Dry rigid connection prefabricated assembly integral frame structure and construction method thereof

A rigid connection and prefabricated assembly technology, applied in the direction of building structure, construction, etc., can solve the problems of difficult collision avoidance of steel bars, unstable connection of post-cast concrete, etc., and achieve the effect of improving installation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

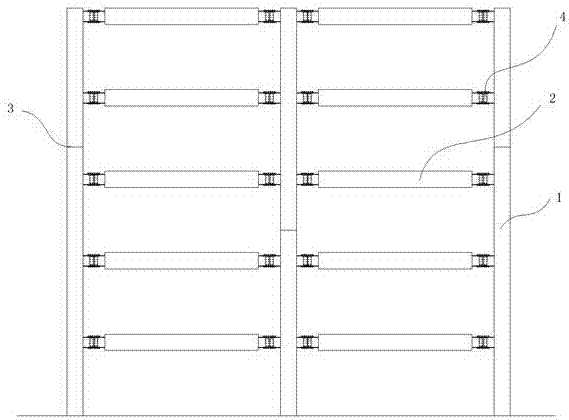

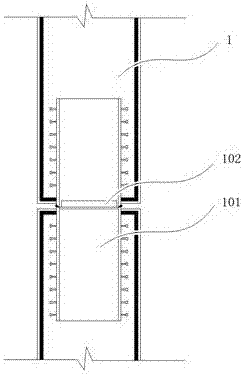

[0059] Such as figure 1 Shown is a schematic diagram of a frame structure of Embodiment 1 of the present invention. The first floor of the prefabricated concrete column 1 is not disconnected, and the longitudinal connection nodes 3 are set at the height of 1.3m on each floor above the second floor. The longitudinal connecting node 3 is formed by groove welding the column connecting steel 101 protruding from two adjacent concrete prefabricated columns 1 up and down. Concrete prefabricated column 1 is prefabricated across floors, and can also be prefabricated at full height if site conditions permit.

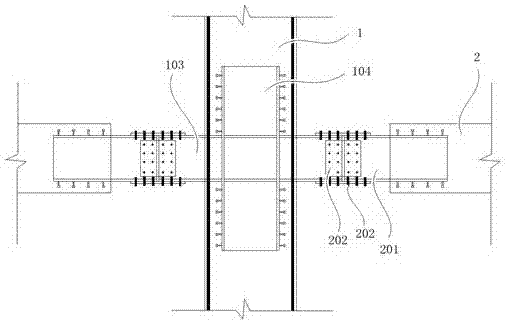

[0060] A number of steel corbels 103 are provided on the side of the prefabricated concrete column 1, and the number of steel corbels 103 arranged on the sides, vertices, and interiors of the frame structure is different. According to the actual needs of the connection nodes, the number of steel corbels 103 The number can be 2 to 4, such as Figure 4 The number of steel corbels...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com