Automatic testing device for contact resistor made of electrical contact material

An automatic test device and a technology for electrical contact materials, which are used in measuring devices, measuring resistance/reactance/impedance, measuring electrical variables, etc., to achieve the effects of convenient operation, high efficiency and accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

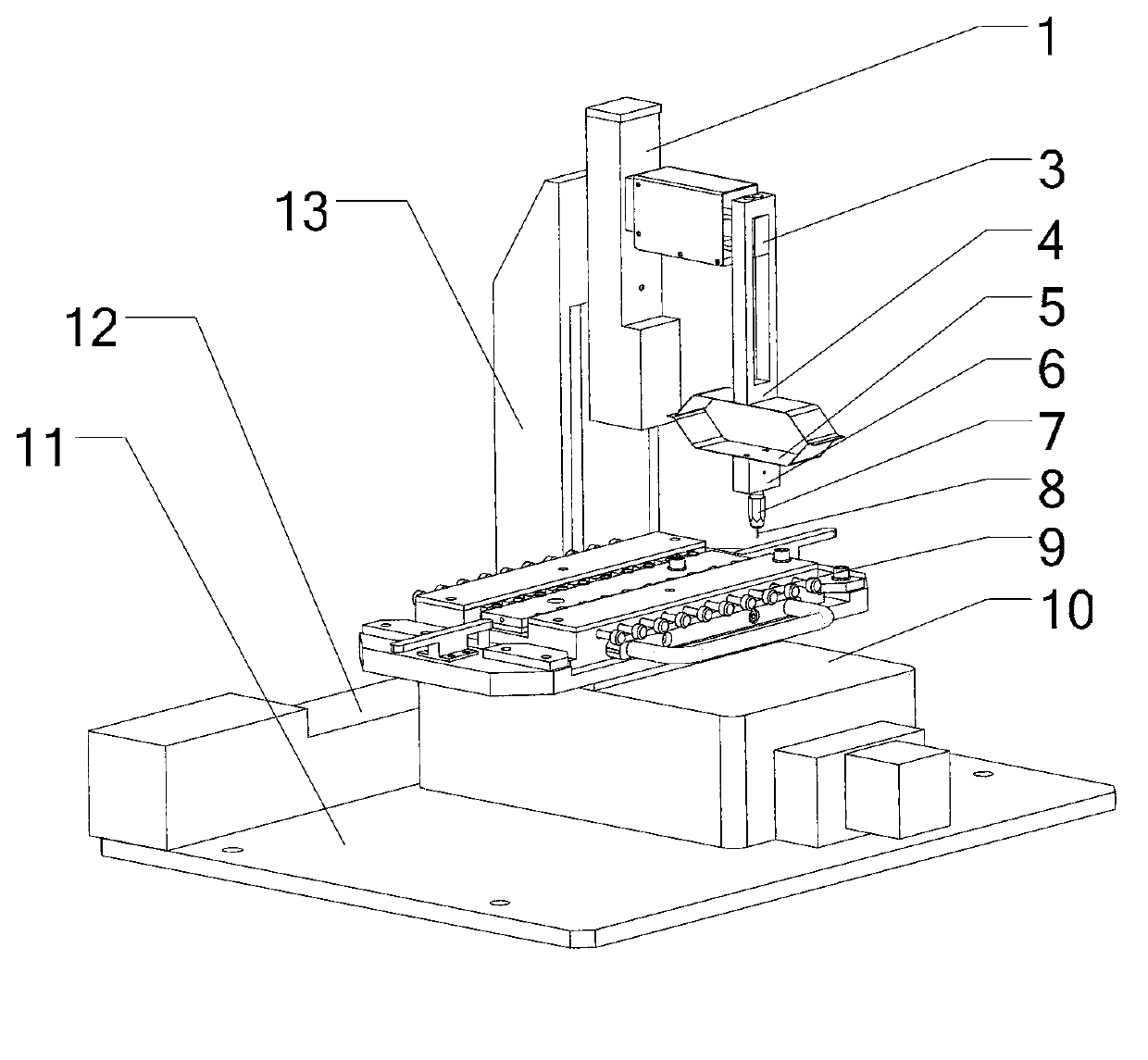

[0009] Specific implementation mode one: combine figure 1 Describe this embodiment mode, the electric contact material contact resistance automatic testing device described in this embodiment mode, it comprises vertical slide table 1, control component 2, pressure sensor 3, pressure sensor connector 4, elastic element 5, probe fixture connection Part 6, probe clamp 7, probe 8, multi-contact clamp body 9, longitudinal slide 10, machine base 11, transverse slide 12 and transverse and longitudinal slide connector 13; the elastic element 5 adopts hexagonal Ring-shaped elastic element; the longitudinal slide 10 and the transverse slide 12 are all arranged on the upper surface of the base 11; the transverse slide 12 is arranged along a side of the base 11; the longitudinal slide 10 and the transverse slide The table 12 is arranged vertically; the vertical slide table 10 is connected with the horizontal slide table 12 through the horizontal slide table connector 13; the vertical slid...

specific Embodiment approach 2

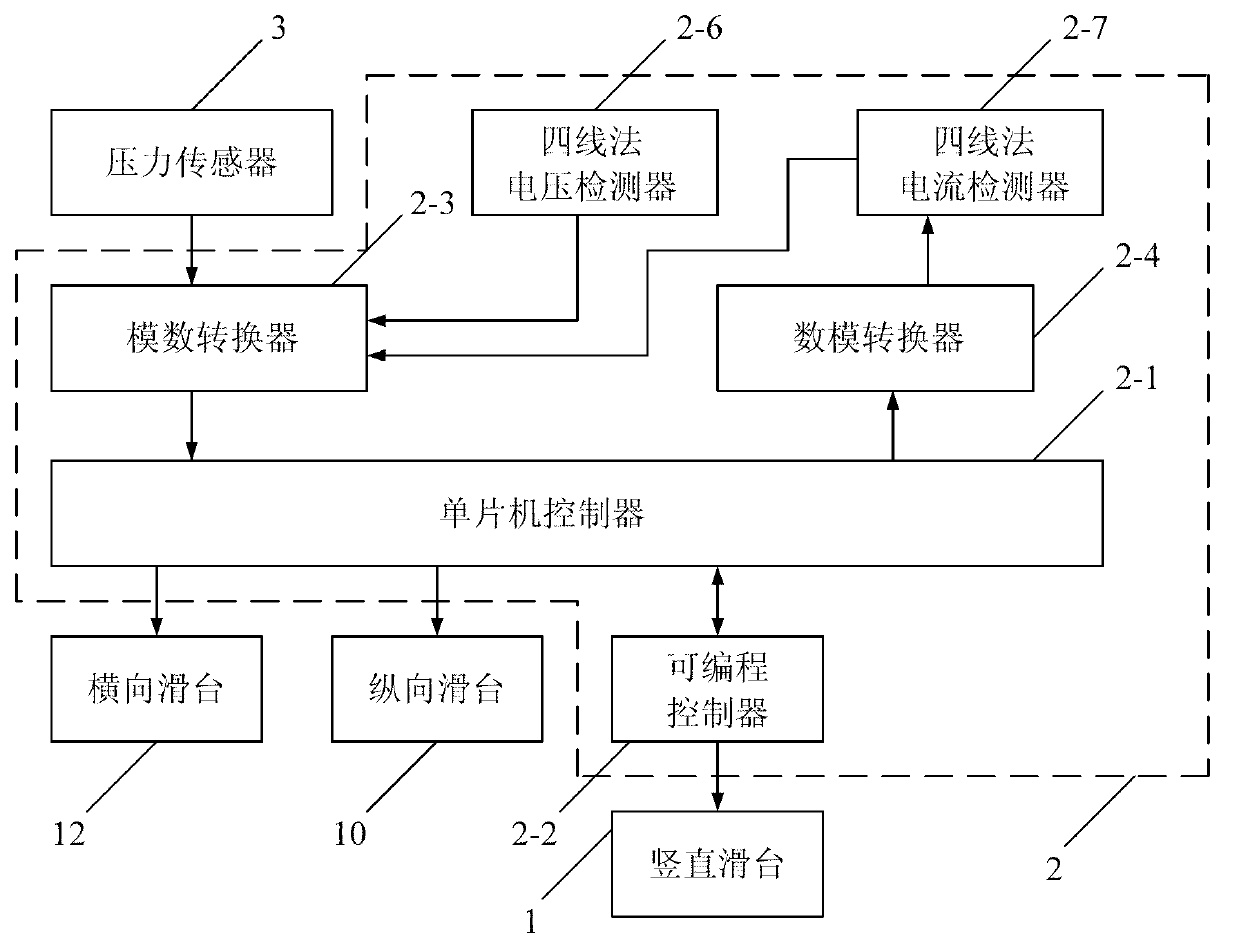

[0010] Specific implementation mode two: combination figure 2 Describe this embodiment, the difference between this embodiment and the specific embodiment is that the control assembly 2 includes a single-chip controller 2-1, a programmable controller 2-2, an analog-to-digital converter 2-3, and a digital-to-analog converter 2-4 , four-wire method voltage detector 2-5 and four-wire method current detector 2-6; the analog-to-digital conversion data input end of the single-chip controller 2-1 and the analog-to-digital conversion data output of the analog-to-digital converter 2-3 The pressure sensing data signal input end of the analog-to-digital converter 2-3 is the pressure sensing signal input end of the control assembly 2; the voltage detection data signal input end of the analog-to-digital converter 2-3 and the current detection data signal The input terminal is respectively connected to the voltage detection data signal output end of the four-wire method voltage detector 2-...

specific Embodiment approach 3

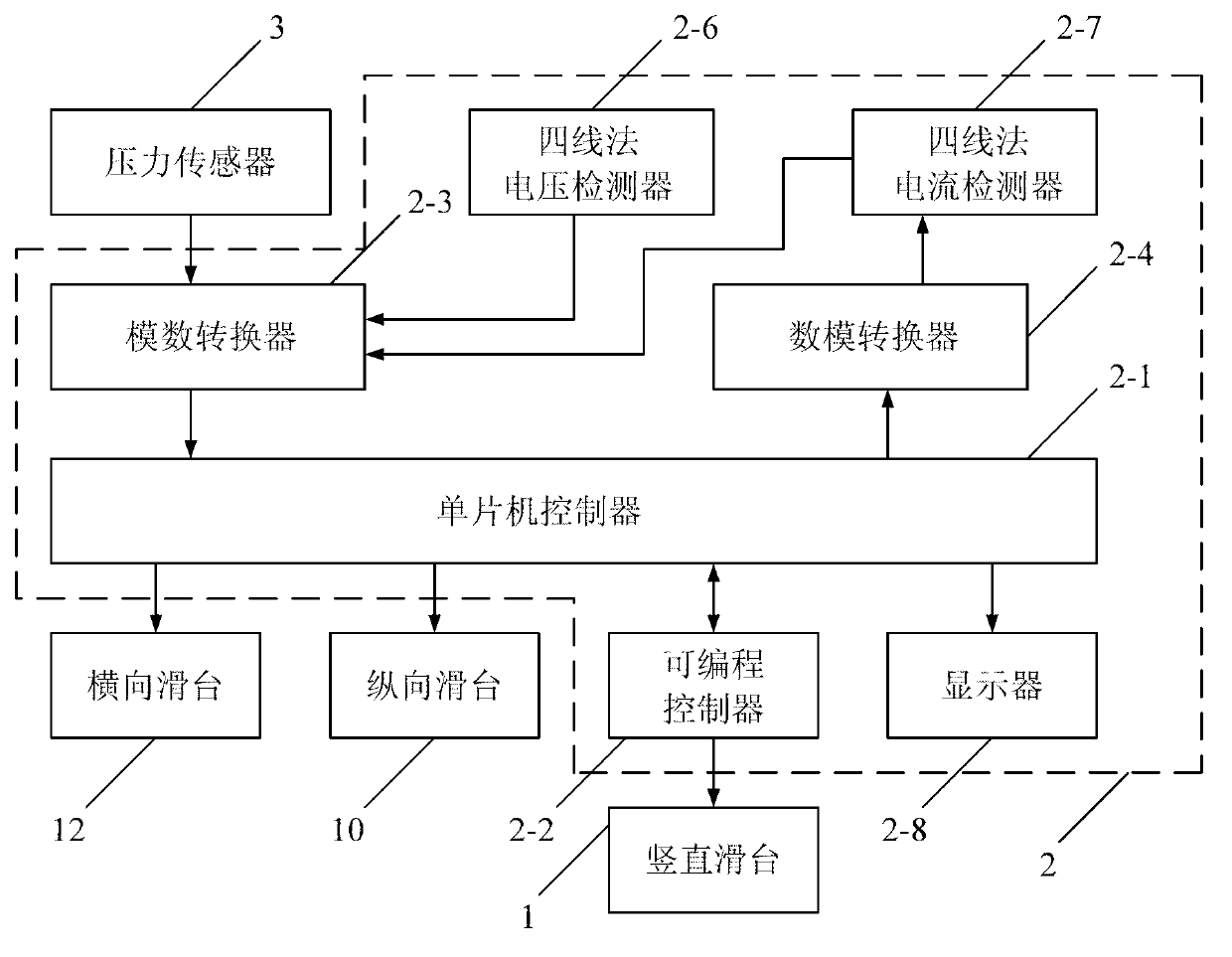

[0011] Specific implementation mode three: combination image 3 Describe this embodiment, the difference between this embodiment and the second embodiment is that the control assembly 2 also includes a display 2-7; the display data input end of the display 2-7 is connected with the display data output end of the single-chip controller 2-1 . Other compositions and connection methods are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com