Printing apparatus and printing method

一种印刷装置、检测装置的技术,应用在印刷、印刷机、印刷工艺等方向,能够解决焊料量不稳定等问题,达到焊料量稳定的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach )

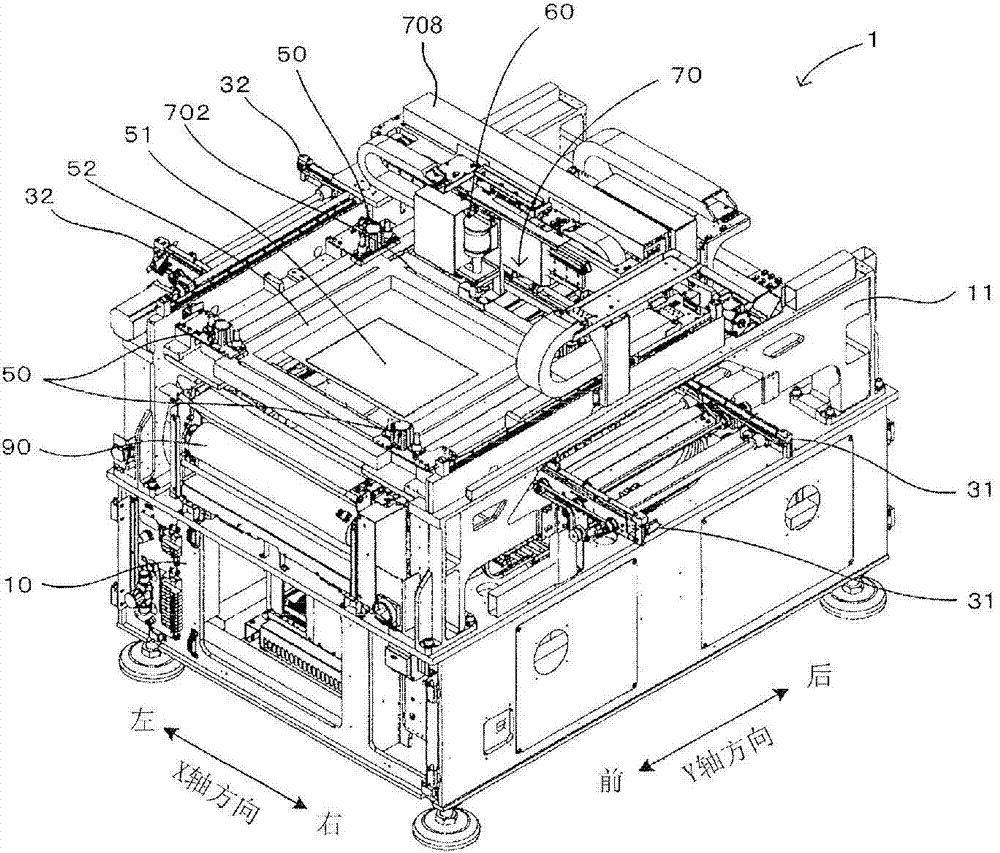

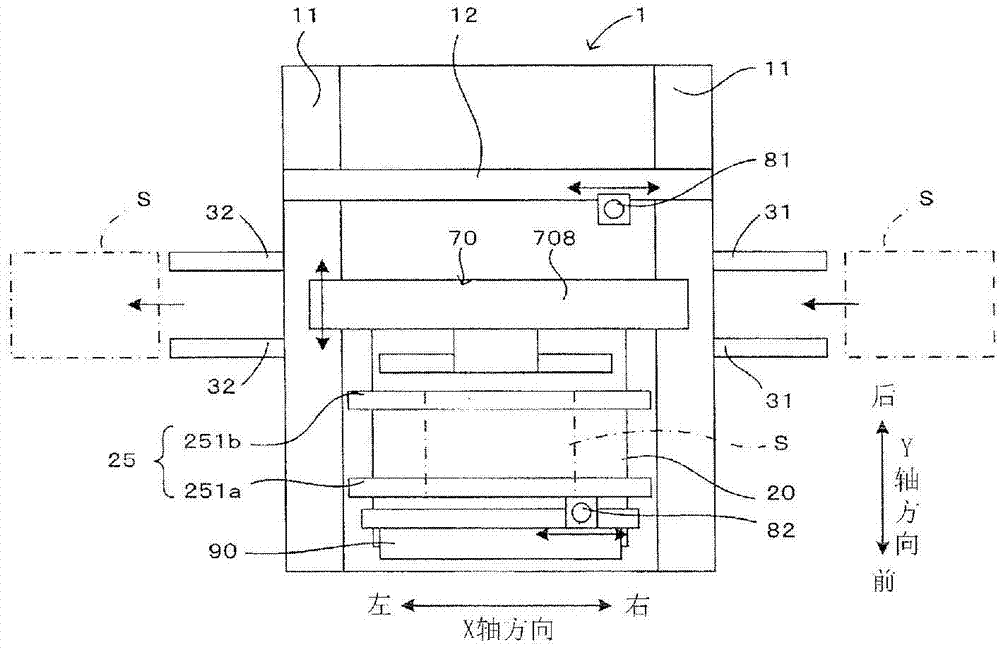

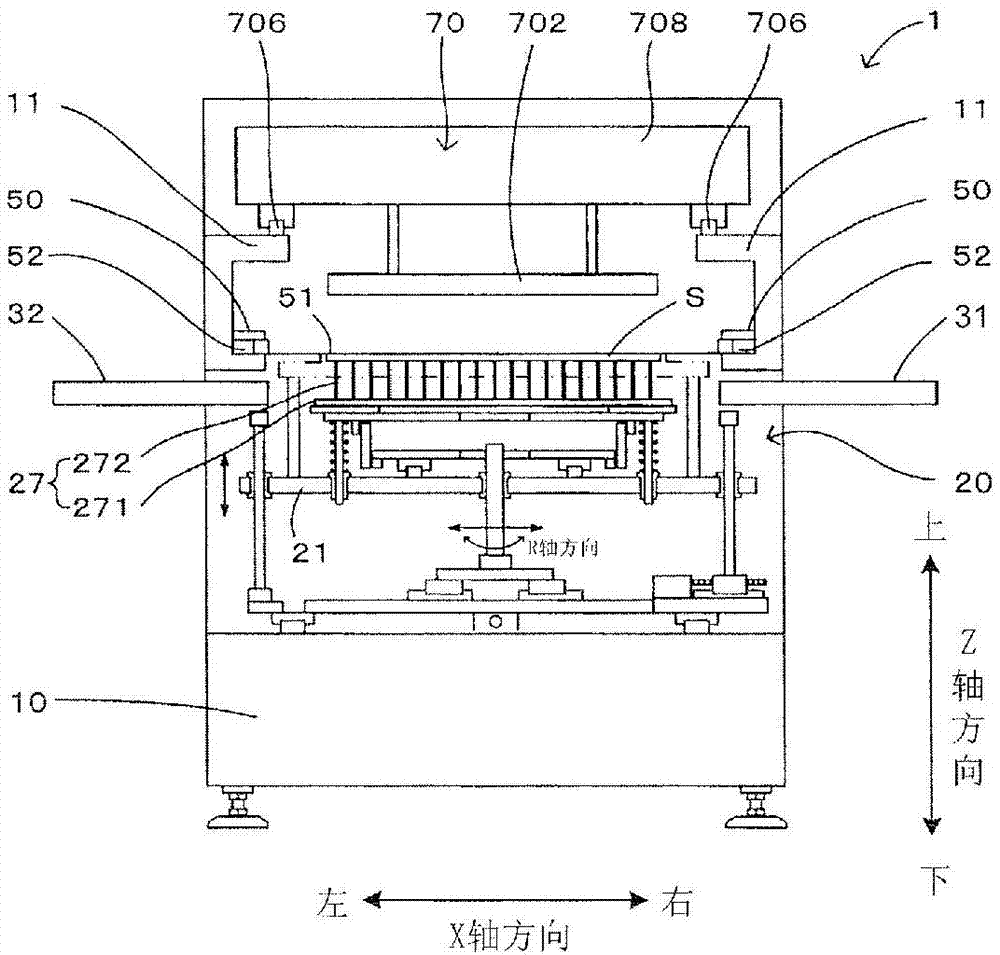

[0023] figure 1 It is a perspective view showing an example of a printing apparatus to which the present invention can be applied. In this figure, in order to clearly show the internal structure of the device, the state with the main body cover removed is shown in the figure. figure 2 is the state where no mask is set figure 1 The top view of the schematic structure of the printing device, image 3 is the state in which the mask is set figure 1 A side view of the schematic structure of the printing device. Figure 4 It is a block diagram showing the main electrical configuration of the printing device.

[0024] This printing apparatus 1 performs a predetermined printing process on the substrate S carried in from the right side, and then carries it out to the left side. This printing apparatus 1 is provided with a board|substrate conveyance mechanism 20 movable in the front-back direction (Y-axis direction) of an apparatus on the base 10. As shown in FIG. This printing a...

no. 2 approach )

[0061]In the above-described embodiment, the printing pressure of the squeegee 702 is adjusted based on the detection value of the width W of the solder pool SP. On the other hand, in the second embodiment described below, based on the detection value of the width W of the solder pool SP, the distance between the squeegee 702 (working surface 702 a ) contacting the surface of the mask 51 and the surface of the mask 51 is adjusted. The angle of attack α (in other words, the angle at which the squeegee 702 abuts against the surface of the mask 51 ). Specifically, in the second embodiment, the angle of attack α is adjusted instead of Figure 7 Step 106 of printing pressure adjustment. In addition, since the second embodiment is the same as the above-mentioned embodiment in other points, in the following description, corresponding symbols are assigned to the same parts, and explanations are appropriately omitted. In addition, needless to say, in the second embodiment, the same e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com