Preparation method of formaldehyde electrochemical sensor membrane electrode

A membrane electrode and electrochemical technology, applied in the direction of electrochemical variables of materials, nanotechnology for sensing, nanotechnology, etc., to achieve the effect of reducing the preparation process, high conductivity, and high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

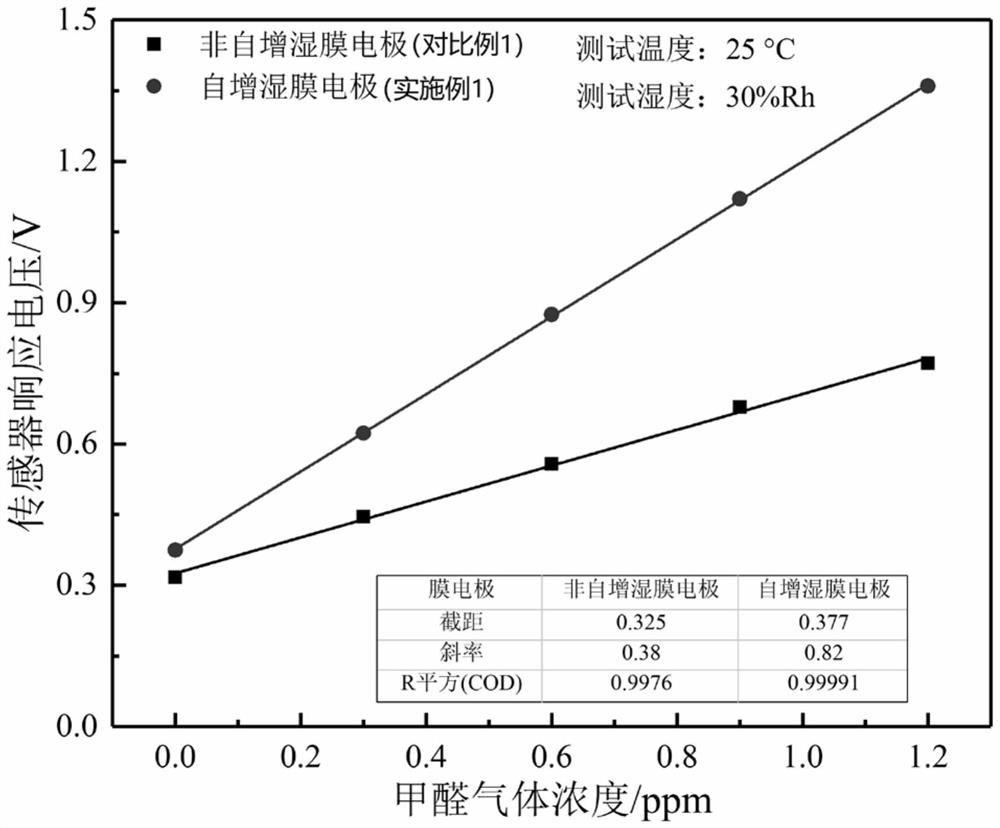

Embodiment 1

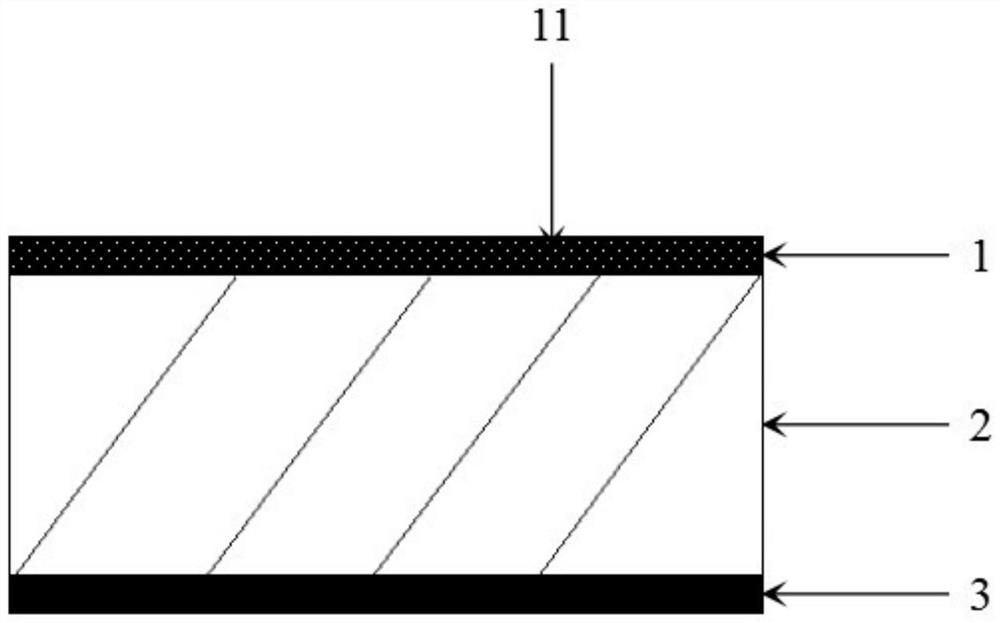

[0036] Such as figure 1 As shown, a formaldehyde electrochemical sensor membrane electrode includes a self-humidifying working electrode film 1 , a solid electrolyte film 2 and a counter electrode film 3 , wherein the self-humidifying working electrode film 1 contains a hydrophilic material layer 11 .

[0037] The preparation method of formaldehyde electrochemical sensor membrane electrode comprises:

[0038] 1) Weigh 100 mg of the first catalyst, add 5 mL of deionized water for wetting, add 10 mL of ethanol and stir evenly, then add 2.5 mL of Nafion emulsion and stir evenly, and mix evenly to prepare counter electrode slurry A;

[0039] 2) Weigh 100mg of the second catalyst, add 5mL of deionized water to wet it, add 10mL of ethanol and stir evenly, then add 2.5mL of Nafion emulsion and stir evenly, after mixing evenly, take 50mL of electrode slurry and add nano-SiO 2 (content is 40wt%), mixed uniformly to obtain self-humidifying electrode slurry B;

[0040] 3) Print or smea...

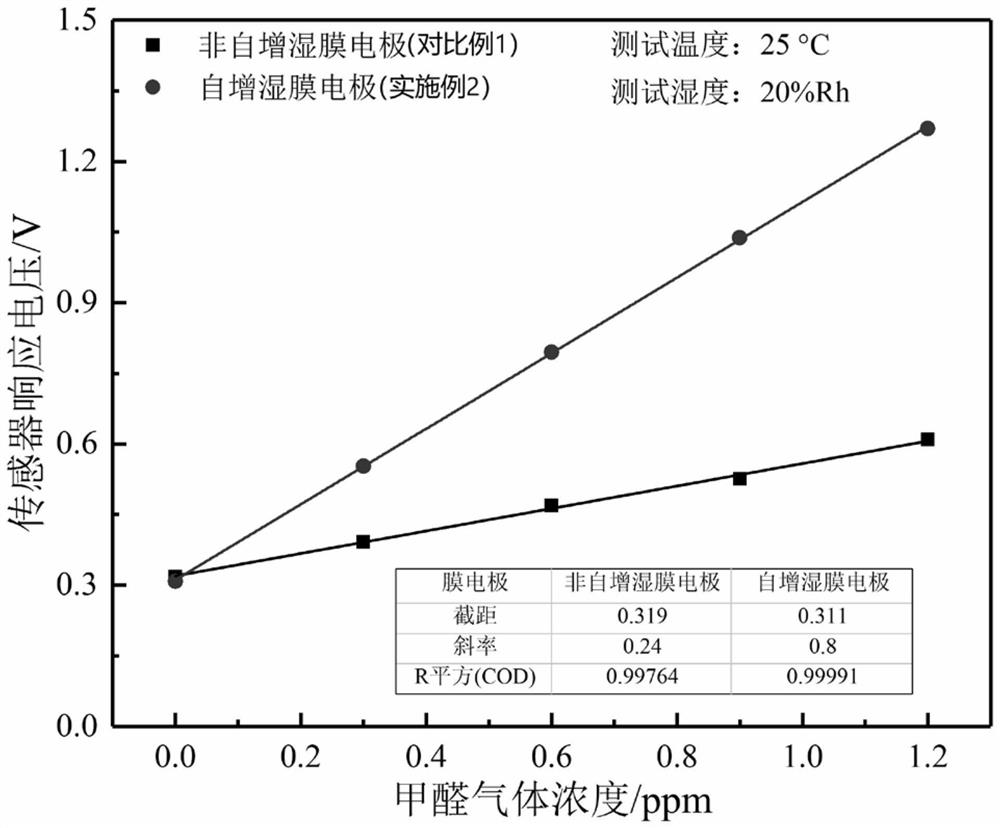

Embodiment 2

[0043] Such as figure 1As shown, a formaldehyde electrochemical sensor membrane electrode includes a self-humidifying working electrode film 1 , a solid electrolyte film 2 and a counter electrode film 3 , wherein the self-humidifying working electrode film 1 contains a hydrophilic material layer 11 .

[0044] The preparation method of formaldehyde electrochemical sensor membrane electrode comprises:

[0045] 1) Weigh 100mg of the first catalyst, add 4mL of deionized water to wet it, add 15mL of ethylene glycol and stir evenly, then add 2mL of polytetrafluoroethylene emulsion and stir evenly, and mix evenly to prepare electrode slurry A;

[0046] 2) Weigh 100mg of the second catalyst, add 4mL of deionized water to wet it, add 15mL of ethylene glycol and stir evenly, then add 2mL of polytetrafluoroethylene emulsion and stir evenly, after mixing evenly, take 50mL of electrode slurry and add nano-SiO 2 (content is 30wt%), mixed uniformly to obtain self-humidifying electrode slur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com