Slide fastener and manufacturing method of slide fastener

A technology of zipper and chain teeth, which is applied in the field of zipper to achieve the effect of improving softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

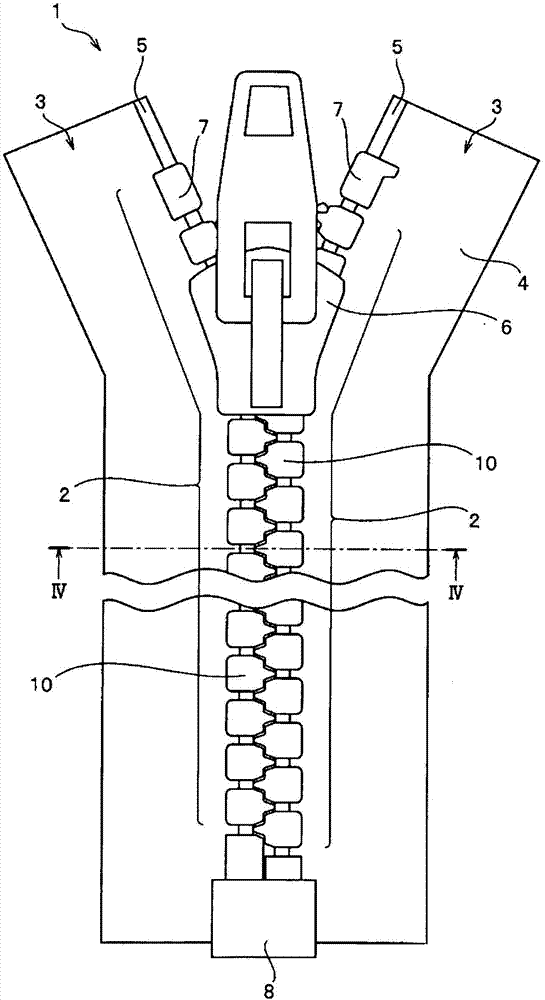

[0064] like figure 1 As shown, the slide fastener 1 related to the invention of the present application is provided with a pair of left and right fastener tapes 3, fastener elements 10 arranged at equal intervals along the side edges of each fastener tape 3, and a fastener element row 2 composed of a plurality of fastener elements 10. The structure of the slider 6 that engages or separates the pair of element rows 2 by sliding, the upper stopper 7 that restricts the sliding of the slider 6 to the upper end side, and the lower stopper 8 that restricts the sliding of the slider 6 to the lower end side .

[0065] In the illustrated example, the structure in which the lower ends of the pair of left and right zipper tapes 3 are connected and fixed by the lower stopper 8 is shown. Separate the structure of the embed. In addition, as the slide fastener 1, the structure of the single-opening slide fastener which used the separate insert on only one side of the both ends of the elem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com