Particle cleaning element for laundry washing and laundry washing method

A technology for cleaning elements and clothes washing, which is applied in the field of granular cleaning elements and clothes washing, which can solve the problems that nylon particles have limited ability to absorb dirt, cannot completely remove stains, and it is difficult to separate clothes and particles, so as to achieve decontamination ability and prevent Enhanced cross-color, cost saving, and good decontamination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Embodiment one solid particle

[0048] Figure 5 For the polymer solid particle 1 described in this embodiment, a large number of open cells 2 and channels 6 between cells are distributed on the surface of the particle, and the interior of the solid particle 1 is a solid structure, that is, the interior of the particle is a solid 5 inside the particle, The surface layer of the particles is a cell layer, which contains a large number of open cells 2, and the cells are surrounded by cell walls 3, and there are passages 6 connecting the cells, see Figure 6 .

[0049] In this embodiment, the surface layer of the solid particle 1 is a cell layer, and the inside of the particle is a solid structure. The volume of the pore layer on the surface of the particle is 0.01%-20% of the volume of the whole solid particle, so that the pollutants can be adsorbed on the surface or surface layer of the particle during the washing process of the particle and will not enter the center of...

Embodiment 2

[0056] Embodiment two particle cleaning element

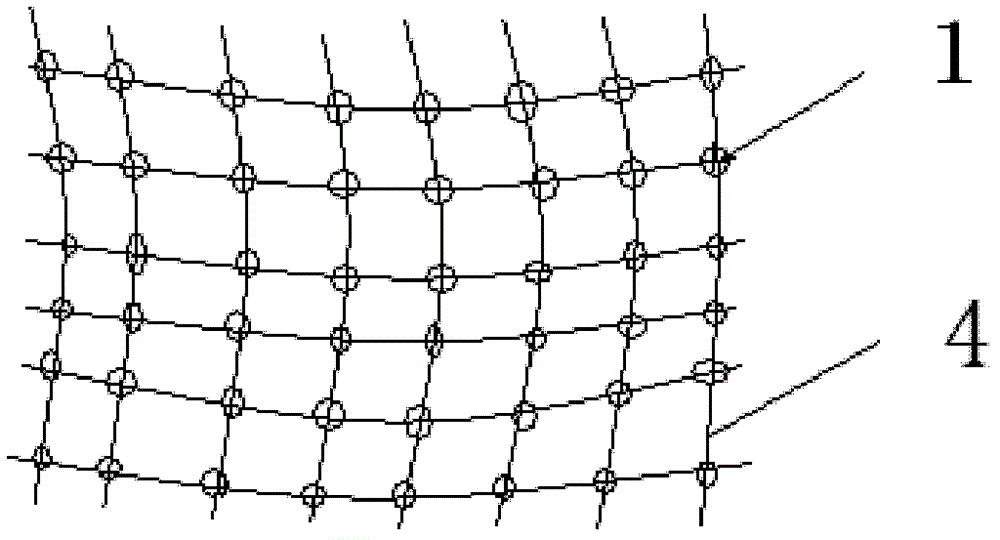

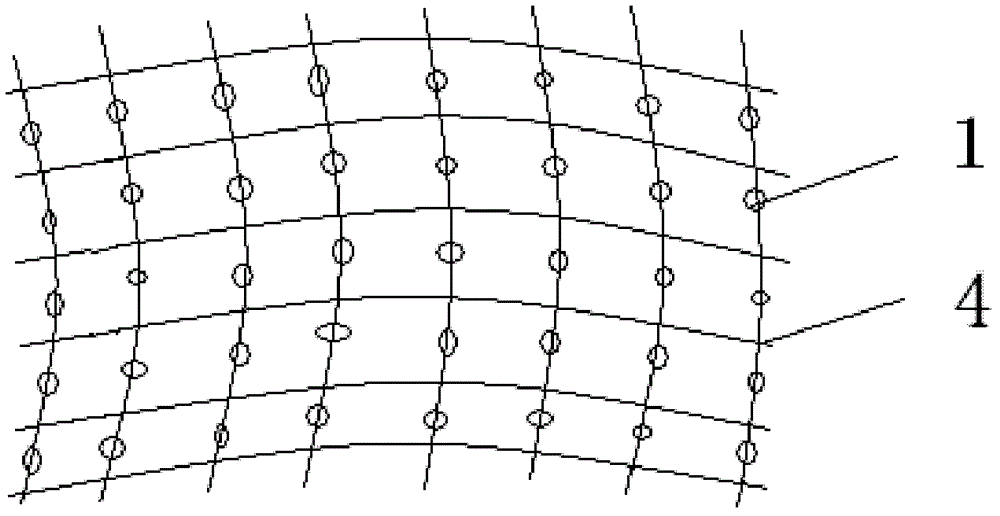

[0057] Such as figure 1 As shown, the granular cleaning element of the present invention comprises a plurality of solid cleaning particles 1 connected by flexible connectors 4 . Flexible connector 4 can adopt multiple embodiments, as, adopt the flexible connector of network structure (see figure 1 and figure 2 ), preferably a mesh structure with uniform mesh size. The solid particles 1 are fixed at the grid nodes of the mesh flexible connector (see figure 1 ) and / or slidably set between two adjacent nodes (see figure 2 ). The connection between the solid particles and the flexible connector can be any one of the prior art, as long as the solid particles can be connected to the flexible connector without falling off during the laundry washing process. Considering the stability of the connection, the present invention preferably adopts the method of perforating the solid particles through which the mesh wire passes to con...

Embodiment 3

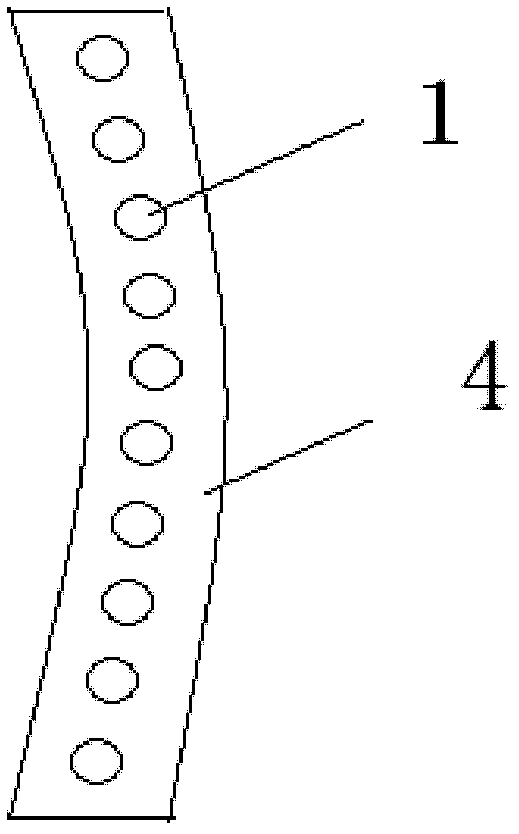

[0060] Example Three Particle Cleaning Elements

[0061] Such as Figure 3-1 , Figure 3-2 As shown, the flexible connector 4 in this embodiment is a strip-shaped flexible ribbon, and the solid particles 1 are fixed on the flexible ribbon in a tiled inlay or perforated manner.

[0062] The flexible connector 4 in this embodiment is made of carbon fiber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com