Device and method for sterilization of the internal walls of containers with a reflector device for e-beam

A reflector, equipment technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

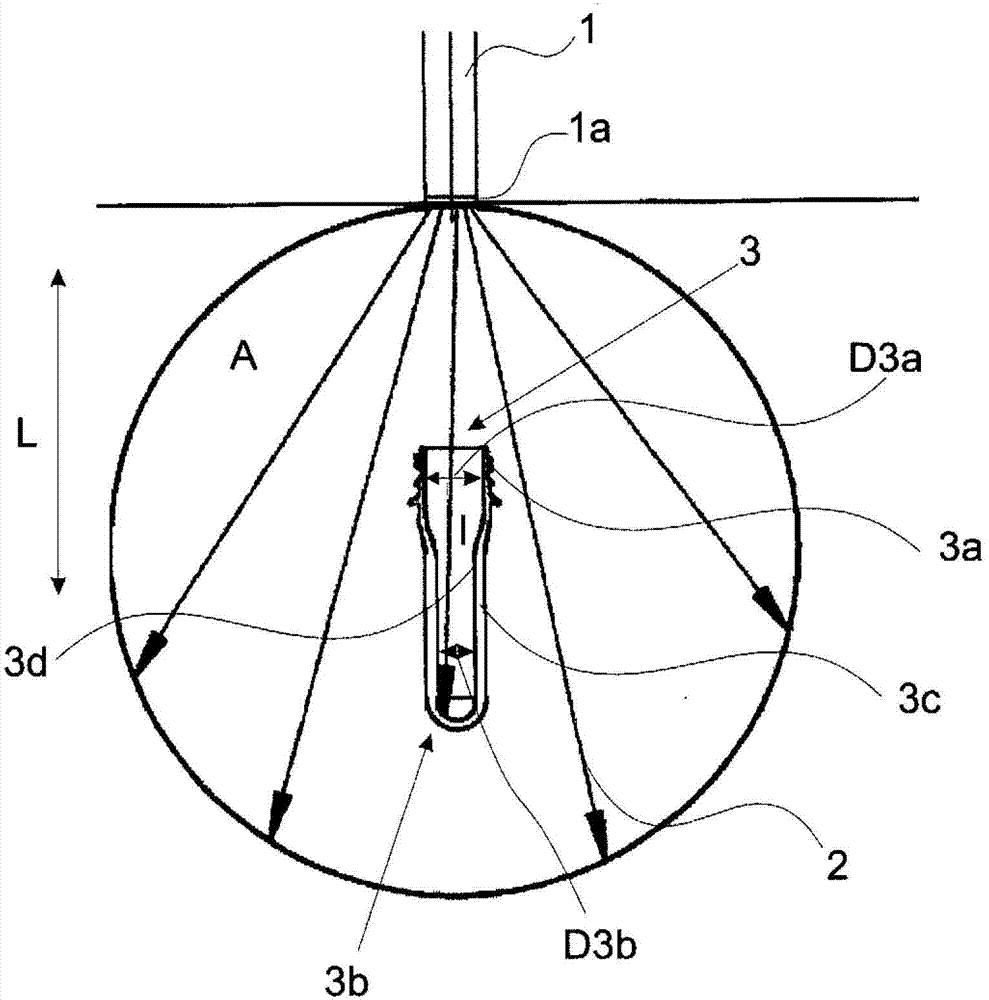

[0056] figure 1 is a sterilization device 1 or electron beam emitter 1 known in the prior art for sterilizing containers with an electron beam 2 , as well as an embodiment of a preform 3 and a basic design of the electron beam 2 impinging on this preform 3 .

[0057] The illustrated embodiment of the preform 3 has a diameter D3a or inner diameter D3a correspondingly in the aperture area 3a which is larger than the corresponding diameter D3b or inner diameter of the lower area 3b D3b, so that, as already explained above, a complete sterilization of at least the lower extent 3b of the preform 3 will take place using the radiation fingers known from the known prior art.

[0058] Without suitable equipment, such as reflector equipment, the electron beam 2 emitted by the electron beam emitter 1 can only emerge from the exit window 1 a in a non-directional manner and finally reach the inner region of the preform 3 partially I or the inner space I, or not at all into the inner regio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com