Convertible welding and slicing combined processing system for flat and folding masks

A combined processing and mask technology, applied in the field of convertible welding and punching combined processing systems, can solve the problems of inability to switch between different types of masks, poor versatility of the punching machine, and inflexible use, so as to achieve unaffected structural performance and strong flexibility. The effect of high performance and practicability, and strong mechanical versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

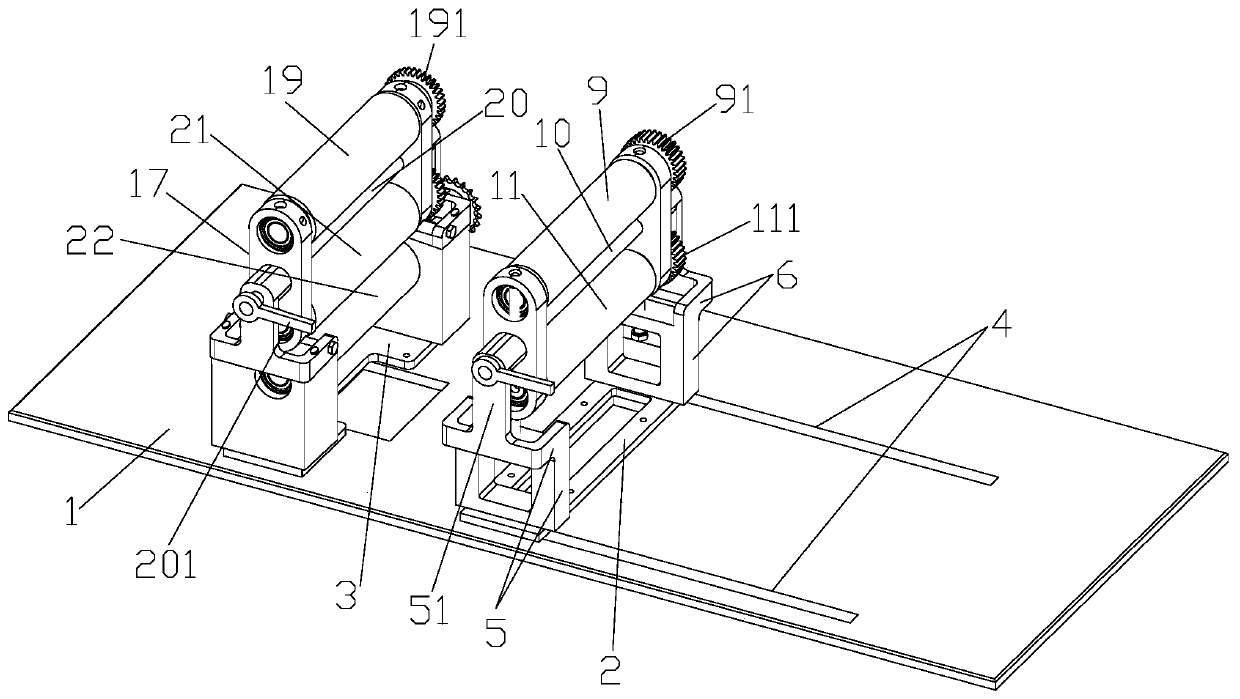

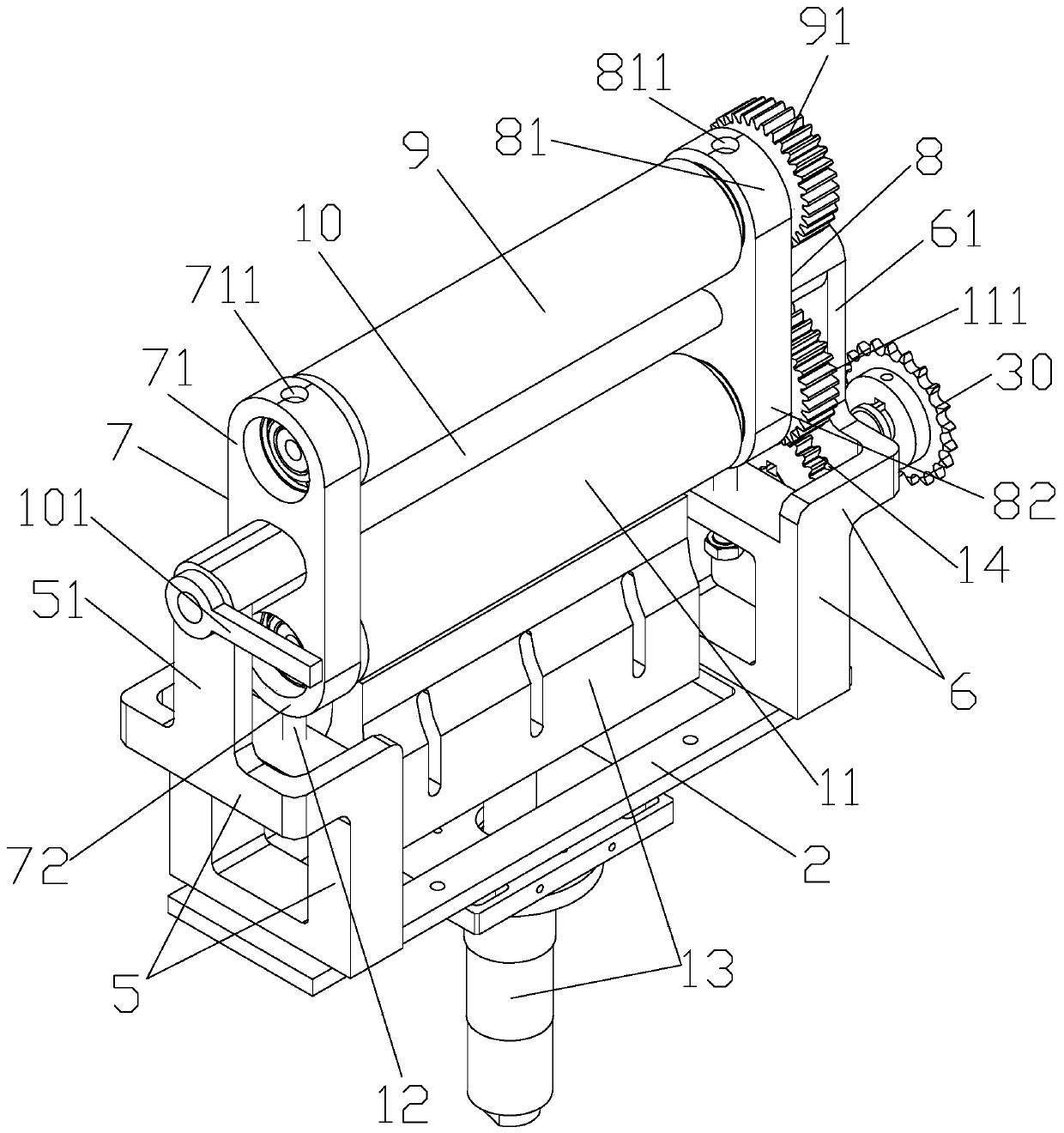

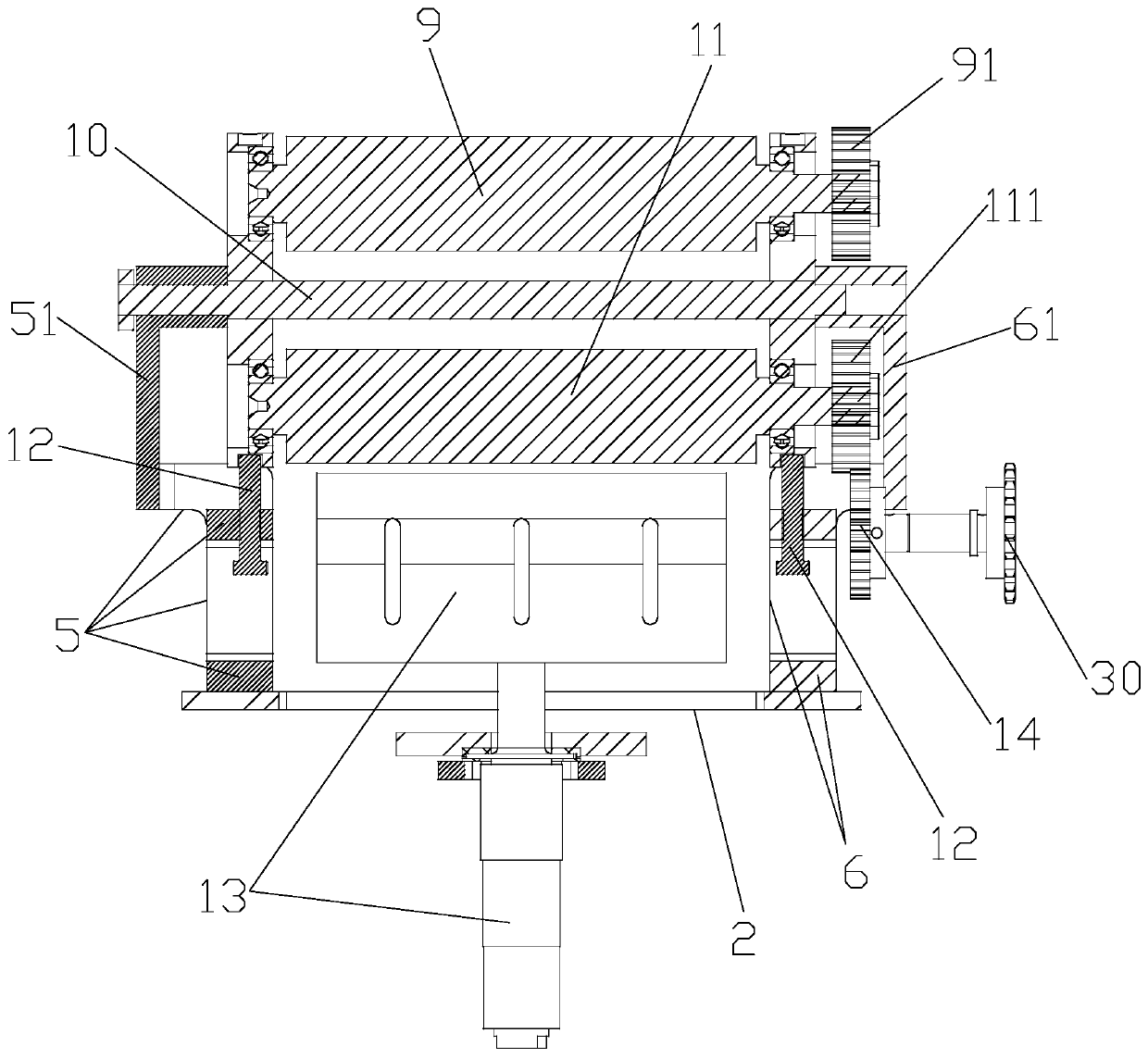

[0037] Such as Figure 1 to Figure 7 As shown, a convertible welding combined processing system for flat and folded masks, including a base plate 1, on which an ultrasonic welding device and a punching processing device are arranged, the ultrasonic welding device includes a welding support seat, and the top of the welding support seat rotates The rotating shaft A10 is installed, the rotating arm A7 and the rotating arm B8 are fixed on both sides of the rotating shaft A10, and the flat mask roller welding mold 9 and the folding mask roller welding mold 11 are installed in rotation between the rotating arm A7 and the rotating arm B8, and the flat mask roller Welding mold 9, folding mask cylinder welding mold 11 are positioned at both sides of rotating shaft A10 (as figure 2 As shown, the flat mask cylinder welding mold 9 and the folding mask cylinder welding mold 11 are respectively symmetrically located on the upper and lower sides of the rotation axis A10), the central shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com