Processing method of bidirectional eccentric shaft

A processing method, eccentric shaft technology, applied in the field of outer circle processing of axial parts and outer circle of eccentric axial parts, it can solve the problem of not being able to guarantee the 180° reverse, not being able to accurately find the axis of the eccentric outer circle, and not being able to guarantee the eccentricity 180° of the outer circle is reversed to achieve the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

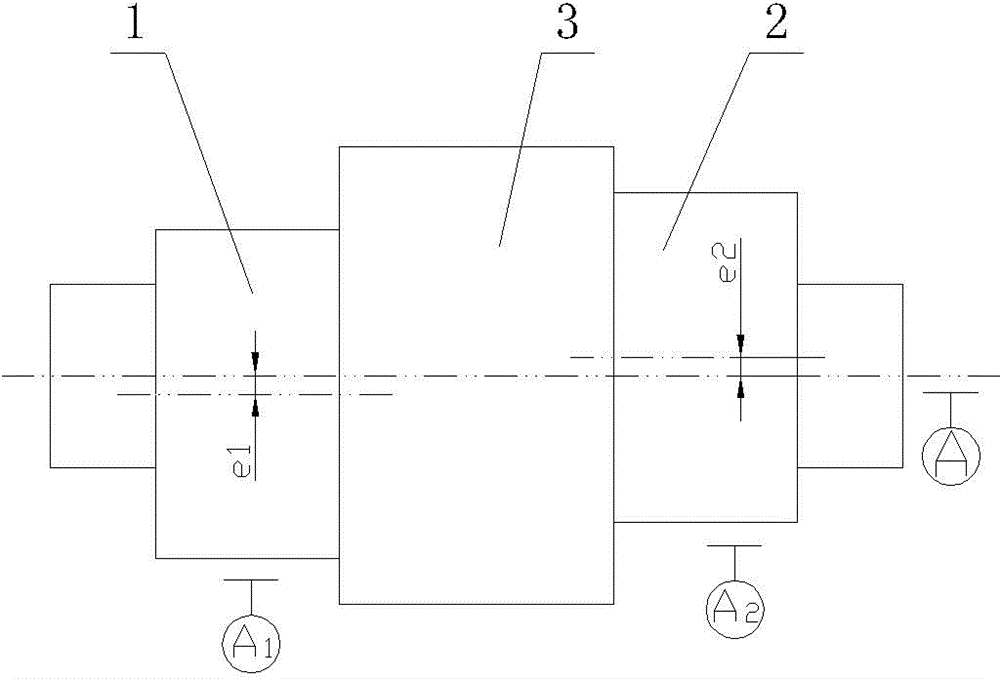

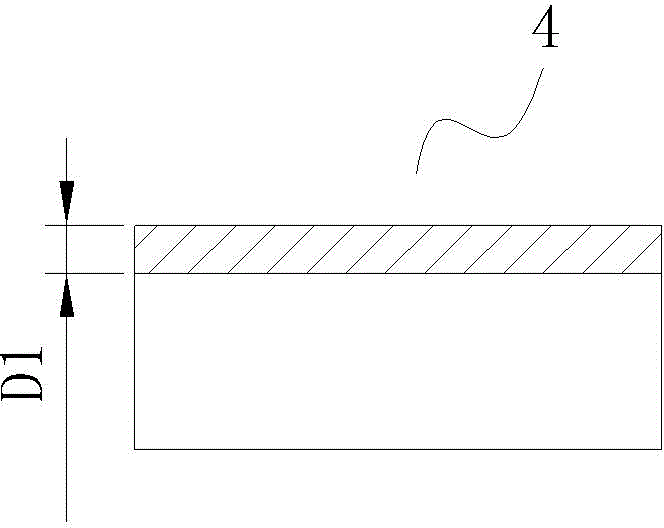

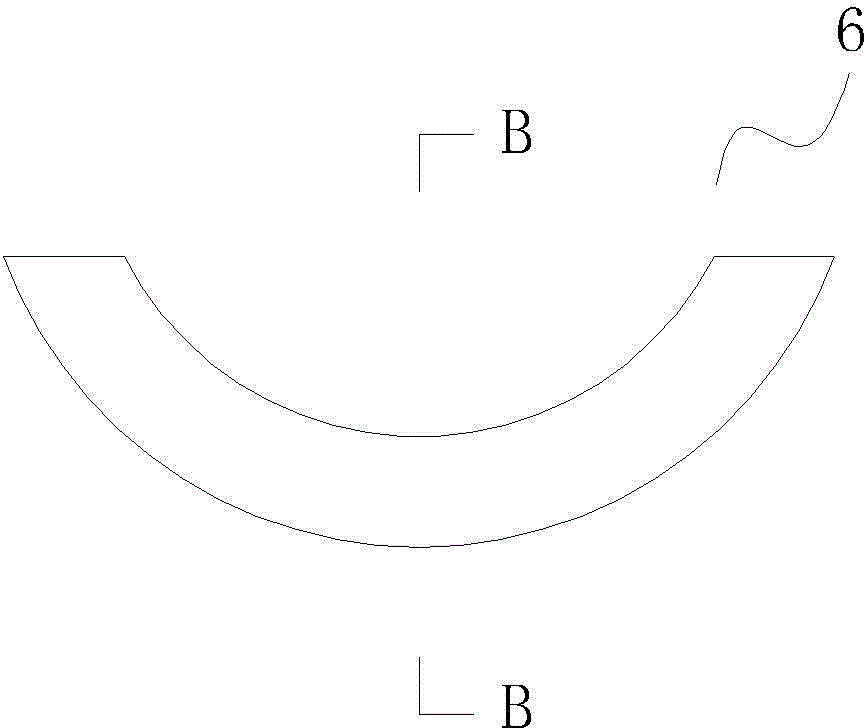

[0020] A method for processing a bidirectional eccentric shaft, which first turns the part blank, and adopts the turning processing method according to the accuracy requirements of the outer circle of the A reference, and processes the outer circle of the central axis 3 based on A to the requirements of the drawing. 1 、A 2 Leave a machining allowance of 2mm to 3mm for the outer circles of the first eccentric shaft 1 and the second eccentric shaft 2 respectively, and then finish machining the outer circle of the first eccentric shaft 1, see Image 6 , first place the first spacer 4 on the outer circle of the central axis 3 and then pre-clamp it with the three-jaw chuck 5. The first spacer 4 is an arc-shaped spacer, and its arc is the same as the outer arc of the central axis The degree is the same, and the thickness D1 of the first spacer 4=1.5e 1 ,See figure 2 with image 3 , and then use the dial indicator to calibrate the outer circle of the first eccentric shaft 1 to en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com