A light guide plate with a hole and a method of making the same

A technology with a light guide plate and a hole is applied in the field of light guide plate, which can solve the problems of inability to change the light distribution curve, monotonous and unchanged light guide point, etc., and achieve the effect of vivid and beautiful appearance, improved practicability and artistry, and reduced cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

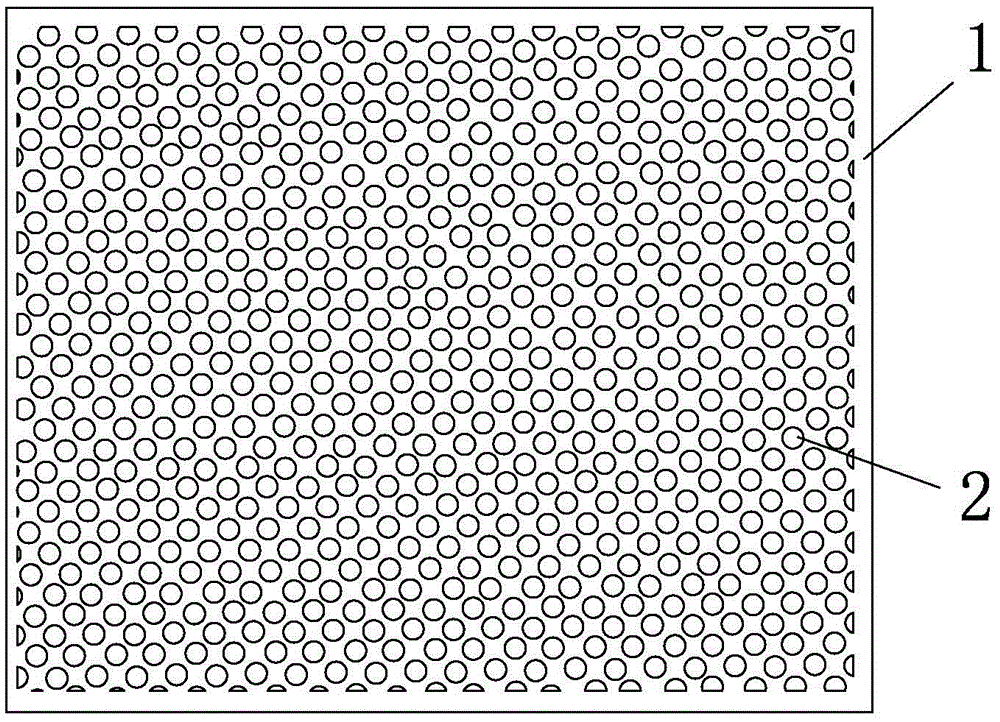

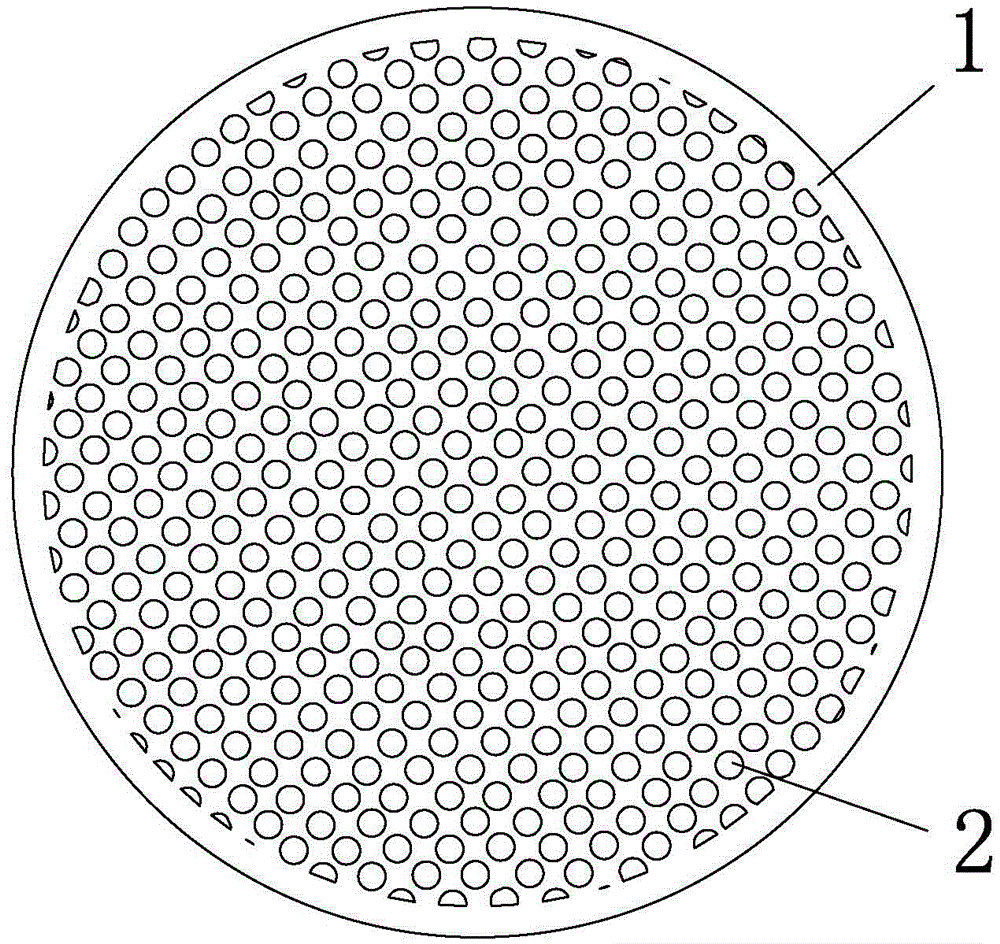

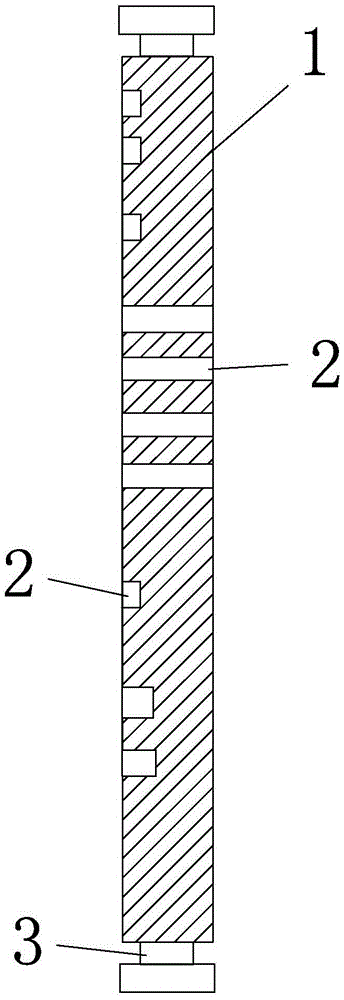

[0034] Such as Figure 1 to Figure 10 As shown, the light guide plate with holes proposed by the present invention includes a plate body 1 and a light source 3 disposed on the side of the plate body, and at least one side of the plate body is provided with a light guide hole 2 .

[0035] see image 3 , Figure 4 , the light guide holes 2 of the present invention can be blind holes (different depths) arranged on one or both sides of the light guide plate 1, or a mixture of blind holes and through holes, or all through holes. see Figure 5 ~ Figure 7 , said blind hole or through hole 2 can be a vertical hole or an inclined hole, or a mixed arrangement of vertical holes (90 degrees) and inclined holes (such as 45 degrees, 35 degrees, etc.). The shape of the light guide hole 2 can be a kind of circular hole, elliptical hole or polygonal hole, and can also be any mixed arrangement of vertical hole, oblique hole or polygonal hole. The aperture sizes of the light guide holes 2 ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com