Sheet molding compound (SMC) optical cable fiber distributing box

A fiber distribution box and optical cable technology, applied in the direction of fiber mechanical structure, etc., can solve the problems that affect the signal transmission effect, difficult to achieve tight fit, poor winding effect, etc., and achieve the effect of ensuring the quality of signal transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

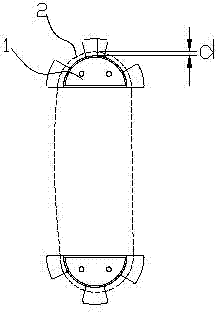

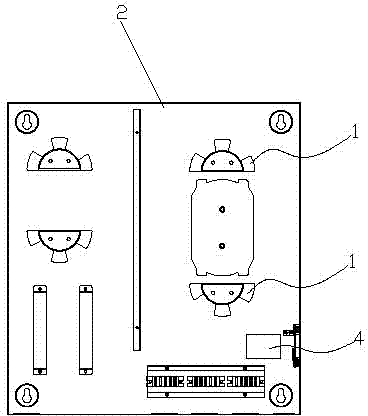

[0013] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment: see Figure 1 to Figure 4 , a fiber distribution box made of SMC material, including a box body 2, the box body material is made of SMC material, has excellent electrical insulation properties, mechanical properties, thermal stability, chemical corrosion resistance, and makes the box body service life Can reach more than 20 years.

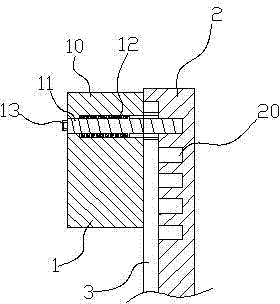

[0014] In the box body 2, arc-shaped winding boards 1 are set in pairs, and the arc-shaped winding boards 1 include a sleeve 10 and a stopper rod 11. A pull ring 13 is set on the outer wall of the stopper rod 11 for easy pulling. The stopper rod 11 provides a force point, the stopper rod 11 is inserted in the sleeve 10, a spring 12 is arranged in the sleeve 10, one end of the spring 12 is against the stopper rod 11, and the other end 12 of the spring is against the Lean against the inner wall of the sleeve 10 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com