Clutch brake of press machine

A technology of brakes and presses, applied in the field of forging machinery, can solve the problems of not being able to meet the performance requirements of high-speed presses, large energy consumption, and large moment of inertia, etc., and achieve fast and reliable combination and separation, less energy consumption, and less transmission inertia Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

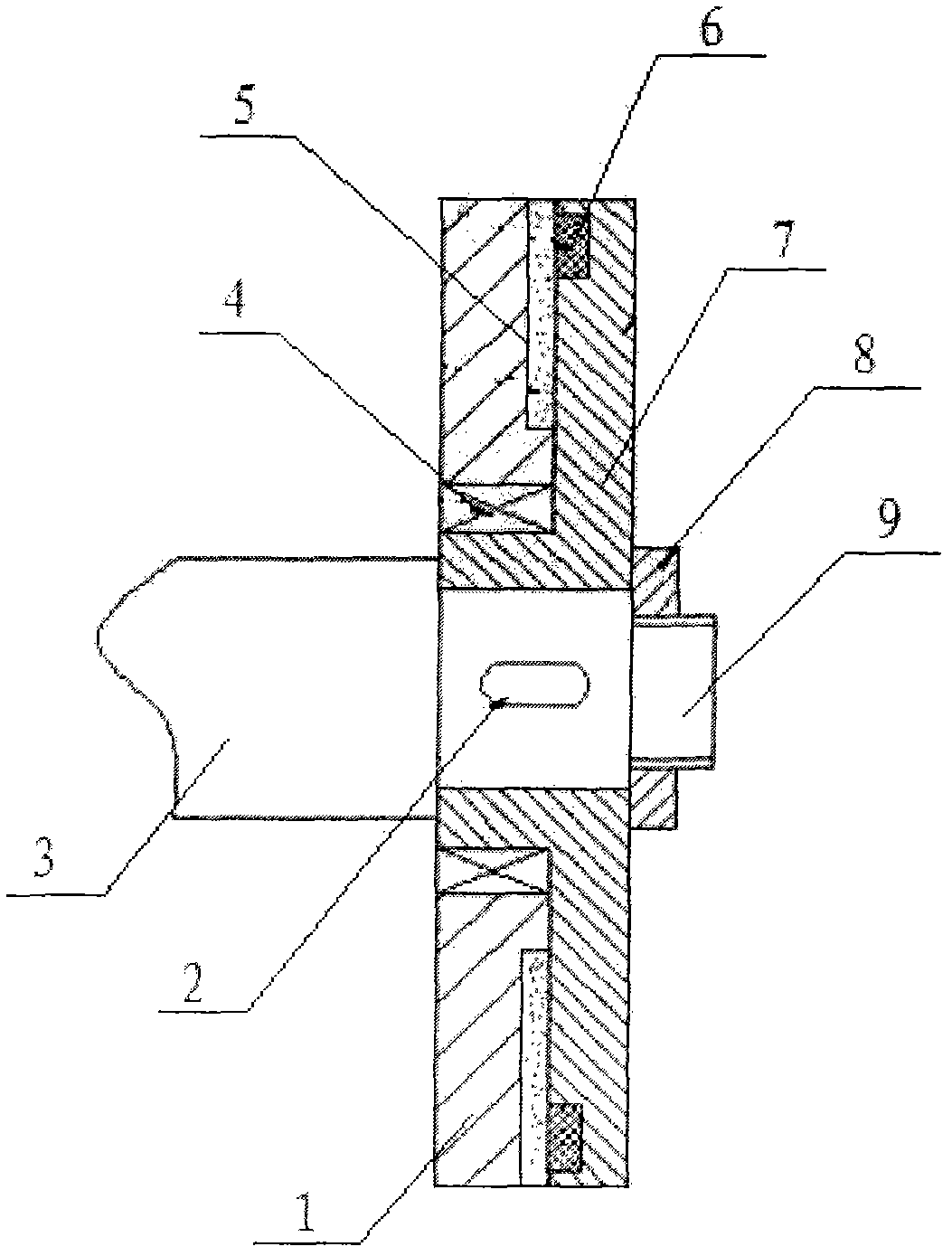

[0008] The clutch brake has a flywheel (1), and the multiplex bearing (4) is installed in the hollow shaft of the driving disc (7) through the flywheel (1), and the driving disc (7) is installed on the top of the crankshaft (3). ) to fix it on the crankshaft (3), install the coil (6) in the groove of the driving disc (7) and the flywheel (1), and install the conductive plate (9) at one end of the crankshaft (3) respectively, and the conductive plate ( 9) It is fixed on the crankshaft (3) by multi-position nuts (8).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com