Lock nut special for motor vehicle

An anti-loosening, motor vehicle technology, applied in the direction of nuts, screws, bolts, etc., can solve the problems of cumbersome nut detection and reinforcement, achieve high safety, improve bonding effect, and improve safety effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

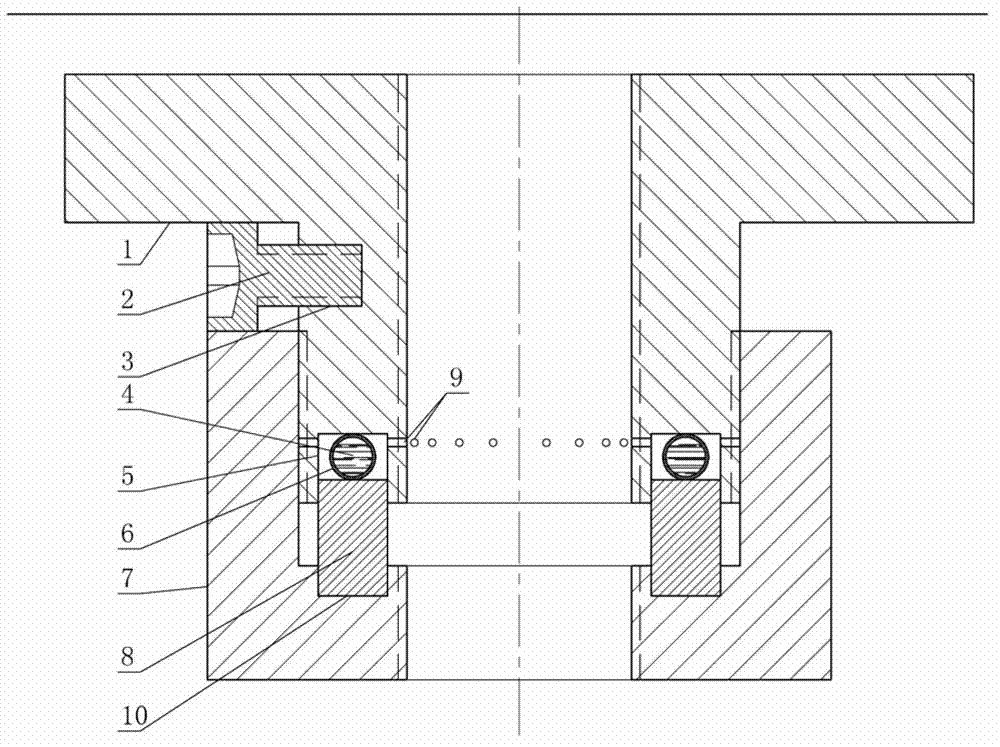

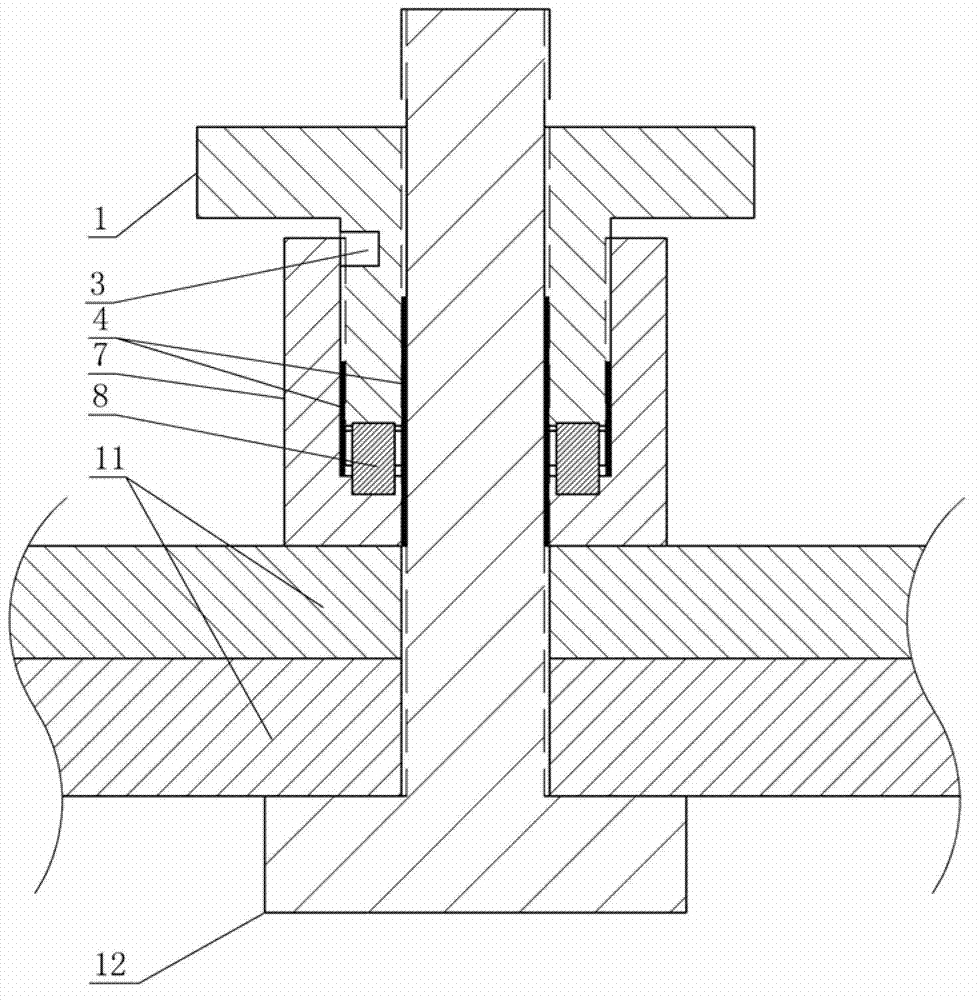

[0019] The special anti-loosening nut for motor vehicles consists of a main nut 1, a limit screw 2, a limit screw hole 3, 502 glue 4, a crushing groove 5, a rubber storage strip 6, an auxiliary nut 7, a top pressure ring 8, a glue discharge hole 9 and Ring groove 10 constitutes.

[0020] Wherein, the interior of the main nut 1 has a longitudinally through screw hole. On the bottom surface of the main nut 1, there is an annular crushing groove 5 with a rectangular cross section. The upper half of the main nut 1 is hexagonal, and the lower half of the main nut 1 is cylindrical. The outer wall of the cylindrical It is threaded and has a transverse limit screw hole 3 , the inner end of the limit screw 2 is in the limit screw hole 3 , and the outer end of the limit screw 2 is directly above the auxiliary nut 7 .

[0021] The auxiliary nut 7 is cylindrical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com