Floor lock assembly for high-strength vehicle seat

A car seat and floor lock technology, which is applied to vehicle seats, vehicle parts, special positions of vehicles, etc., can solve the problem of lowering production efficiency, does not adopt an anti-mislocking structure, and has low locking strength that cannot meet high-strength seats. and other problems, to achieve the effect of improving production efficiency, adjustable assembly strength, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

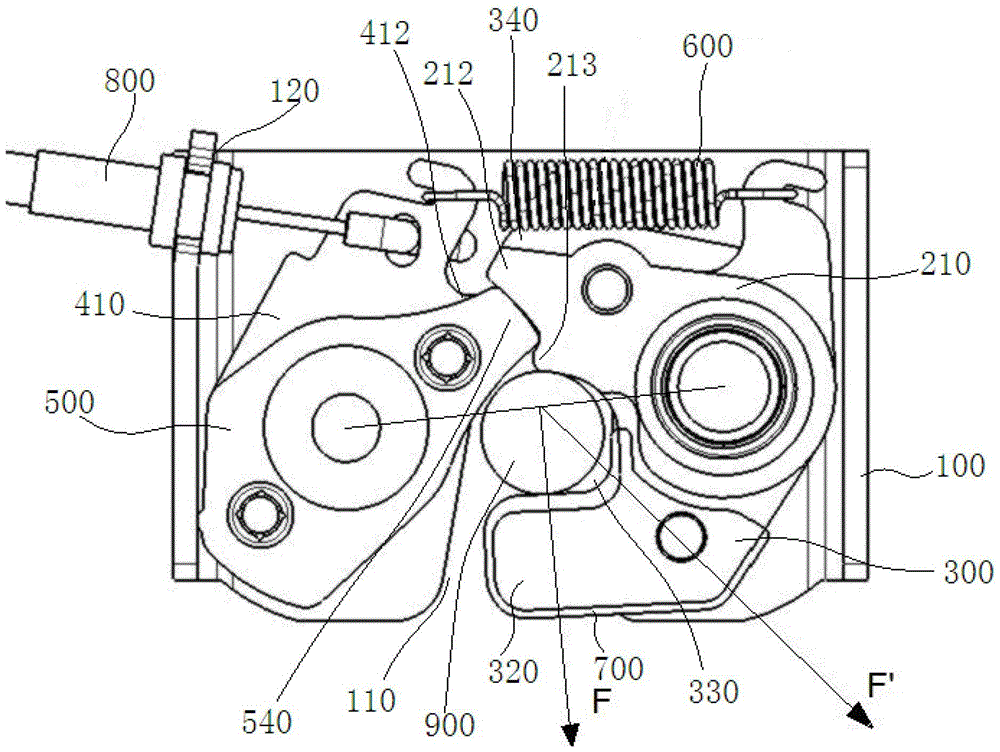

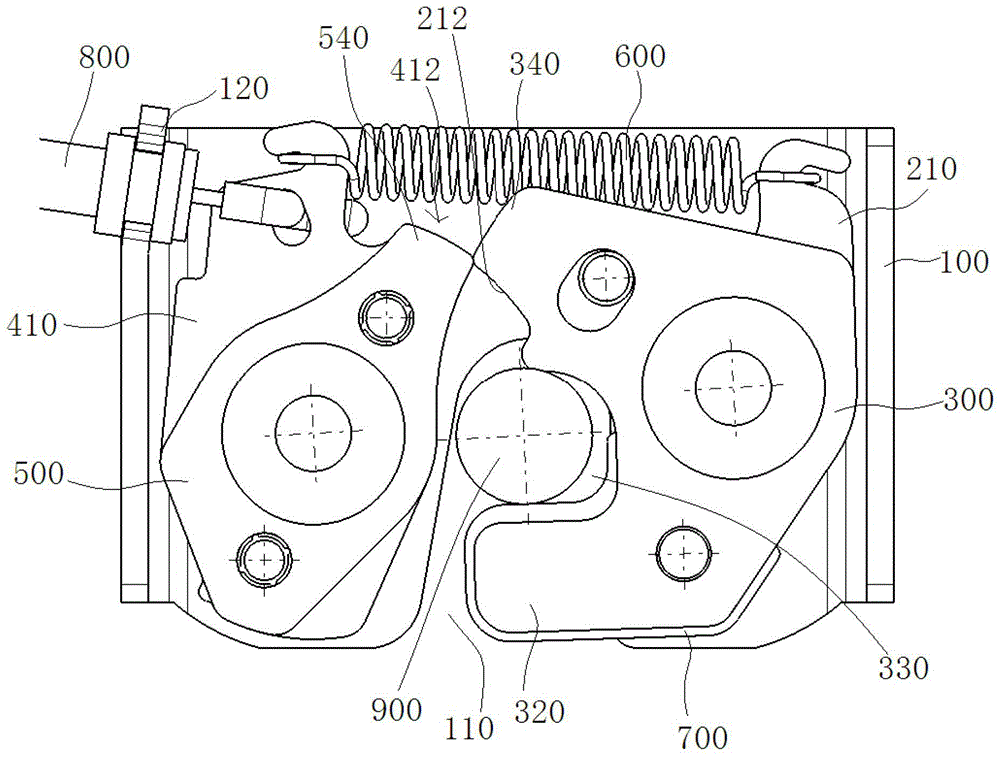

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

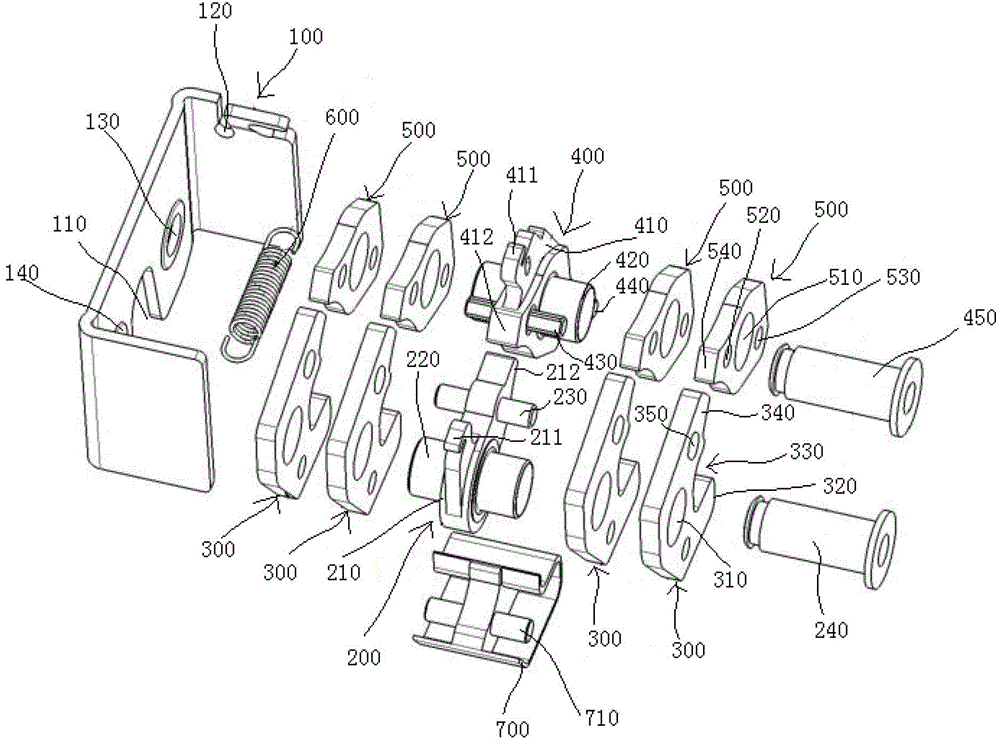

[0029] see figure 1 , the high-strength car seat floor lock assembly shown in the figure includes a bottom plate 100, which is made of metal material and has a U-shaped structure. A lock bar receiving opening groove 110 and a The cable mounting slot 120 and two anchor holes 130, 140 for installing the unlocking cable. The opening of the locking bar receiving slot 110 faces downward.

[0030] The core parts of the high-strength car seat floor lock assembly are a pawl bracket 200, four pawl plates 300, a cam support 400, and four cam plates 500. Of course, the number of pawl plates 300 and cam plates 500 can be Make adjustments, such as two pieces, three pieces, five pieces, etc., to meet the strength requirements of different car seats.

[0031] In order to eliminate the abnormal sound produced by the rigid connection and effectively eliminat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com