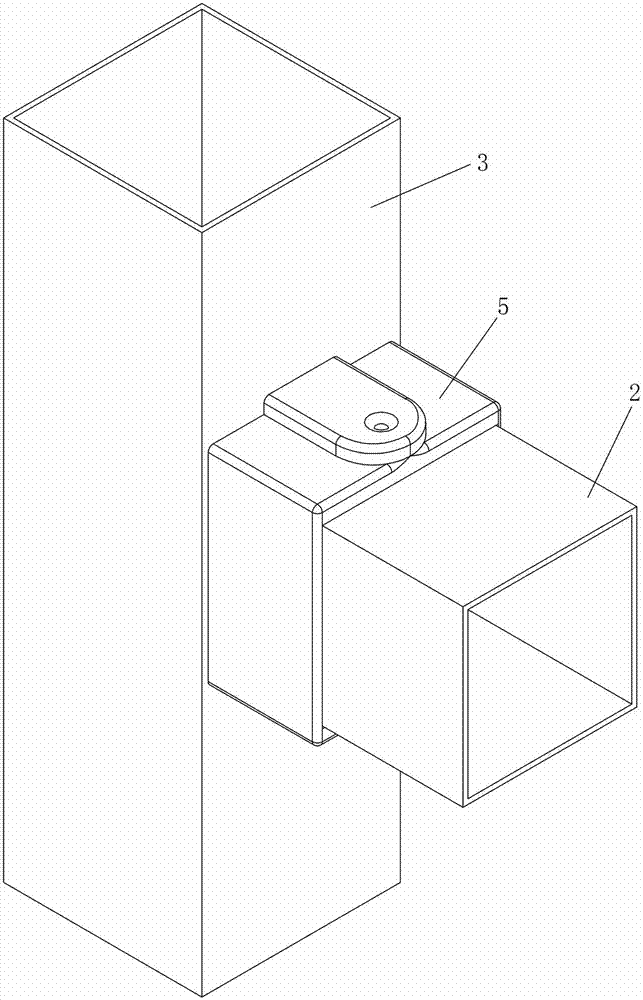

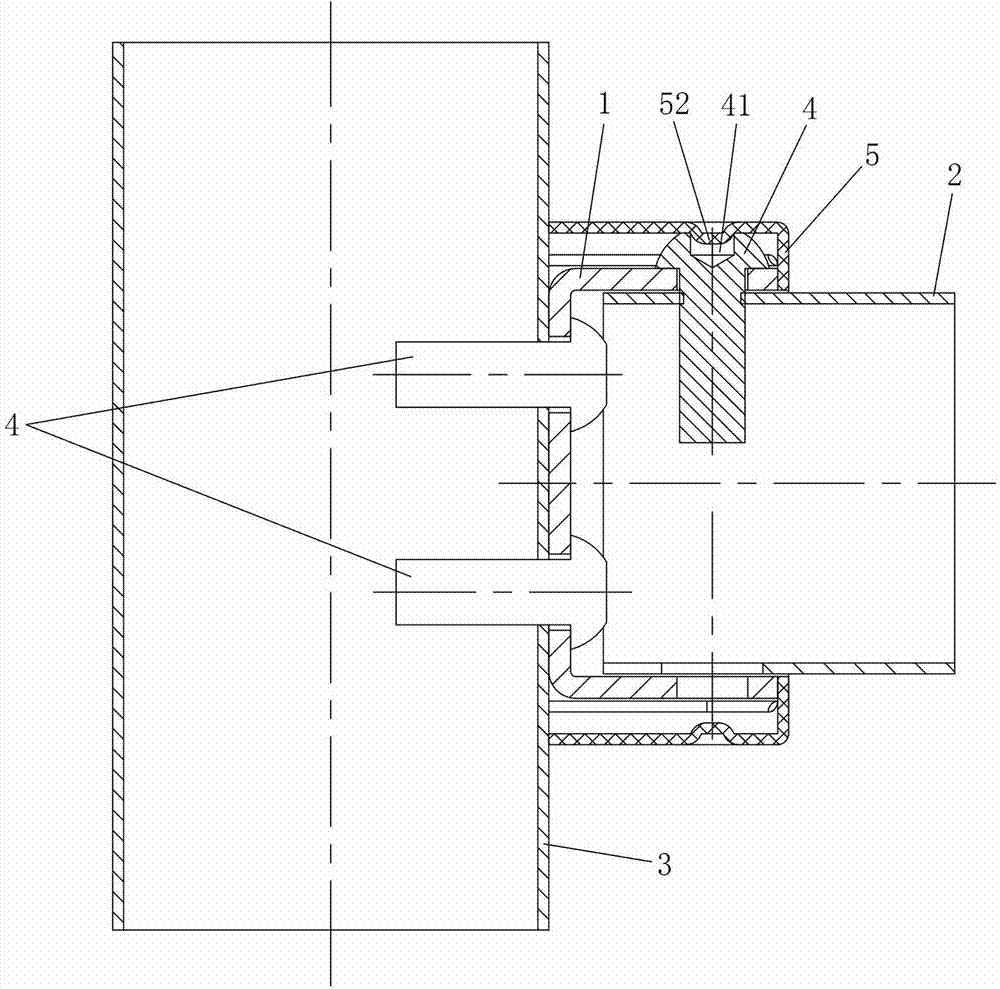

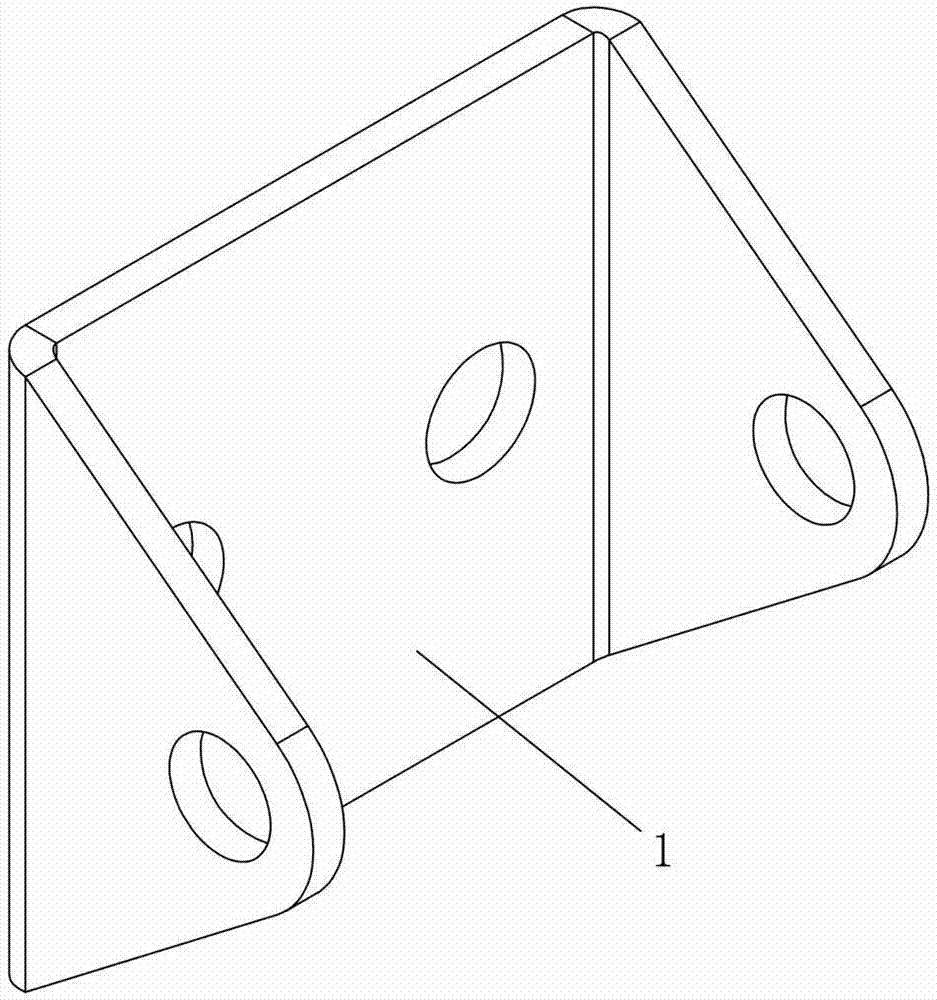

[0032] Such as Figure 1 to Figure 4 As shown, the first embodiment of the pipe connection fitting of the present invention includes a fastener 4 and a connecting piece 1 for connecting the first pipe 2 (horizontal pipe) and the second pipe 3 (column). Part 1 connects the end of the first pipe 2 to the middle of the second pipe 3 through fasteners 4, and also includes a shielding sleeve 5, which is sleeved on the first pipe 2 and can slide along the first pipe 2. The shielding sleeve 5 is clamped with the fastener 4 and covers the connecting piece 1 and the fastener 4. In the pipe connection fitting of the present invention, after the connector 1 connects the end of the first pipe 2 to the middle of the second pipe 3 through the fastener 4, the shielding sleeve 5 is covered on the outside of the connector 1 and the fastener 4 to avoid It prevents the direct exposure of the connecting piece 1 and the fastening piece 4 and affects the aesthetics. At the same time, it can effect...

Embodiment 2

[0038] Such as Figure 5 to Figure 7 As shown, the second embodiment of the pipe connection fittings of the present invention is basically the same as Embodiment 1, the difference is that this embodiment is provided with a bayonet 53 on the shielding sleeve 5, and the bayonet 53 is connected with the fastener The outer side wall of 4 snap fits. Specifically, the fastener 4 adopts a round head screw, and the round head of the round head screw is exposed to the outside of the first pipe material 2 after installation, and an inwardly convex protrusion is formed on the opposite side walls of the U-shaped chute 56 , the two protrusions and the chute 56 form a bayonet 53, and the sliding of the shield sleeve 5 allows the round head of the round head screw to be placed in the chute 56, and finally the round head of the round head screw squeezes into the card Port 53 forms a snap fit.

Embodiment 3

[0040] Such as Figure 8 to Figure 11 As shown, the third embodiment of the pipe connection fittings of the present invention is basically the same as the first embodiment, the difference is that the first embodiment is provided with a protrusion 11 on the connector 1 and a second one on the shielding sleeve 5. Two elastic locking platforms 54 , the second elastic locking platform 54 is engaged with the protrusion 11 , that is, the shielding sleeve 5 in this embodiment is engaged with the connector 1 .

[0041] In this embodiment, the protrusion 11 is formed by bending a part of the bottom edge of the U-shaped connector 1, and the second elastic clamping platform 54 is a barb-shaped convex platform. The second elastic locking platform 54 is just engaged with the protrusion 11 , and the second pipe material 3 and the protrusion 11 work together to form a limit to the shielding sleeve 5 .

[0042] In other embodiments, there may also be snap-fit components between the shieldi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com