Process for soldering sealing chemiluminescent tube end

A chemiluminescence, tube end technology, applied in the direction of light source, fluorescence, lighting devices, etc., can solve the problems of poor and inability to weld the open end of the chemiluminescence tube and seal the welding effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

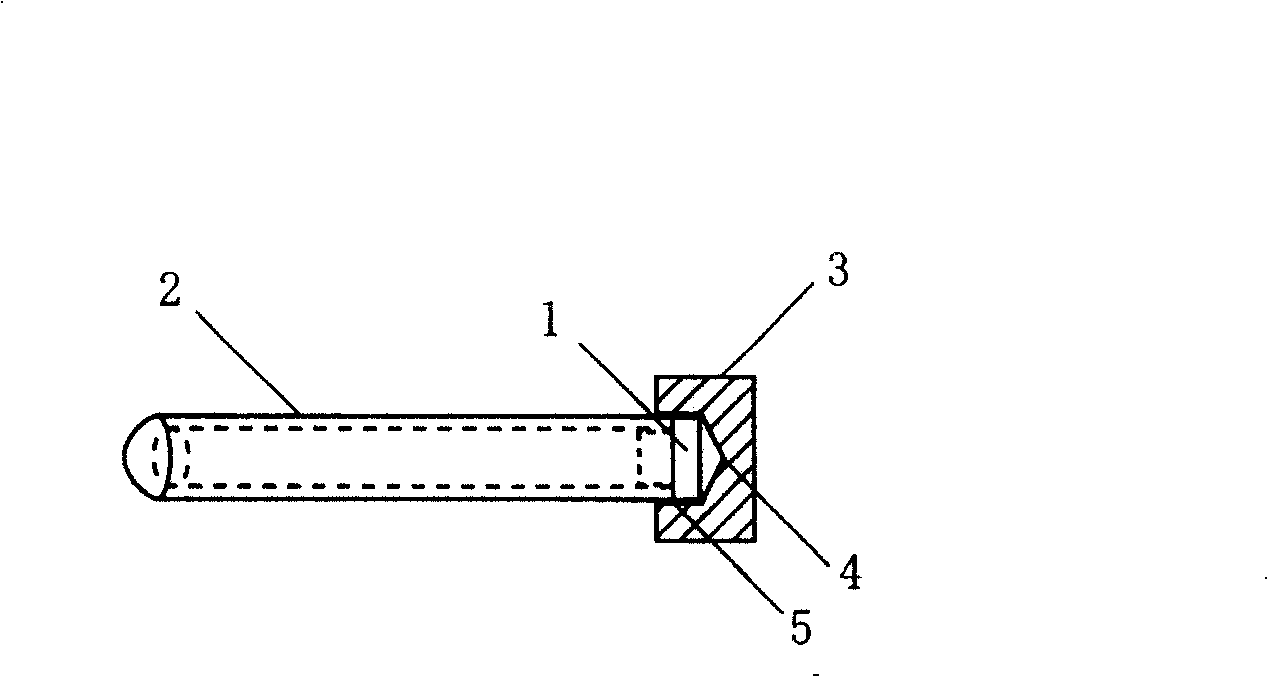

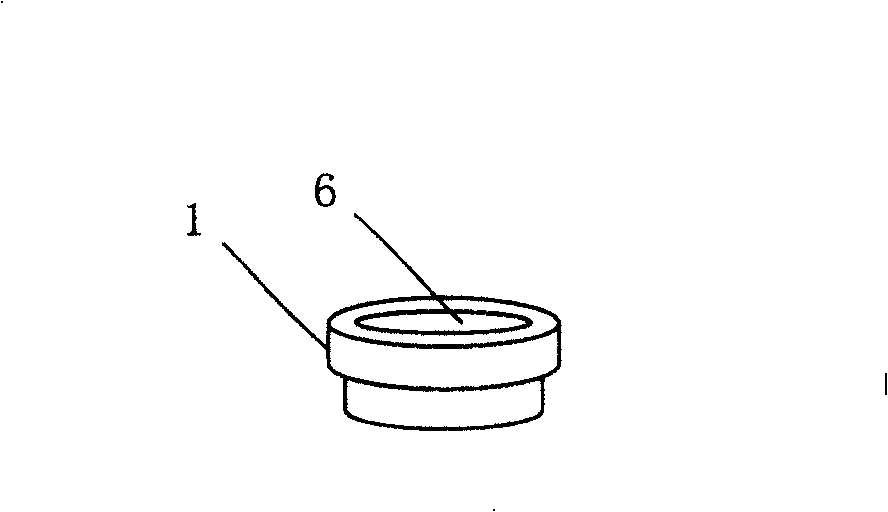

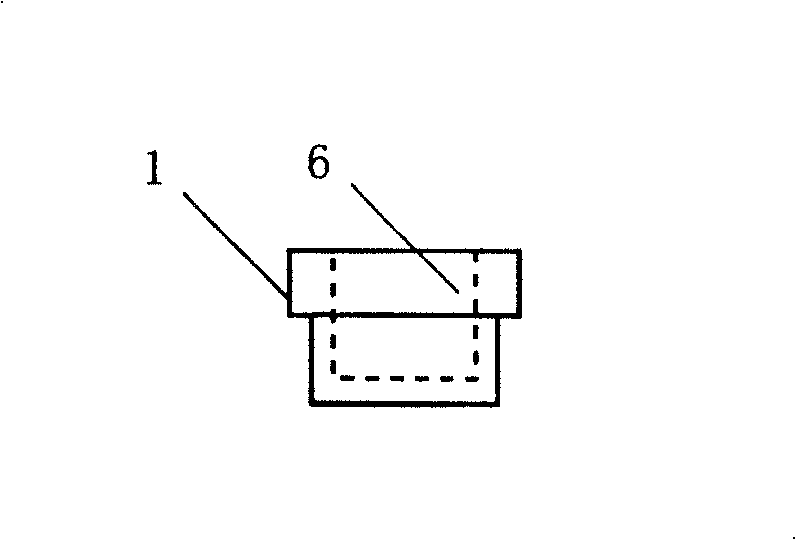

[0017] Such as figure 1 As shown, 1 is a "convex" shaped plug, 2 is a chemiluminescent tube, 3 is a heating device, 4 is a blind hole arranged on the heating device, and 5 is the inner wall of the blind hole 4. in such as figure 1 In the welding method shown, after plugging the opening end of the chemiluminescent tube 2 with the small end of the "convex" shaped plug 1, the blind hole 4 on the heating device 3 is used to fasten the chemical luminescent tube inserted with the plug 1. The end of the luminescent tube 2; the inner end of the blind hole 4 presses the end face of the big end of the plug 1, and the inner wall 5 of the blind hole 4 wraps the outer wall of the end of the luminescent tube 2; the big end of the plug 1 and the area at the end of the chemiluminescent tube 2 begins to melt, after the melting material of the plug 1 and the molten material at the end of the chemiluminescent tube 2 are fused, the heating device 3 is cooled, and the melted material is solidifie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com