Turbulent-flow type dust-removing desulfurization system

A desulfurization system and turbulent flow technology, applied in the field of turbulent dust removal and desulfurization system, can solve the problems of short residence time of exhaust gas and unsatisfactory effect, and achieve the effect of small footprint, convenient maintenance and high desulfurization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

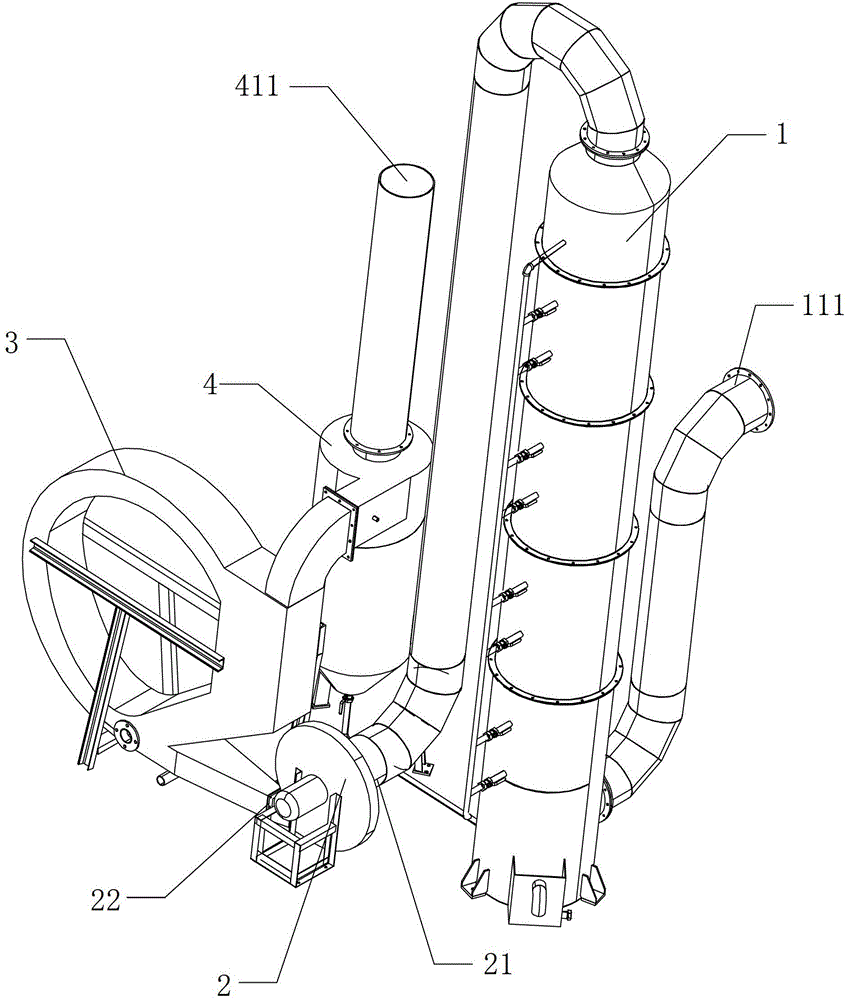

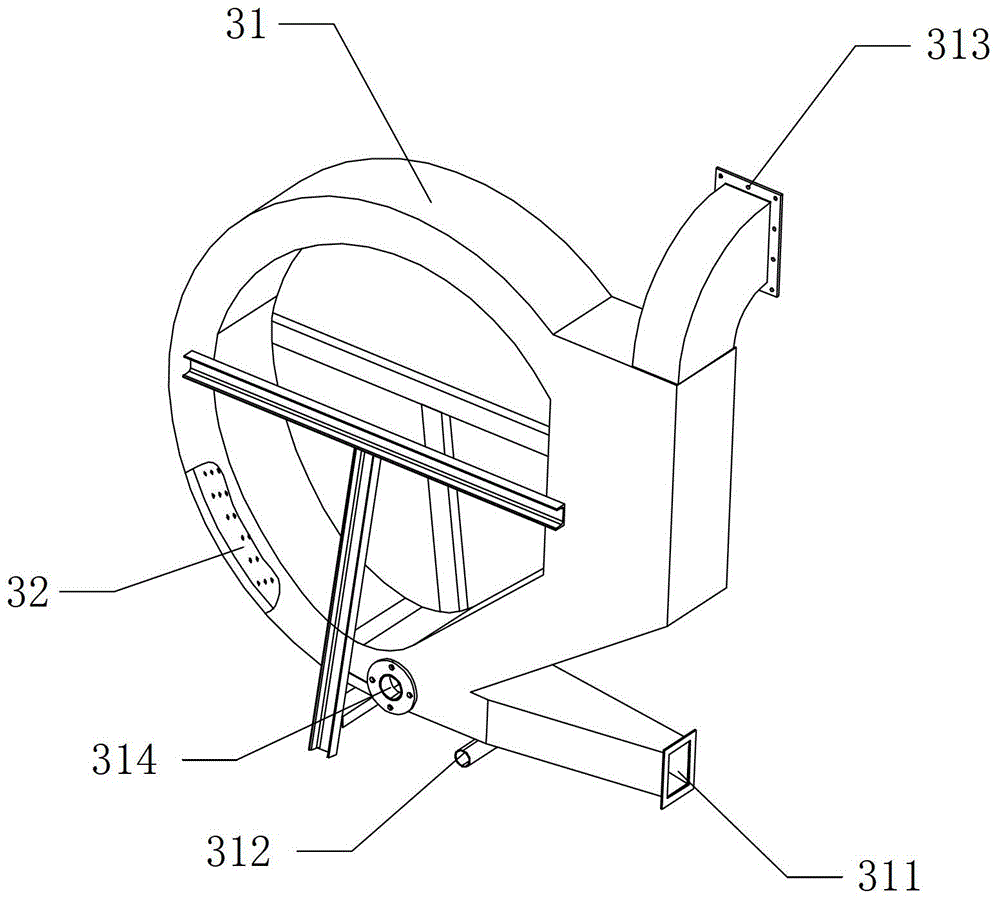

[0041] A turbulent flow dust removal and desulfurization system, such as figure 1 As shown, it is mainly composed of a turbulence tower 1, a fan 2, an annular cleaning device 3 and a water-soluble treatment device 4.

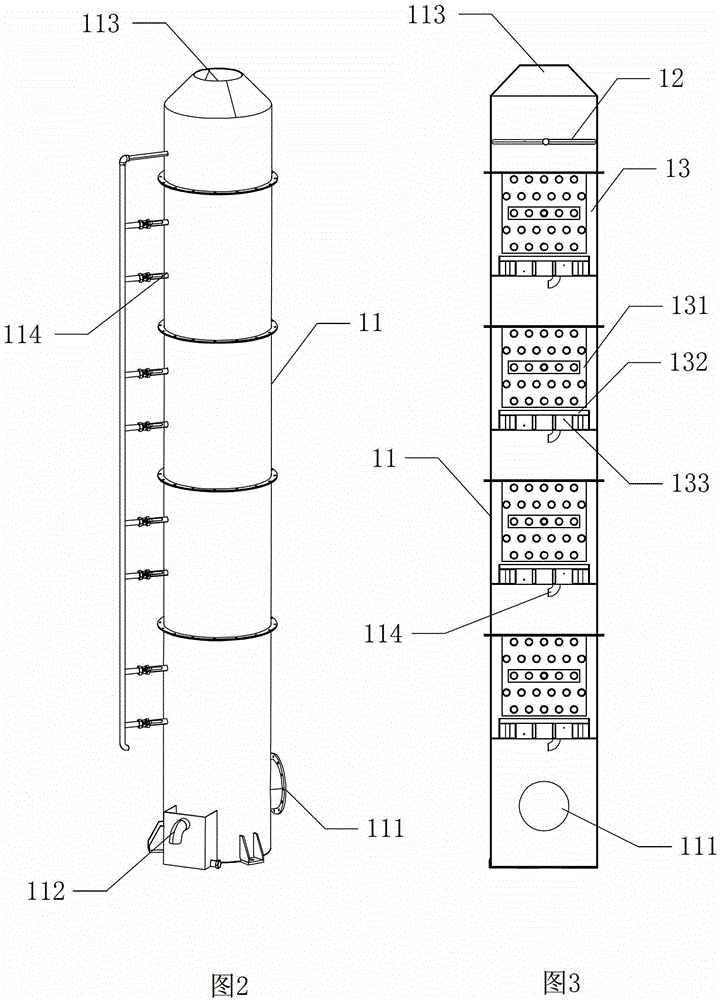

[0042] Above-mentioned turbulence tower 1 such as figure 2 and 3As shown, the above-mentioned turbulent flow tower 1 includes a closed and hollow cylindrical shell 11 , a spray ring pipe 12 fixed in the inner cavity of the cylindrical shell 11 and multi-layer independent turbulent flow guides 13 . The spray ring pipe 12 is located on the upper part of the inner cavity of the cylindrical housing 11 , and the multi-layer turbulent flow diversion body 13 is stacked and arranged below the spray ring pipe 12 . The spray ring pipe 12 communicates with the external water inlet pipe. Each turbulent flow guide body 13 includes a turbulent flow layer 131 and a flow guide layer 133 , and the turbulent flow layer 131 is located above the flow guide layer 133 . The turb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com