A kind of anti-montmorillonite high-efficiency amphoteric polycarboxylate water reducer and preparation method thereof

An amphoteric polycarboxylic acid and a water reducing agent technology, applied in the field of concrete water reducing agent, can solve problems such as unfavorable industrial production, cost increase, increase production cost, etc., and achieve the advantages of less addition, high water reduction rate and simple synthesis method. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Dissolve 0.01mol monomer HPEG-2400 in 20mL distilled water to obtain HPEG-2400 solution; dissolve 0.027mol acrylic acid and 0.003mol SPB in 20mL distilled water to obtain a mixed monomer solution; dissolve 0.80g ammonium persulfate in 24mL of distilled water to obtain a catalyst solution;

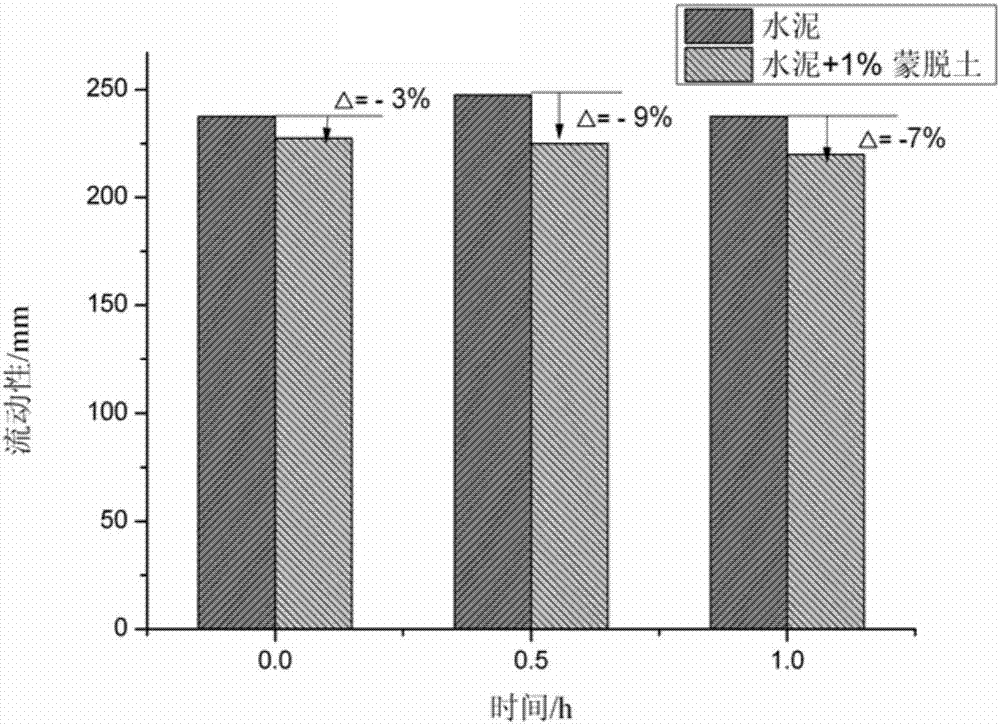

[0030](2) Heat the HPEG-2400 solution to 80°C, then drop the mixed monomer solution and the catalyst solution into the HPEG-2400 solution at the same time, and the dropping speed of the mixed monomer solution and the catalyst solution are both 0.6mL / min, The reaction time is 5 hours, the pH is adjusted to 7±1 with a saturated sodium hydroxide solution, and the product concentration is controlled to 30%, so as to obtain a high-efficiency amphoteric polycarboxylate water-reducer resistant to montmorillonite. The water reducing rate of the water reducing agent is 37%; the initial fluidity without clay (montmorillonite) is 247.5mm, and the initial fluidity is reduced by 3% when 1% cl...

Embodiment 2

[0032] (1) Dissolve 0.01mol monomer APEG-2400 in 20mL distilled water to obtain APEG-2400 solution; dissolve 0.018mol acrylic acid and 0.012mol SPB in 28mL distilled water to obtain a mixed monomer solution; dissolve 0.86g ammonium persulfate in 24mL of distilled water to obtain a catalyst solution;

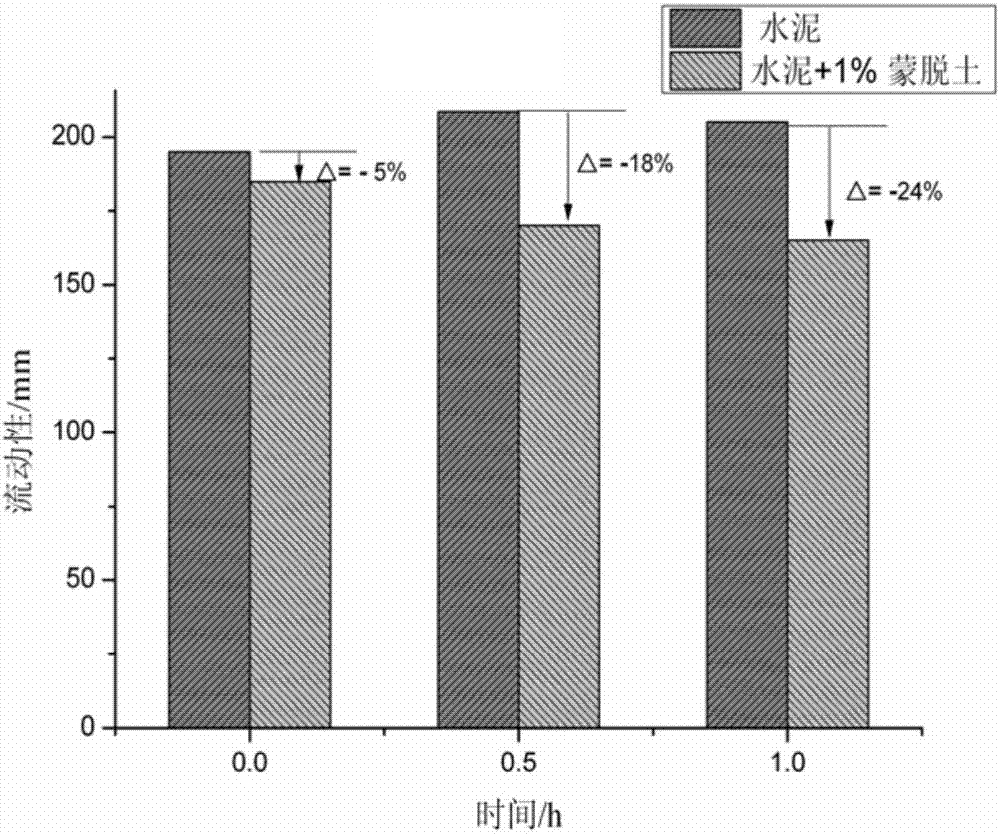

[0033] (2) Heat the APEG-2400 solution to 80°C, then drop the mixed monomer solution and catalyst solution into the APEG-2400 solution at the same time, the dropping speed of the mixed monomer solution and catalyst solution is 0.7mL / min, The reaction time is 4 hours, the pH is adjusted to 7±1 with a saturated sodium hydroxide solution, and the product concentration is controlled to 30%, to obtain a high-efficiency amphoteric polycarboxylate water-reducer resistant to montmorillonite. The water reducing rate of the water reducing agent is 28%, the initial fluidity without clay is 200mm, and the initial fluidity is reduced by 5% when 1% clay is added.

Embodiment 3

[0035] (1) Dissolve 0.01mol monomer TPEG-2400 in 20mL distilled water to obtain TPEG-2400 solution; dissolve 0.024mol methacrylic acid and 0.006mol SPB in 25mL distilled water to obtain a mixed monomer solution; dissolve 0.93g ammonium persulfate Dissolve in 28mL distilled water to obtain a catalyst solution;

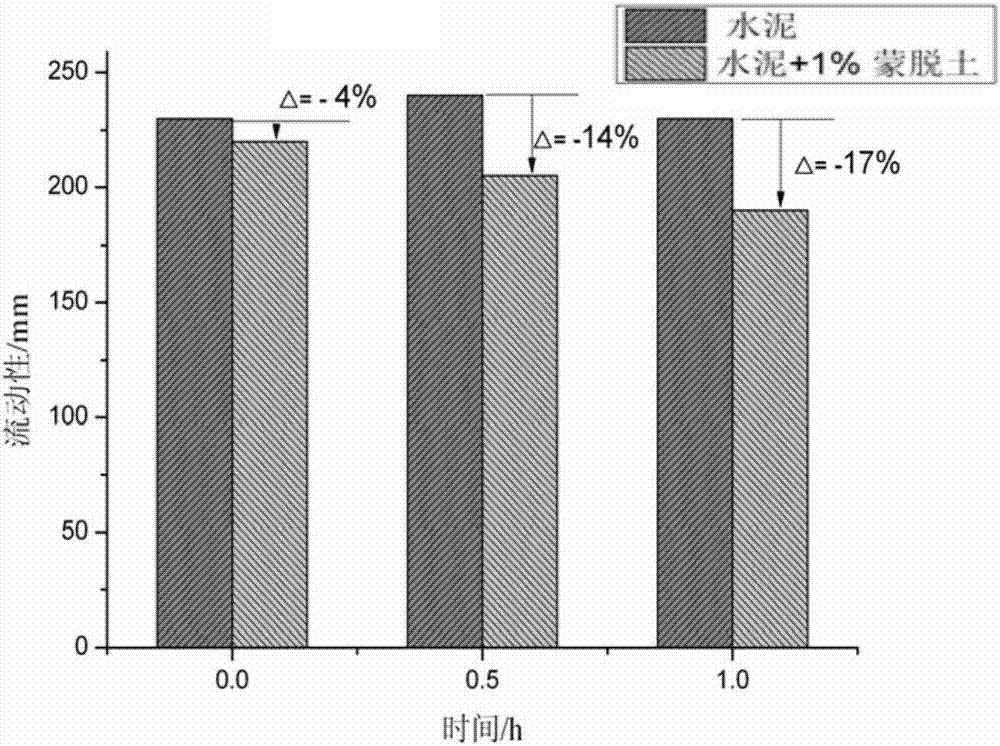

[0036] (2) Heat the TPEG-2400 solution to 90°C, then drop the mixed monomer solution and the catalyst solution into the TPEG-2400 solution at the same time, the dropping speed of the mixed monomer solution and the catalyst solution are both 0.5mL / min, The reaction time is 6 hours, the pH is adjusted to 7±1 with a saturated sodium hydroxide solution, and the product concentration is controlled to 30%, so as to obtain a high-efficiency amphoteric polycarboxylate water-reducer resistant to montmorillonite. The water reducing rate of the water reducing agent is 34%, the initial fluidity without clay is 230mm, and the initial fluidity is reduced by 4% when 1% clay is added. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com