Application of eutectic ionic liquid/molecular sieve composite material in CO2 capture

A technology of ionic liquids and composite materials, applied in the fields of new materials, carbon neutralization, and carbon peaking, to achieve the effects of simple process, convenient preparation, and safe and stable post-processing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

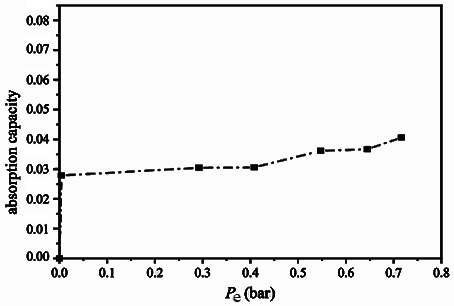

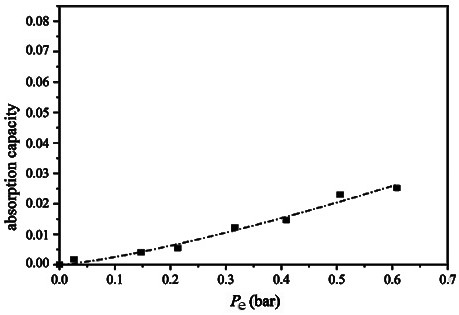

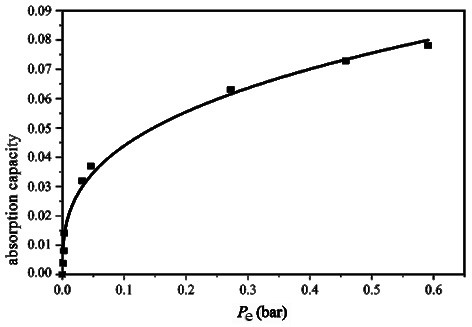

Image

Examples

Embodiment 1

[0020] Preparation of YCTC-3: Add 1.0 g molecular sieve 13Z (sodium Z type), 1.3 g guaiacol, and 50 g deionized water to the reaction kettle in sequence, stir for 1–2 h at normal temperature and pressure, and then Carry out temperature program with a heating rate of 1 ℃ / min, heat up to 40-50 ℃, keep warm and continue to stir for 8 h, then naturally cool to room temperature under stirring conditions, add 1.0 g of tetraethylenepentamine, and then carry out program-controlled temperature rise. The rate is 0.5 ℃ / min, and the temperature is slowly raised to 40-50 ℃. Stirring is continued at a constant temperature for 12-15 h, then the stirring is stopped and naturally cooled to room temperature for overnight. The resulting mixture is simply filtered or suction filtered, and the solid product is vacuum-dried at 100 ℃ for 2 h to obtain the composite material YCTC-3; the loading amount of the ionic liquid DES is 20% of the mass of the molecular sieve.

Embodiment 2

[0022] Preparation of YCTC-3: Add 1.0 g molecular sieve 5A (calcium A type), 1.0 g choline chloride, and 15 g deionized water to the reaction kettle in turn, stir for 1–2 h at normal temperature and pressure, and then Carry out temperature program with a heating rate of 1 ℃ / min, raise the temperature to 40-70 ℃, keep warm and continue to stir for 8 h, then cool down to room temperature naturally under stirring conditions, add 1.0 g of ethylene glycol, and then carry out program-controlled heating, heating rate 0.5 ℃ / min, slowly increase the temperature to 40-70 ℃, continue to stir at a constant temperature for 8-15 h, then stop stirring and naturally cool to room temperature overnight, the resulting mixture is simply filtered or suction filtered, and the solid product is vacuum-dried at 100 ℃ for 2 h The composite material YCTC-3 was obtained; the loading amount of ionic liquid DES was 11% of the mass of molecular sieve.

Embodiment 3

[0024] Preparation of YCTC-3: Add 1.0 g molecular sieve 4A (sodium type A), 1.0 g amino acid, and 50 g deionized water into the reaction kettle in turn, stir for 24 h under normal temperature and pressure conditions, and then carry out temperature programming. The rate is 0.5 ℃ / min, heat up to 40~70 ℃, keep warm and continue to stir for 10~15 h, stop stirring and naturally cool to room temperature overnight, the resulting mixture is simply filtered or suction filtered, and the solid product is vacuum dried at 100 ℃ The composite material YCTC-3 of DES and molecular sieve was obtained in 2 h; the loading amount of DES was 12 % of the mass of molecular sieve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com