Method and device for monitoring dirtiness of insulator

A monitoring device and insulator technology, applied in measurement devices, material analysis by optical means, instruments, etc., can solve the problems of inability to directly measure the salt density of charged insulators, high cost of optical sensing components, and achieve low cost, accurate measurement, adaptable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

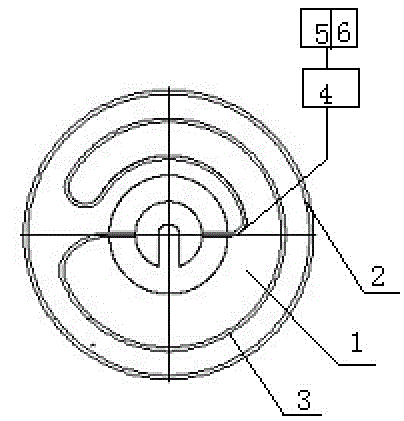

[0018] Embodiment 1, its method is to arrange optical fiber on the insulator, connect signal output and signal receiving ratio measuring device on the optical fiber, and throw away the outer cladding of optical fiber, utilize the light intensity in the optical fiber that can influence the light intensity in the optical fiber to measure stickiness when utilizing dirt sticking to the optical fiber surface The degree of pollution of the insulation covering the insulator. A wireless transmitting device is connected to the signal receiving and measuring device, and when the light intensity detected by the signal receiving and measuring device is lower than a specified value, the wireless transmitting device sends a signal to alarm to realize online monitoring.

[0019] The preferred solution is to open a groove on the insulator, and the optical fiber is glued in the groove, and at the same time, one or several insulators with optical fiber are connected to the insulator string of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com