Method of strengthening deep water seafloor pipeline stability

A subsea pipeline and stability technology, applied in the direction of pipeline laying and maintenance, pipe/pipe joints/pipe fittings, mechanical equipment, etc., can solve the problems of significant pressure load, overall instability, axial expansion of pipelines, etc. Overall buckling critical pressure, improved resistance to external load, effect of bending stress reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described below in conjunction with accompanying drawing and embodiment

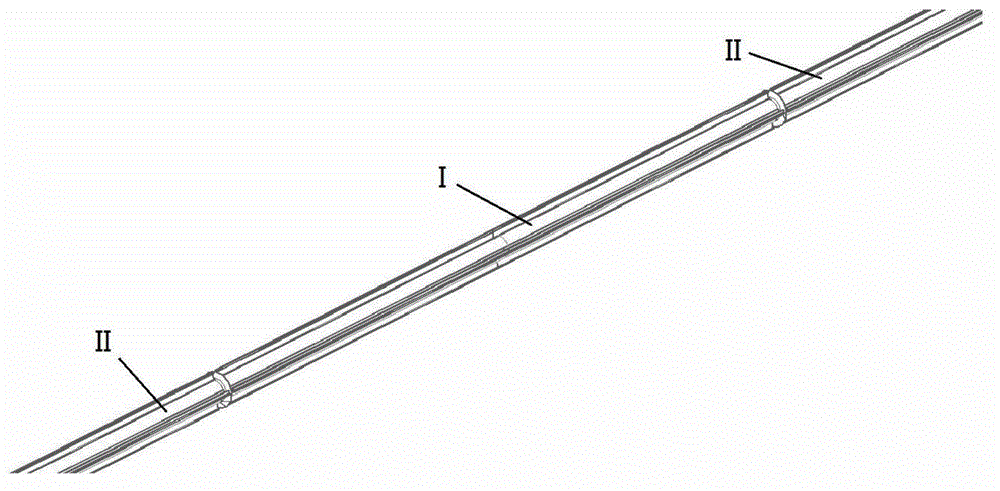

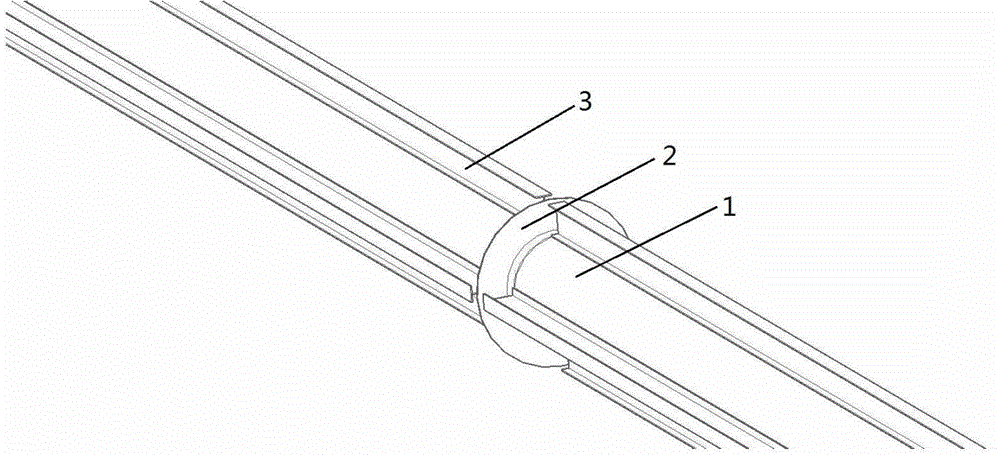

[0026] see figure 1 with figure 2 , the method for enhancing the stability of deepwater submarine pipeline of the present invention, comprises the following steps:

[0027] (1) Combined with the outer diameter and length of the reinforced pipe fitting (1), select narrow-wing H-shaped steel and narrow-wing T-shaped steel with the same width and size. The width of the H-shaped steel and T-shaped steel flanges is 15%~20% of the outer diameter of the pipe; the length of the H-shaped steel welded on the reinforced pipe fitting (1) along the axial direction is the difference between the length of the pipe fitting and twice the width of the T-shaped steel flange; The length of the H-shaped steel welded on the extension pipe section II in the axial direction is equal to that of the pipe fitting.

[0028] (2) Process the T-shaped steel into a hoop reinforcement, namely the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap