Tension-free cable-laying crossing device

A tension-free and cable-free technology, applied in the direction of overhead lines/cable equipment, etc., can solve problems such as difficulty, time-consuming, and high construction costs, and achieve the effects of reduced production costs, low cost, and improved construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

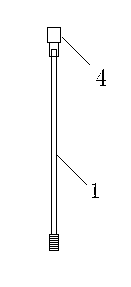

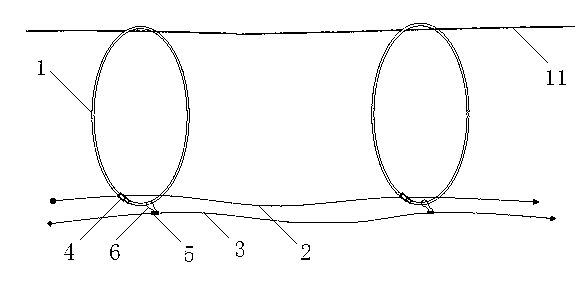

[0027] Such as figure 1 and figure 2 The shown tension-free cable release spanning device includes an elastic insulating rod 1, a cable guide rope 2 and a series traction rope 3. The material of the elastic insulating rod 1 is an insulating elastic glass fiber reinforced plastic composite material. metal joint 4, the elastic insulating rod 1 is butted through the metal joint 4 to form an elastic insulating ring, the cable guiding rope 2 passes through the elastic insulating ring, and the connecting ring 5 at intervals is fixed on the series traction rope 3, the The connecting ring 5 is fixedly connected with the elastic insulating ring through the hanging buckle 6 .

[0028] The above-mentioned elastic insulating rod 1 is made of insulating elastic fiberglass composite material.

[0029] Such as Figure 5 As shown, the buckle 6 is a gourd-shaped carabiner, including a hook 61 and an elastic push rod 63. The connecting end of the hook 61 and the elastic push rod 63 is provi...

Embodiment 2

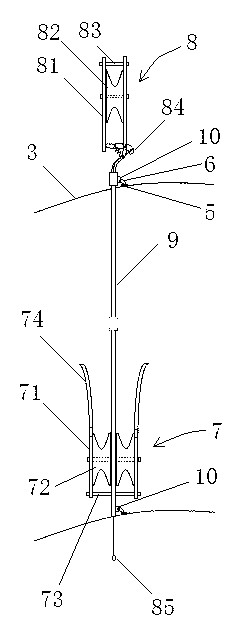

[0032] Such as image 3 The shown tension-free cable laying and spanning device includes an insulating pulley, a cable guiding rope 2 and a series traction rope 3, the cable guiding rope 2 is slidably connected to the guide pulley 7 of the insulating tackle, and the series pulling rope 3 is connected to the insulating pulley. The insulating connecting rod 9 of the pulley is connected; the insulating block also includes a traveling pulley 8 and a hollow insulating connecting rod 9, the upper end of the insulating connecting rod 9 is connected with the traveling pulley 8, and the lower part is connected with the guide pulley 7, and the upper end of the insulating connecting rod 9 , and the lower two ends are respectively provided with fixed rings 10, and the series traction rope 3 is connected with the fixed rings 10.

[0033] Such as image 3 As shown, the walking pulley 8 includes two vertical A splints 81 parallel to each other, and a first pulley 82 arranged between the A s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com