Hidden type bridge tower lamp and lamp bracket thereof

A lamp bracket and concealed technology, which is applied in the field of lighting, can solve the problems that the bridge tower cannot achieve the expected shape design effect, the installation hole is difficult to drill, and the overall aesthetic appearance of the bridge tower is damaged.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

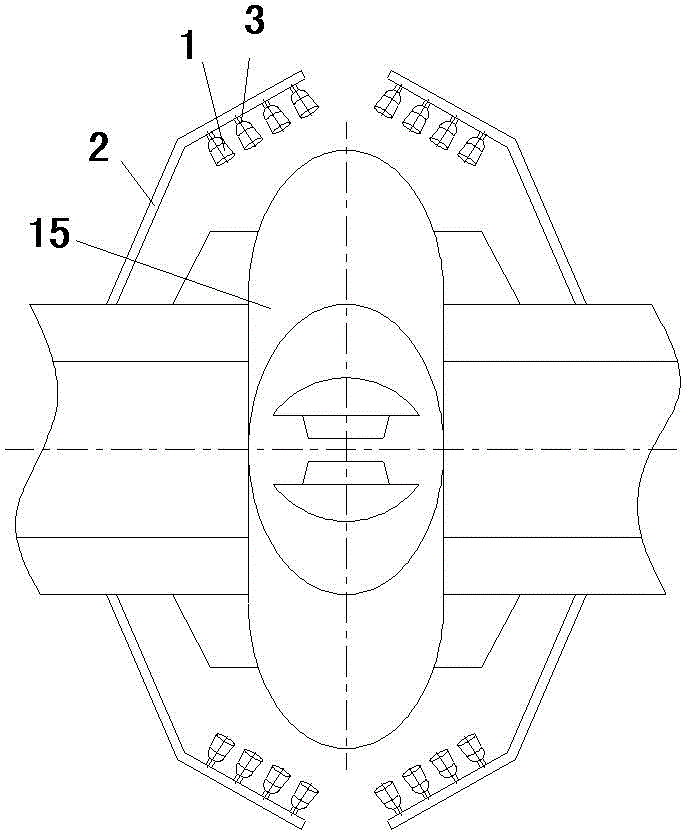

[0029] Such as figure 1 As shown, it is a schematic structural diagram of the first embodiment of the concealed bridge tower 15 lamp of the present invention. The concealed bridge tower 15 lamp of this embodiment includes a projection lamp 1 for projecting light to the bridge tower 15 and at least one lamp holder. The lamp holder 2 of the lamp holder is provided with a lamp holder 3, and the projector lamp 1 is installed on the lamp holder 3, the concealed bridge tower 15 lamps of this embodiment include two sets of lamp brackets respectively arranged on both sides of the main tower of the bridge, and each set of lamp brackets includes two lamps that cooperate with each other and project lights to one side of the main tower of the bridge Bracket. Of course, the number of lamp holders can be set according to actual design needs, and will not be repeated.

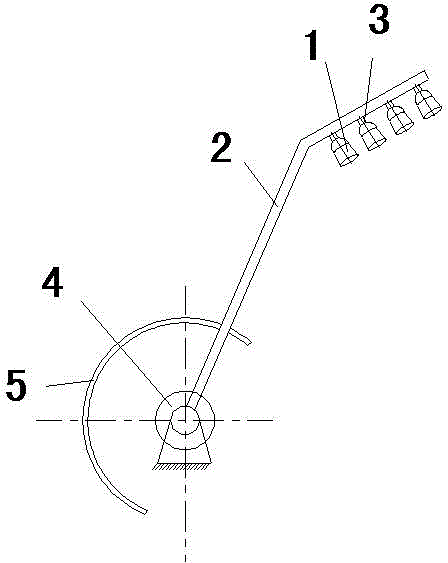

[0030] The lamp bracket of this embodiment includes a lamp holder 2 hingedly installed under the belly of the bridge beam and...

no. 2 example

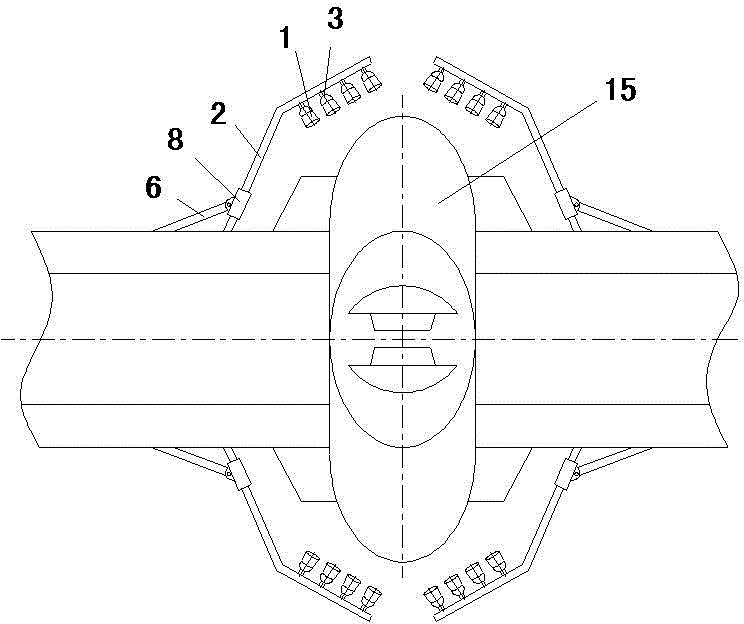

[0034] Such as image 3 As shown, it is a schematic structural diagram of the second embodiment of the concealed tower lamp of the present invention. The concealed bridge tower lamp of this embodiment includes a projector lamp 1 for projecting light to the bridge tower 15 and at least one lamp holder. The lamp holder 2 of the lamp holder is provided with a lamp holder 3, and the projector lamp 1 is installed on the lamp holder 3. on. The concealed bridge tower 15 lamps of this embodiment include two groups of lamp brackets respectively arranged on both sides of the main tower of the bridge, and each group of lamp brackets includes two lamp brackets that cooperate with each other and project lights to one side of the main tower of the bridge. Of course, the number of light fixtures can be set according to actual design needs, and will not be repeated.

[0035] The lamp bracket includes a lamp bracket 2 hingedly installed on the underside of the bridge wing / under the belly of the ...

no. 3 example

[0040] Such as Figure 5 As shown, it is a schematic structural diagram of the third embodiment of the concealed bridge tower lamp of the present invention. The concealed bridge tower lamp of this embodiment includes a projector lamp 1 for projecting light to the bridge tower 15 and at least one lamp holder. The lamp holder 2 of the lamp holder is provided with a lamp holder 3, and the projector lamp 1 is installed on the lamp holder 3. on. The concealed bridge tower 15 lamps of this embodiment include two groups of lamp brackets respectively arranged on both sides of the main tower of the bridge, and each group of lamp brackets includes two lamp brackets that cooperate with each other and project lights to one side of the main tower of the bridge. Of course, the number of light fixtures can be set according to actual design needs, and will not be repeated.

[0041] The lamp holder of this embodiment includes a lamp holder 2 hingedly installed under the belly of the bridge beam ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com