Application of ionic liquid composite metal framework material to NO capture

A metal frame material and ionic liquid technology, applied in the fields of new materials, resources and the environment, can solve the problems of few applications and difficult implementation, and achieve the effects of simple operation process, improved absorption effect, and convenient preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

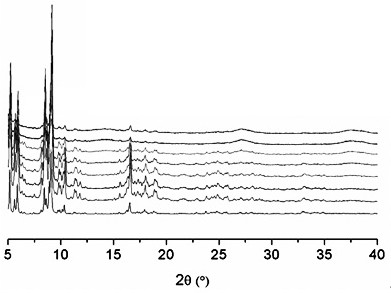

[0020] Preparation of MIL-101-Cr: CrCl 3 ·6H 2 O (2.66 g, 0.01 mol), terephthalic acid (1.66 g, 0.01 mol), 1-butyl-3-methylimidazole hydrochloride (0.1 g) and 80 mL of high-purity water were added to 100 mL of The sealed reactor was placed in a 200 °C oven for 10 h in a polytetrafluoroethylene liner. After the solution was naturally cooled to room temperature, it was washed with high-purity water and absolute ethanol three times, and finally vacuum-dried at 100 °C. After drying in the oven for 2 h, 3.0 g of a light green powder sample was obtained, which was named MIL-101-Cr.

[0021] Preparation of IL-MIL-101-Cr: Add 1.0 g of MIL-101-Cr obtained in the previous step, 1.0 g of tetraethylenepentamine, and 30 g of toluene to the reactor in sequence, and stir for 2 h at normal temperature and pressure Afterwards, the temperature was programmed at a rate of 1 °C / min, and the temperature was raised to a constant temperature of 80 °C and continued to stir for 8 h, then naturally c...

Embodiment 2

[0023] Preparation of IL-MIL-101-Cr: Add 1.0 g of MIL-101-Cr obtained in Example 1, 1.0 g of triethylenetetramine, and 25 g of toluene to the reaction kettle in sequence, and stir for 2 h at normal temperature and pressure. Carry out the temperature program, the heating rate is 1 ℃ / min, the temperature is raised to 80 ℃ and the constant temperature is continued to stir for 8 h, and then it is naturally cooled to room temperature under the condition of stirring, and the equimolar amount of guaiacol and triethylenetetramine is added, and then the program is controlled. Heat up at a rate of 0.5 °C / min, slowly increase the temperature to 80 °C, continue to stir at a constant temperature for 15 h, then stop stirring and naturally cool to room temperature overnight. Vacuum drying at 60 °C for 2 h yielded 1.35 g of off-white composite material IL-MIL-101-Cr. Therefore, it can be calculated that the loading of ionic liquid IL is 35% of the mass of MIL-101-Cr as the metal frame material...

Embodiment 3

[0025] Preparation of IL-MIL-101-Cr: 1.0 g of MIL-101-Cr obtained in Example 1, 0.5 g of tetraethylenepentamine, 0.5 g of triethylenetetramine, and 30 g of toluene were added to the reaction kettle in sequence, and the After stirring for 2 h under normal pressure, the temperature was programmed at a rate of 1 °C / min. The temperature was raised to a constant temperature of 80 °C and continued to stir for 8 h. Then, it was naturally cooled to room temperature under stirring conditions, and guaiac wood and polyamine were added. phenol, then proceed to program-controlled temperature rise at a rate of 0.5 °C / min, slowly increase the temperature to 80 °C, continue to stir at a constant temperature for 15 h, then stop stirring and naturally cool to room temperature overnight. Water was washed three times respectively, and vacuum-dried at 60 °C for 2 h to obtain 1.43 g off-white composite material IL-MIL-101-Cr, so it can be calculated that the loading capacity of ionic liquid IL is MI...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com