Early expanding material for cement injection material and preparation method thereof

A technology of expanding materials and pouring materials, which is applied in the field of early expanding materials and their preparation, can solve the problems of uncontrollable gas generation at ambient temperature, etc., and achieve the effects of improving early volume stability, low cost, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

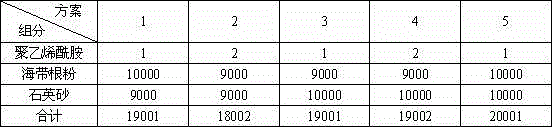

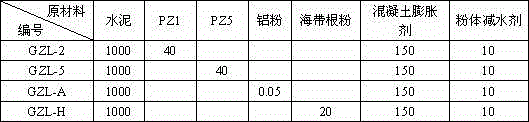

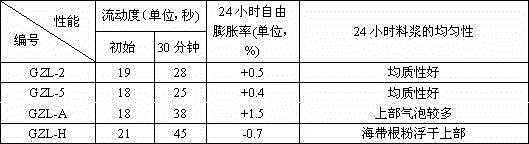

[0018] According to the ratio of raw materials in Table 1, a series of early expansion materials for cement grout were prepared respectively.

[0019] Table 1 The formula of the early expansion material of this cement pouring material (mass ratio, unit: part)

[0020]

[0021] According to the material formula in Table 1, first dissolve 1-2 parts of polyvinylamide in 1000 parts of water to make a polyvinylamide aqueous solution with a mass concentration of 1 / ‰-2 / ‰ and stir evenly, then mix 1000 parts according to the mass ratio 1 part of the polyvinylamide aqueous solution is uniformly mixed with 9000-10000 parts of kelp root powder, then evenly mixed with 9000-10000 parts of quartz sand, and finally the obtained mixture is dried to obtain the patented product.

[0022] Beneficial effect

[0023] Generally, concrete expansion agent is usually added to cement pouring material to offset the long-term shrinkage of cement after hardening. At the same time, polycarboxylate pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com