A structural component strength testing device

A technology for strength detection and structural components, applied in the direction of measuring devices, strength characteristics, instruments, etc., can solve the problems of wrong calculation results, the rebound value data does not correspond to the detection angle, affecting the accuracy of the strength of the detected concrete components, etc. The effect of small working lengths

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

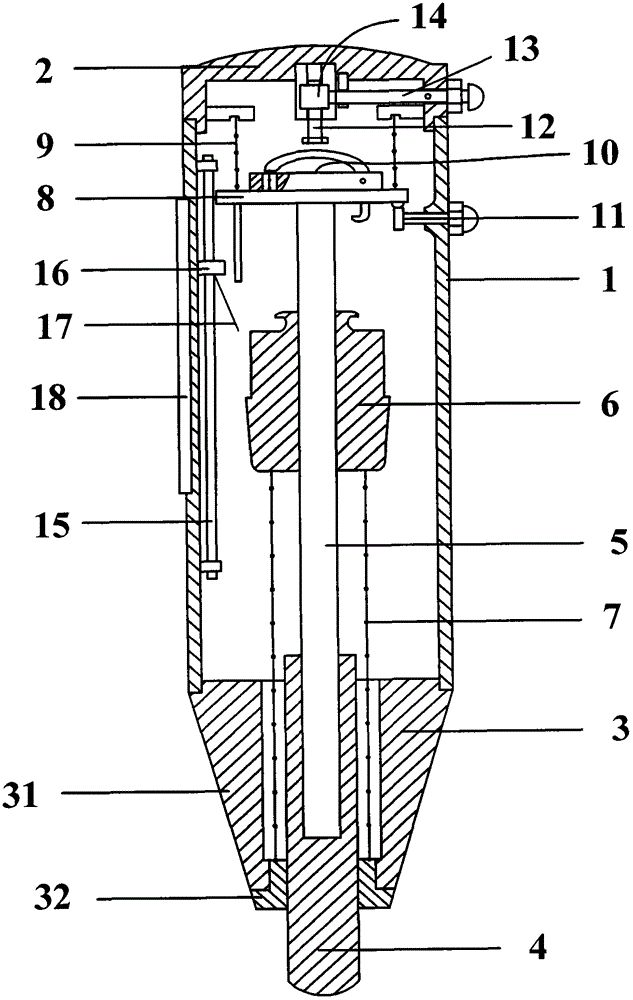

[0045] In order to improve the accuracy of detecting the strength of structural members, the present invention provides a device for detecting the strength of structural members. Stretch the length to overcome the impact of the gravitational potential energy of the hammer, so that the energy of the structural member when it is bounced upward or downward is consistent with that of the horizontal bounce, so there is no need to classify and record the rebound value of different detection angles. The probability of errors in data collection and calculation processes is reduced, thereby improving the accuracy of detecting the strength of structural members.

[0046] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

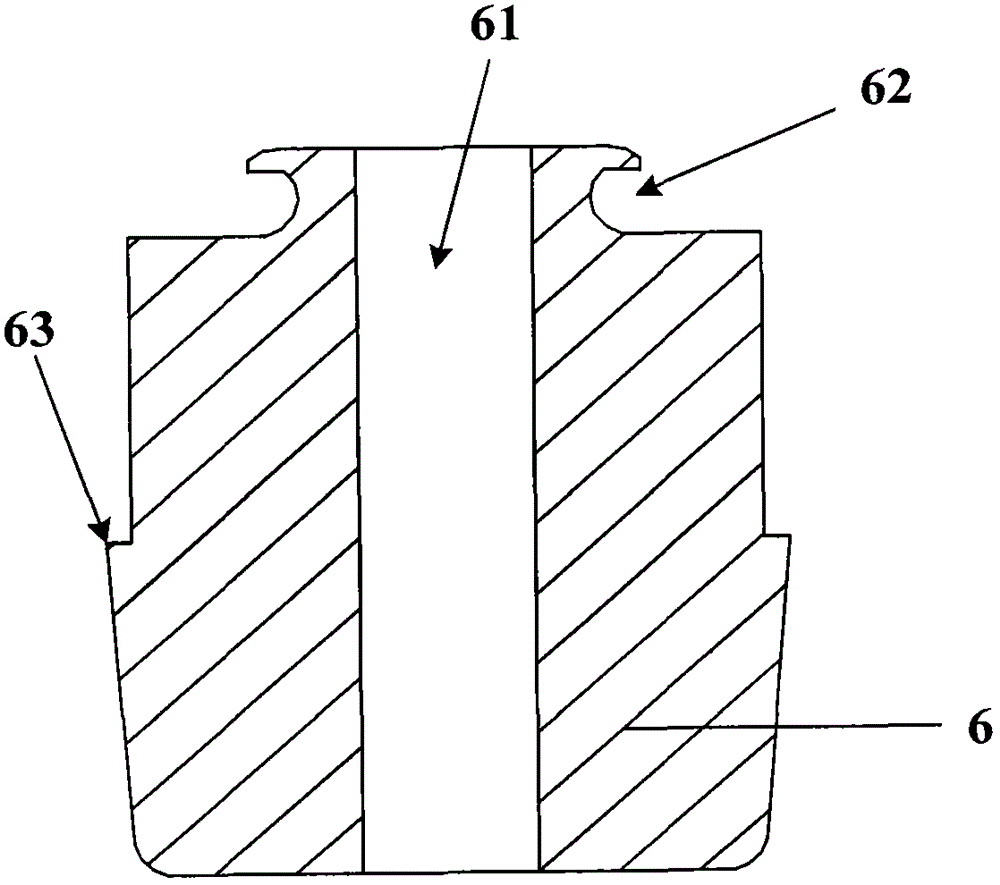

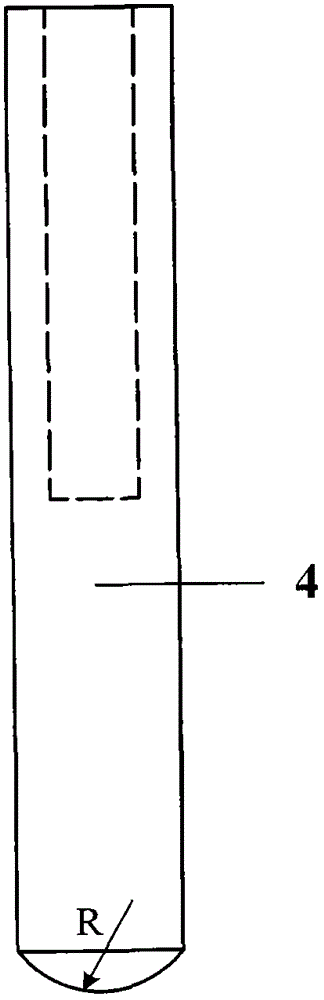

[0047] Such as figure 1 As shown, the structural member strength detection device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com