Spring positioning device and spring positioning method

A spring positioning and fixing device technology, applied in metal processing equipment and other directions, can solve the problems of time-consuming and laborious, reduce the production efficiency of spring mattresses, etc., and achieve the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

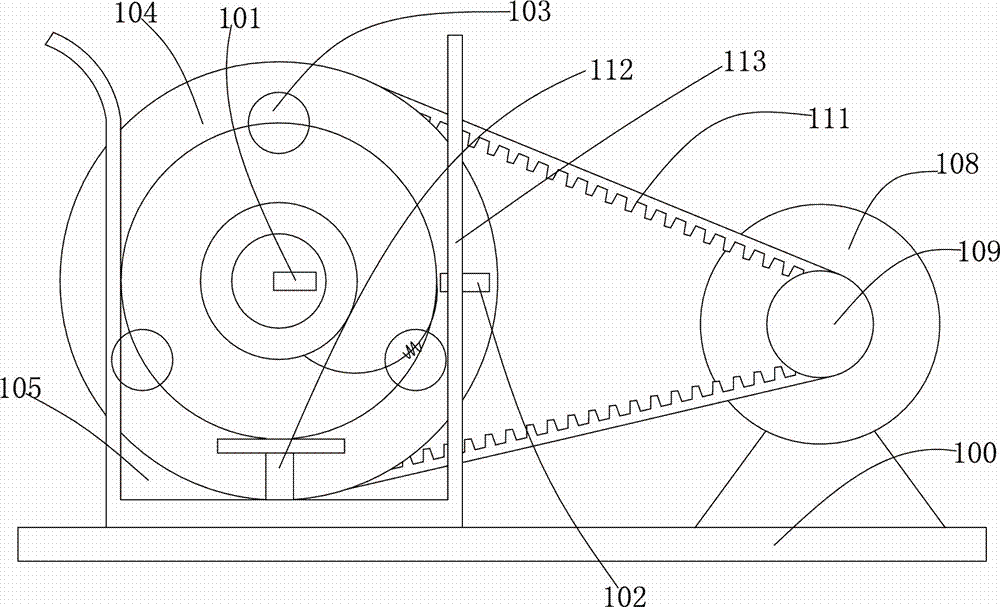

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments: In this embodiment, the side of the plate 104 facing the spring 2 is defined as the front of the plate, and the side of the plate 104 facing away from the spring 2 is defined as the back.

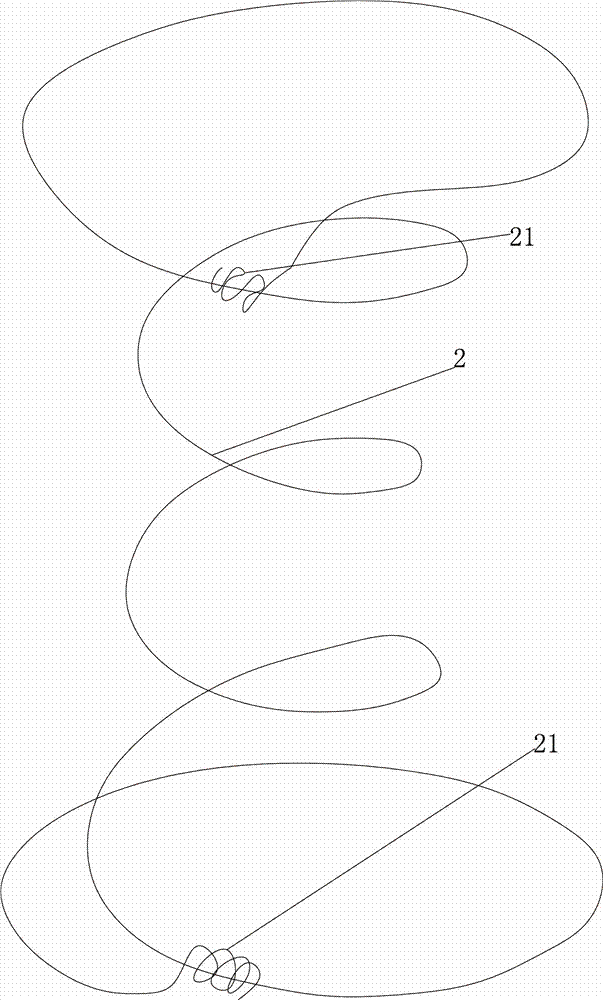

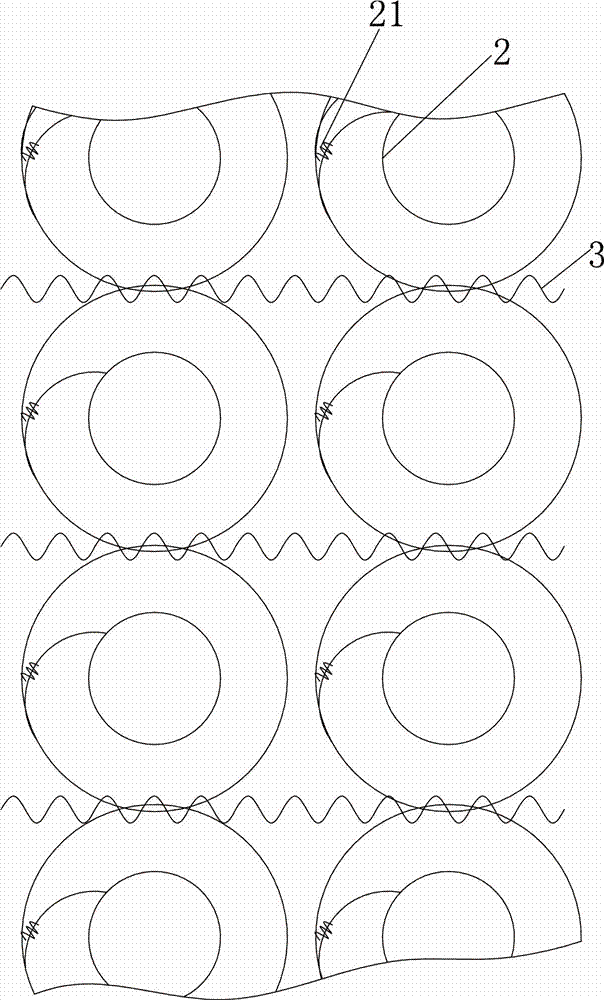

[0018] see image 3 and Figure 4 , a spring positioning device, including a base 100, a base 106 and a motor 108 are fixed on the base 100, one end of a rod 107 is fixed on the base 106, and a circular plate 104 is connected to the other end of the rod 107 in rotation, and the plate 104 The center of circle is located on the axis of the rod 107, and an emitter 101 is fixed on the end face of the rod 107, and the main part of the emitter 101 is a luminous tube. Three electromagnets 103 are fixed on the plate 104 , and the electromagnets 103 and the plate 104 together form a fixing device for the spring 2 . Its working principle is that the spring 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com