Method for igniting high-pressure discharge lamps

A technology of high-pressure discharge lamps and igniters, which is applied in the use of gas discharge lamps, electric light sources, electrical components, etc., and can solve the problem that the ignition of high-pressure discharge lamps is not optimal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

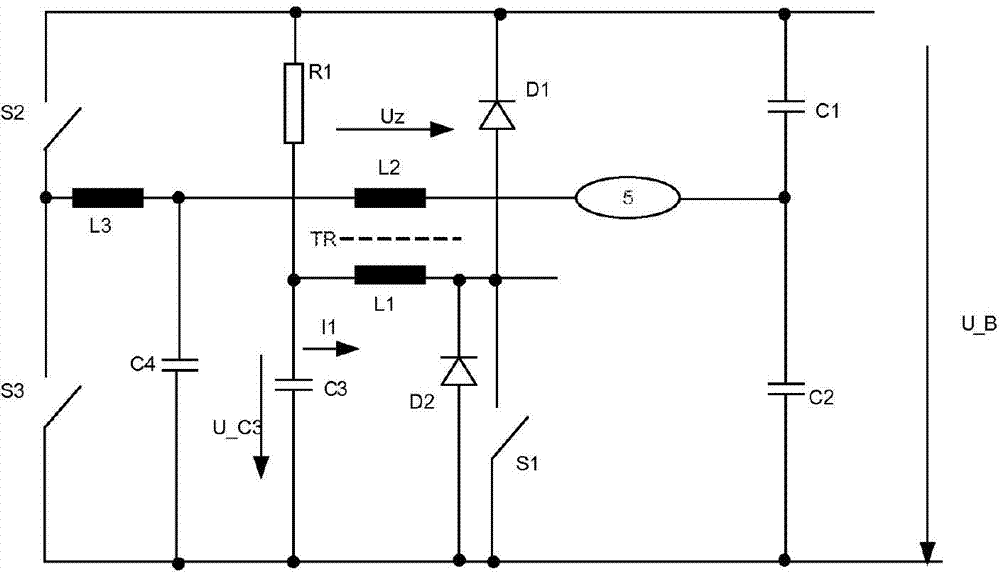

[0037] figure 1 A circuit arrangement known per se for operating a high-pressure discharge lamp is shown, said circuit arrangement having a half-bridge with series-connected half-bridge switches S2 and S3, at the center point of which a lamp choke is connected The series circuit of coil L3, secondary coil L2 of transformer TR and high-pressure discharge lamp 5 is ignited. The free end of the high-pressure discharge lamp 5 is connected to the connection point of the series circuit of two coupling capacitors C1 and C2. The half-bridge is connected in parallel with a series circuit of coupling capacitors. A supply voltage U_B (425 V in this exemplary embodiment) is applied to the parallel circuit. The ignition capacitor C3 and the ignition switch S1 are connected in series with the freewheeling diode D2 connected in parallel to the primary coil L1, which forms a primary circuit. The anode of the freewheeling diode and one terminal of the ignition capacitor C3 are connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com