Prestressed recoverable steel compression bars constrained by clamp-type circular tubes

A prestressing and clamping technology, applied in the direction of truss structures, joists, girders, etc., can solve the problems of insufficient bearing capacity and residual deformation, and achieve the effect of increasing bearing capacity, reducing residual deformation, and improving collapse resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solution of the present application will be described in detail below in conjunction with the drawings.

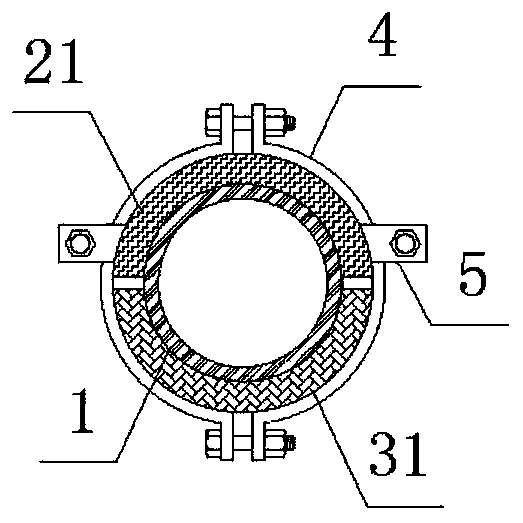

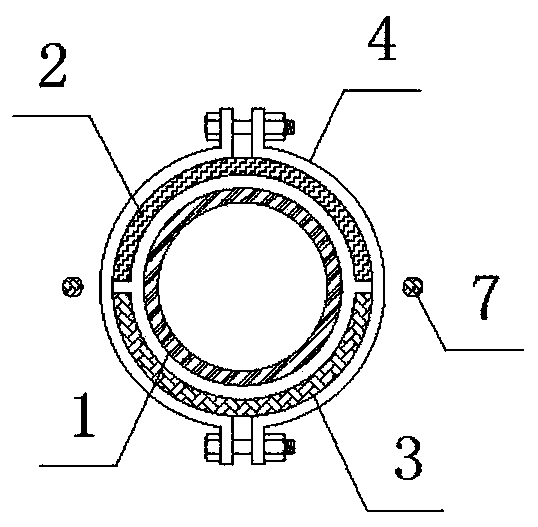

[0031] It should be noted that the left end of the upper semicircular restraint tube 2 and the left end of the lower semicircular restraint tube 3 are located at the same position in the length direction of the circular pressure tube 1, and the right end of the upper semicircular restraint tube 2 and the right end of the lower semicircular restraint tube 3 It is located at the same position in the length direction of the circular pressure tube 1.

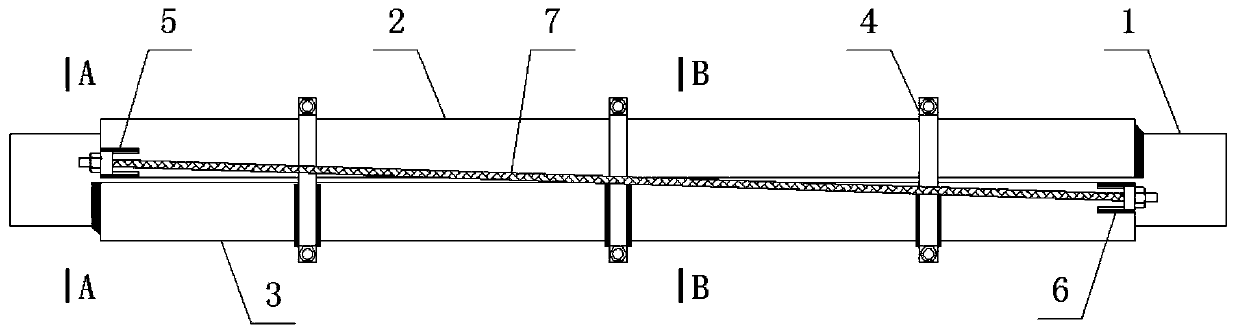

[0032] Such as Figure 1 ~ Figure 4 As shown, the pre-stressed recoverable steel compression rod using clamp-type round tube constraints of the present invention includes: circular compression tube 1, upper semicircular constraint tube 2, lower semicircular constraint tube 3, clamp 4, first stiffening lug plate 5. The second stiffening lug plate 6, the pre-tension rod 7, the upper sealing plate 21 and the lower s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com