Deepwater sea floor reinforcing pipeline

A pipeline and deepwater technology, applied in the production, laying and installation of deepwater submarine pipelines, can solve the problems of significant pressure load, overall instability, and axial expansion of pipelines, so as to improve the critical pressure of axial overall buckling and improve resistance to external loads. Ability, bending stress reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described below in conjunction with the accompanying drawings and embodiments.

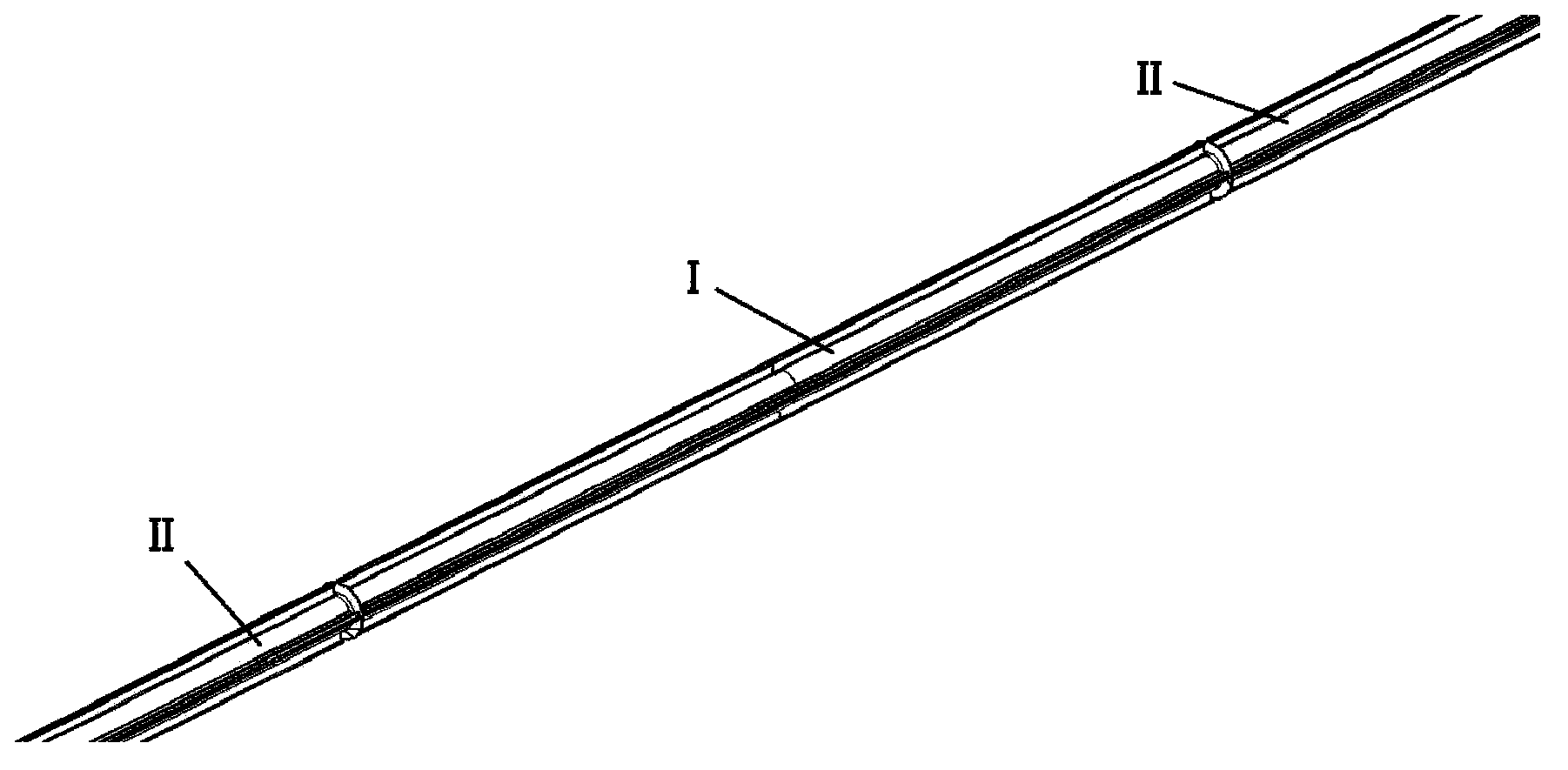

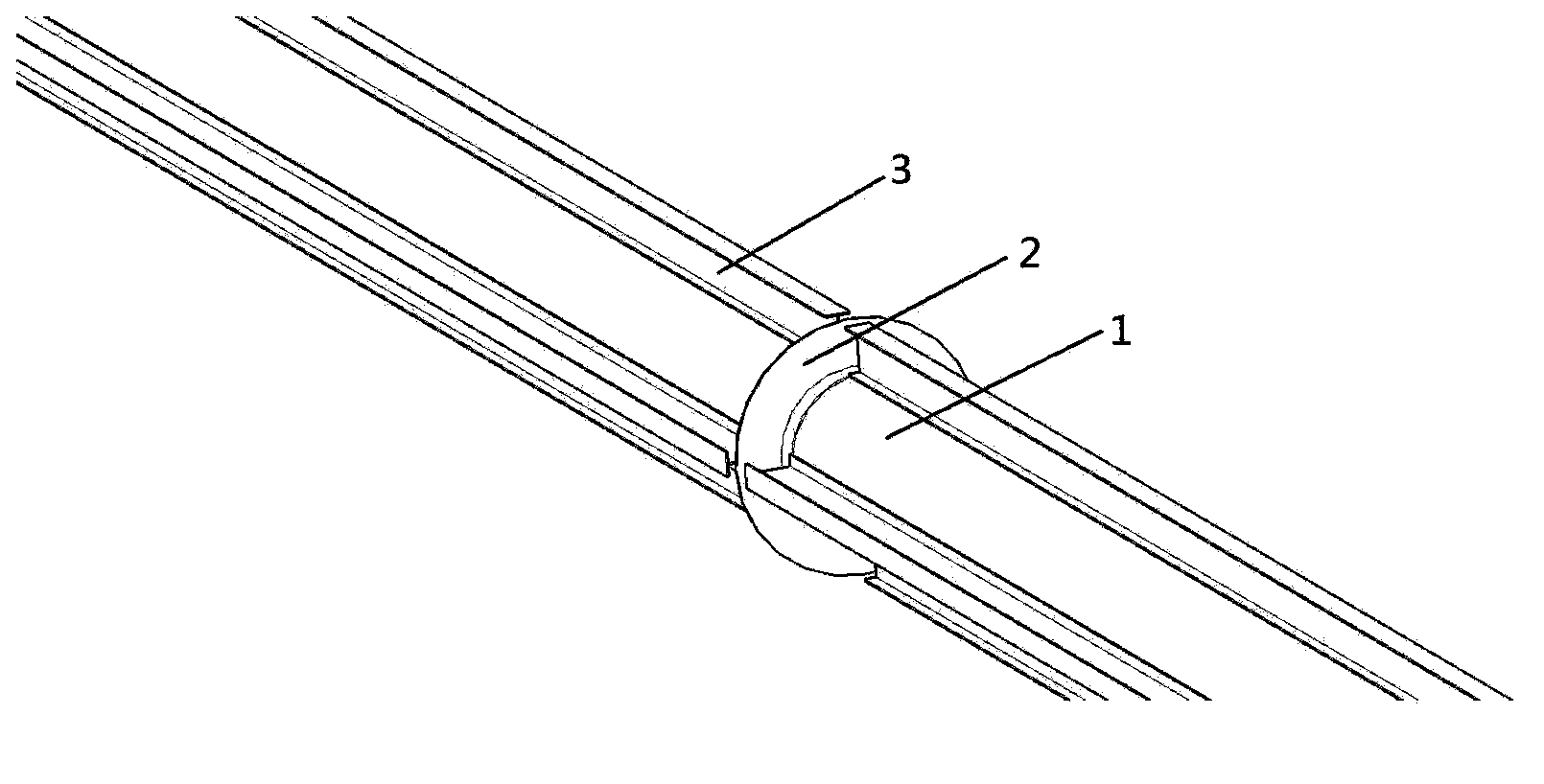

[0022] see figure 1 and figure 2 , The deep-water seabed reinforced pipeline provided by the present invention specifically includes transverse T-shaped ribs (circumferential skirts), and H-shaped ribs (longitudinal ribs) welded along the length of the pipe on the reinforced pipe section and its front and rear extension pipe sections. The installation location of the device is a safety reinforcement area with special strength requirements in deepwater submarine pipelines, including a reinforced pipe section I and an extended pipe section II before and after each, and the length of each pipe section does not exceed 12m. The two ends of the reinforced pipe fittings (1) are welded with circumferential T-shaped reinforcing materials, that is, the circumferential skirts (2), and between the two circumferential skirts (2) there are welded reinforced pipes at interv...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap