Microwave Dielectric Ceramics

A technology of microwave dielectric ceramics and conditions, applied in the direction of circuits, piezoelectric/electrostrictive/magnetostrictive devices, electrical components, etc., can solve the problems of high price and limited commercial application, and achieve low price and good microwave dielectric The effect of electrical performance and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The invention discloses a preparation method of microwave dielectric ceramics, which comprises the following steps:

[0021] (A) Put CaCO 3 , TiO 2 , La 2 O 3 , Sm 2 O 3 And Al 2 O 3 Ball milling, calcining after drying to obtain a ceramic body;

[0022] (B) The ceramic body is crushed and ball milled to obtain a powder;

[0023] (C) granulating the powder, dry pressing and forming to obtain a compressed tablet;

[0024] (D) Sintering the pressed sheet at 1350-1500°C to obtain microwave dielectric ceramics, the chemical composition of which is expressed by formula (I);

[0025] aCaCO 3 -bTiO 2 -cLa 2 O 3 -dSm 2 O 3 -eAl 2 O 3 (I);

[0026] 34mol%≤a≤42mol%, 36mol%≤b≤44mol%, 0mol%≤c≤16mol%, 0mol%≤d≤16mol%, 6mol%≤e≤14mol%; a+c+d=50mol%, b +e=50mol%.

[0027] In the present invention, the CaCO 3 , TiO 2 , La 2 O 3 , Sm 2 O 3 And Al 2 O 3 Ball milling, calcination after drying to obtain a ceramic body. The present invention has no special restrictions on ball milling, and it is prefer...

Embodiment 1

[0035] Take 0.41mol of CaCO 3 , 0.41mol TiO 2 , 0.09mol Sm 2 O 3 , 0.09mol of Al 2 O 3 , Calculate the quality of each analytically pure raw material required; put the accurately weighed raw materials into the ball mill tank; add alcohol and ZrO 2 Grinding ball, raw material, ZrO 2 The mass ratio of the grinding ball to the alcohol is 1:2:1.5; the ball is milled for 24 hours, mixed evenly, and the material is discharged, and it is dried at 100~120℃; then it is calcined at 1200℃ for 2 hours to synthesize the ceramic body. The above-mentioned ceramic body is crushed with a mortar and passed through a 40-mesh sieve, and then poured into a ball milling tank for secondary ball milling for 24 hours; the ratio of material: ball: alcohol remains unchanged; the material is discharged and the slurry is dried after drying. Mesh sieve to obtain powder.

[0036] Add 10wt% polyvinyl alcohol solution to the obtained powder for granulation and pass through a 40-mesh sieve, the concentration of th...

Embodiment 2~28

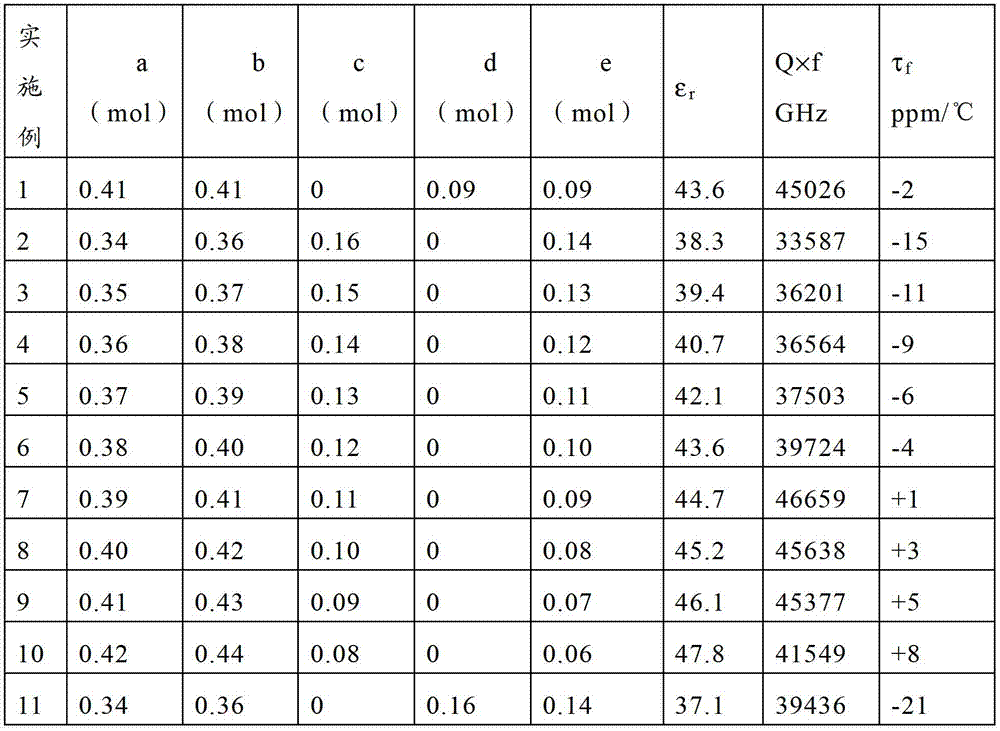

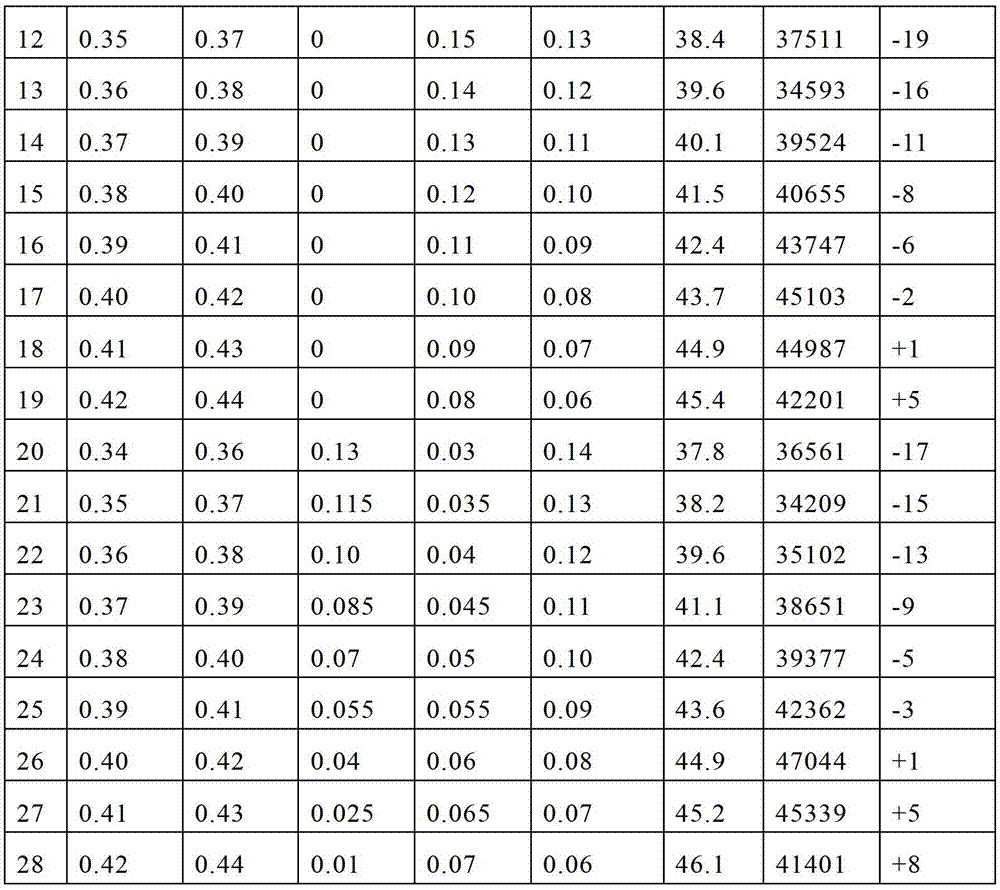

[0039] Referring to the method described in Example 1, according to different raw material ratios, microwave dielectric ceramics were prepared, and the raw material ratio and microwave dielectric performance parameters are shown in Table 1.

[0040] Table 1 Microwave dielectric performance parameters of microwave dielectric ceramics obtained in each embodiment

[0041]

[0042]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com