Tap changer and vacuum switching tube for such a tap changer

A technology of vacuum switch tube and tap changer, which is applied to electric switches, high-voltage/high-current switches, high-voltage air circuit breakers, etc., can solve the problems of high cost, large installation space, and high component cost, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

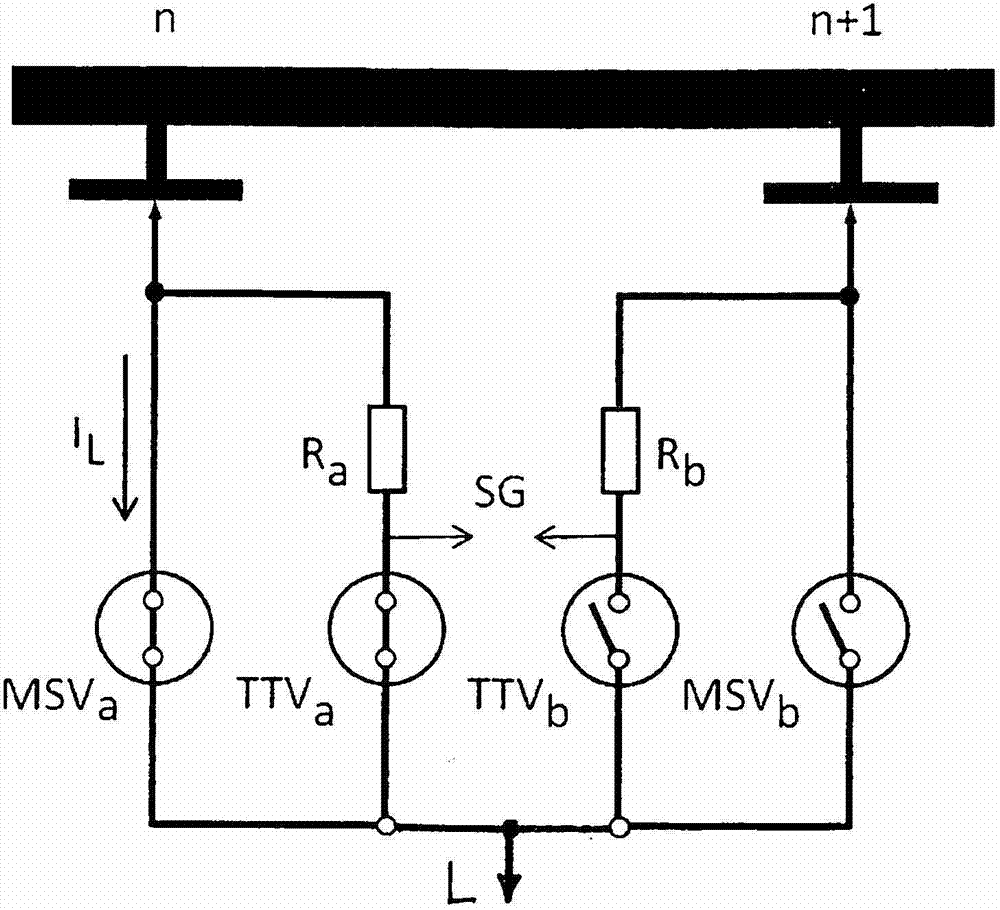

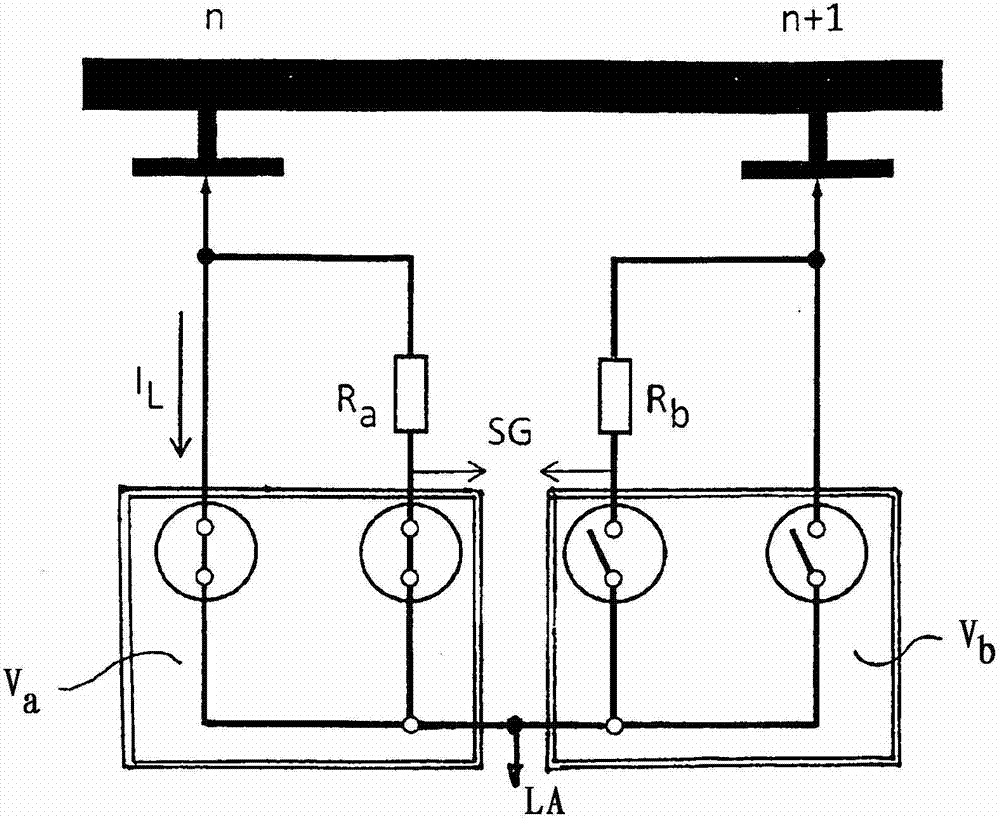

[0017] Figure 1 shows a known tap changer comprising a first load branch, a vacuum switch MSV used as the main contact a and the transition resistor R in parallel with it a and the vacuum switch tube TTV used as a resistive contact a in the first load branch. The second load branch is completely similar with the vacuum switch MSV b and another transition resistor R in parallel with it b and vacuum switch tube TTV b . The known tap changer has two vacuum switching units per load branch, thus a total of four vacuum switching units per phase.

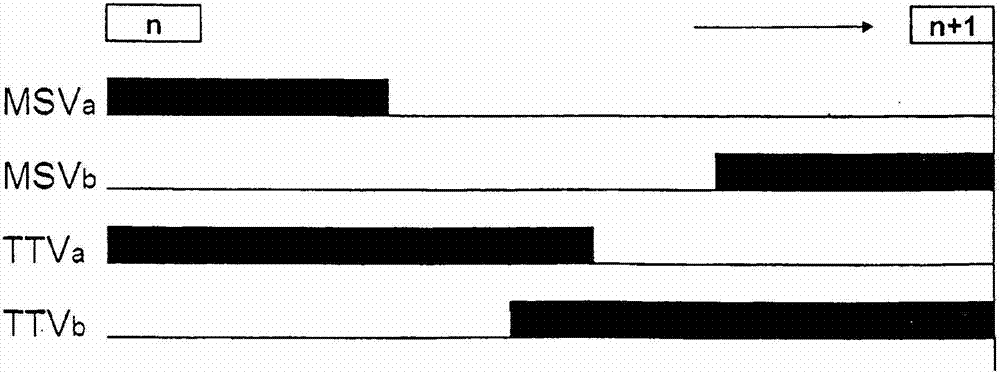

[0018] FIG. 2 shows the switching sequence of such a known tap changer when switching from winding tap n to winding tap n+1. The initial position of the tap n circuit connection corresponds to the position shown in FIG. 1 of the individual switching elements. Switching takes place in the following steps:

[0019] -MSV a disconnect

[0020] - TTV b closure

[0021] - TTV a disconnect

[0022] -MSV b Closed; end of switching. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com