Forging method for forged steel supporting rolls used for rolling mill of large-scale wide thick plates

A technology for plate rolling mills and back-up rolls, applied to metal processing equipment, etc., which can solve the problems of heavy weight, coarse and uneven cast structure, various microstructure inhomogeneities, and inability to meet the requirements of manufacturing large-scale back-up rolls, etc., to meet the requirements of structure and performance required effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The forging method of the forging steel support roll for the large-scale wide and heavy plate rolling mill of the present invention adopts a double vacuum steel ingot with a weight of not less than 250 tons, an average diameter of the ingot body not less than φ3300mm, and a height of the ingot body not less than 4000mm to manufacture the forged steel backup roll, including the following step:

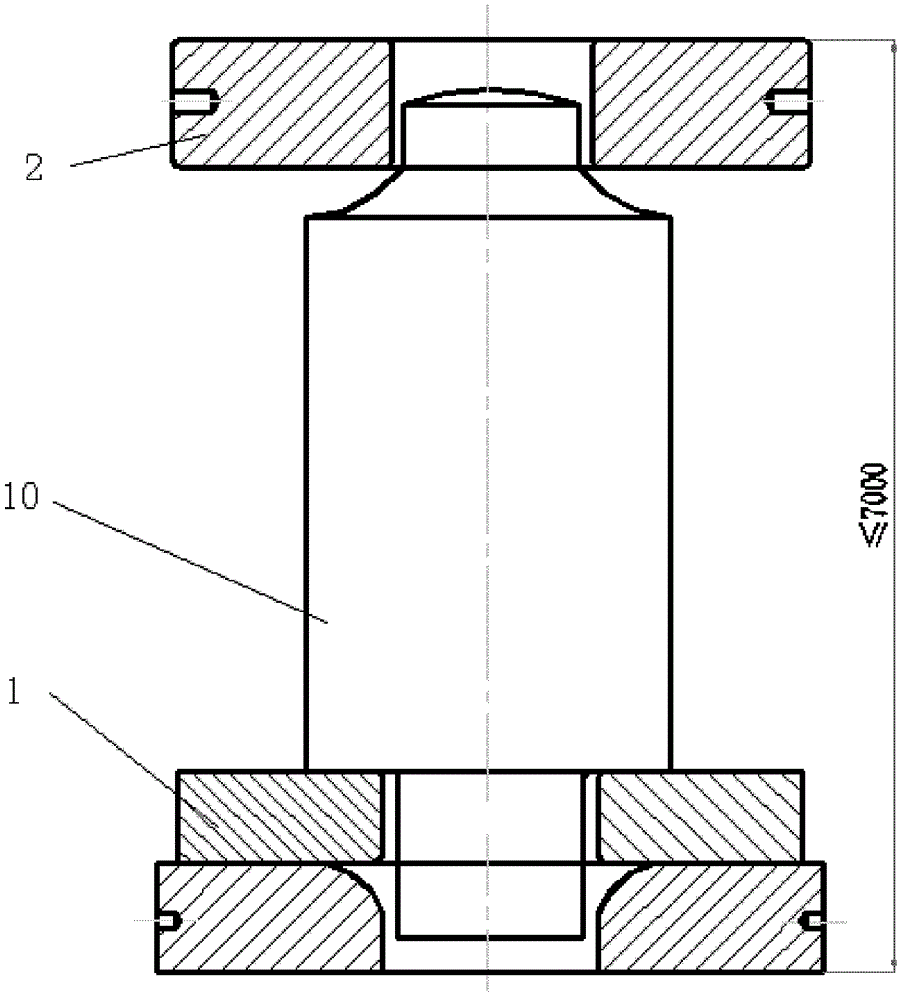

[0026] The first step is pre-drawing; the steel ingot is pretreated on the hydraulic forging press to remove the impurities of the steel ingot, so that the height of the ingot body is not more than 7000mm;

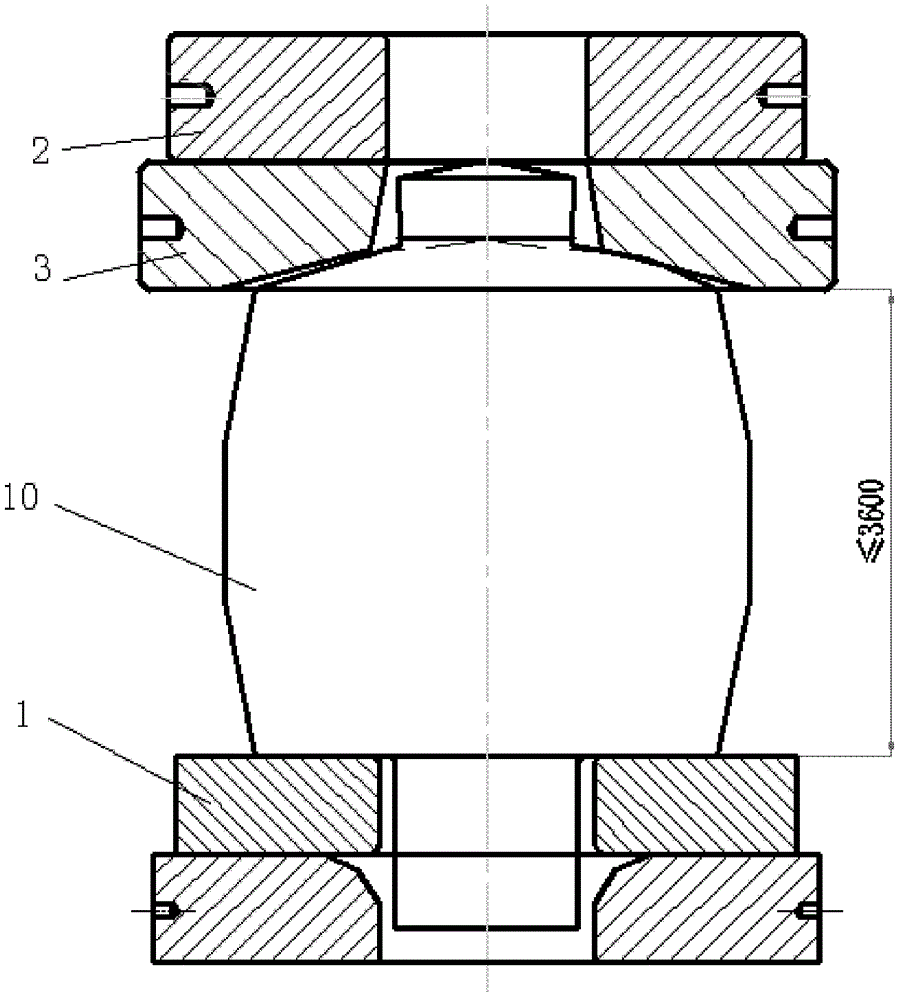

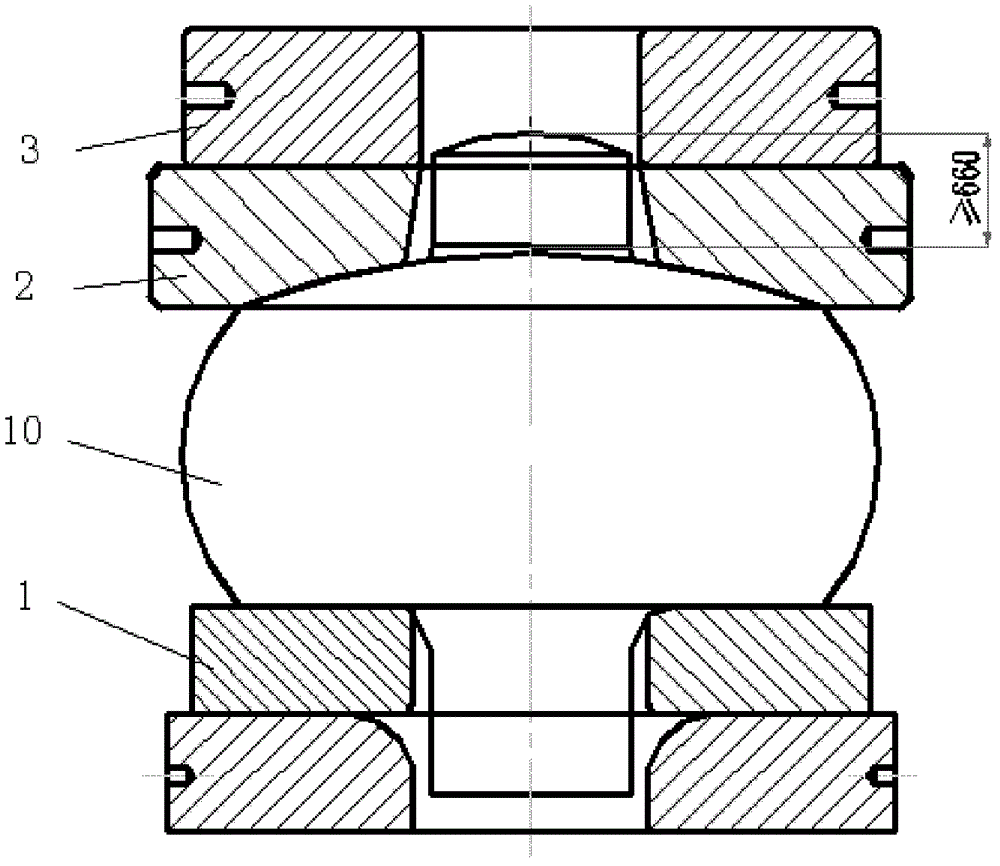

[0027] Press the steel ingot, then cut the handle, burn off the T shoulder, roll and chamfer, and cut the ingot tail so that the remaining height of the ingot tail is not less than 660mm;

[0028] The second step is upsetting; the steel ingot is kept at a temperature of 1200-1250°C for 30-50 hours, and then the upsetting plate tool is used to upset the steel ingot on a free forging ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com