Prestressed recoverable steel struts constrained by snap-in square tubes

A prestressed and snap-in technology, applied in truss structures, joists, girders, etc., can solve problems such as residual deformation and insufficient bearing capacity, reduce residual deformation, improve bearing capacity, and avoid compressive instability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

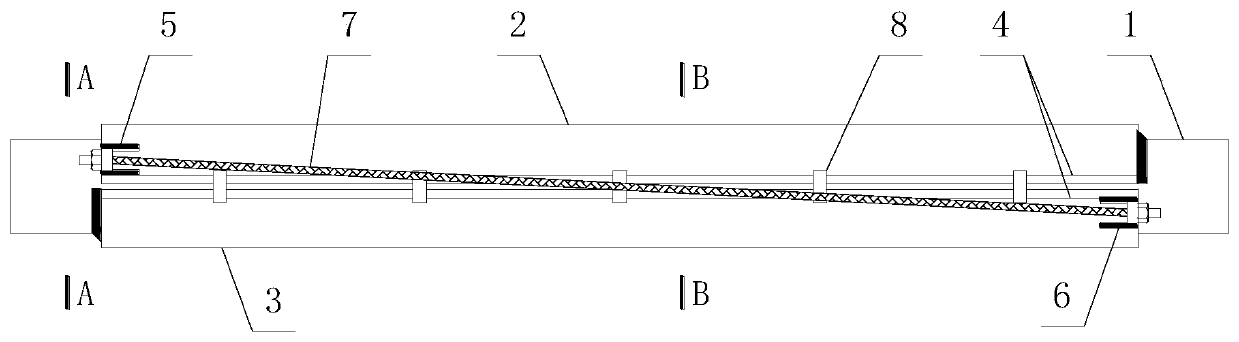

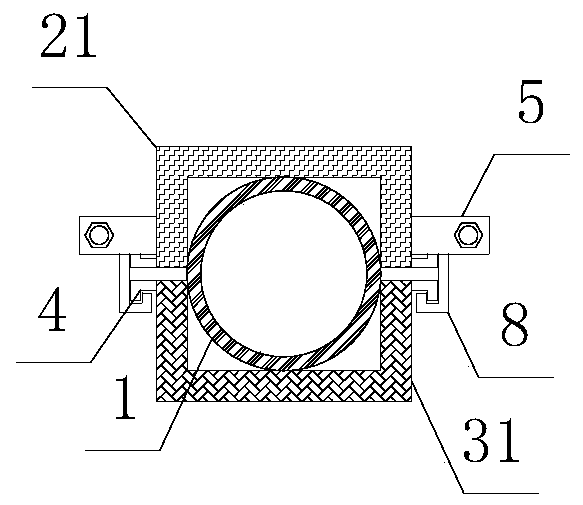

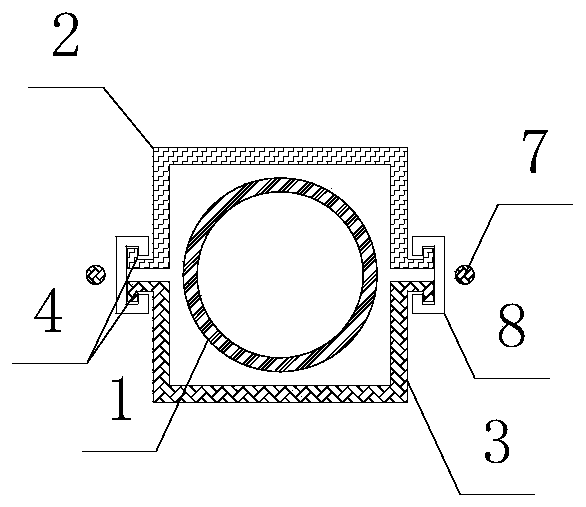

[0030] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0031] It needs special explanation: the left end of the upper groove-shaped restraint tube 2 and the left end of the lower groove-shaped restraint pipe 3 are located at the same position in the length direction of the circular pressure tube 1, and the right end of the upper groove-shaped restraint tube 2 is in the same position as the lower groove-shaped restraint pipe. The right end of the pipe 3 is located at the same position in the length direction of the circular pressure pipe 1 .

[0032] Such as Figure 1 ~ Figure 4 As shown, the prestressed recoverable steel pressure bar constrained by snap-in square tubes in this application includes: circular pressure tube 1, upper trough-shaped constraint tube 2, lower trough-shaped constraint tube 3, chute 4, first stiffening ear Plate 5, second stiffening lug plate 6, pre-tension rod 7, upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com