Split type elevator traction machine base

An elevator traction machine and split-type technology, which is applied to elevators, lifts, transportation and packaging in buildings, etc., can solve the problems of large level error of the traction machine base, inconvenient installation, unfavorable installation and adjustment, etc. The effect of saving the height of the top layer, easy installation and adjustment, and improving installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

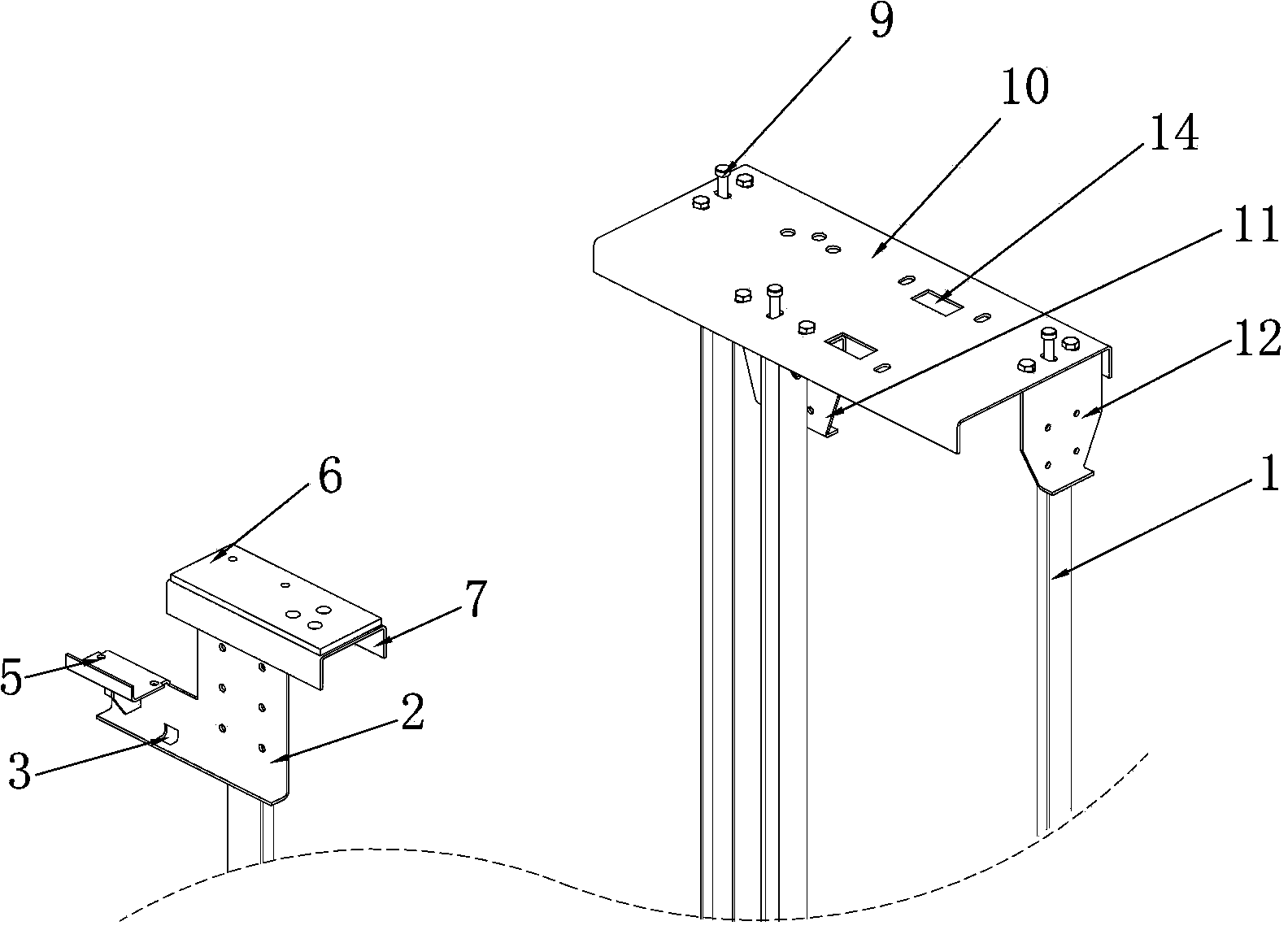

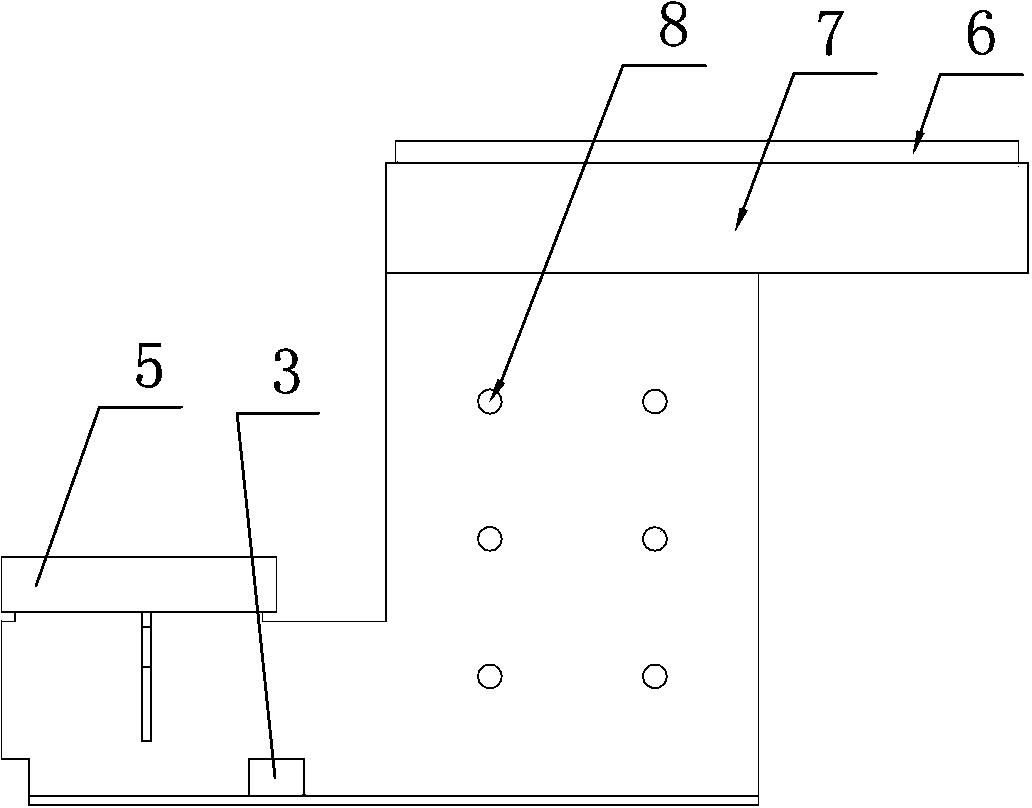

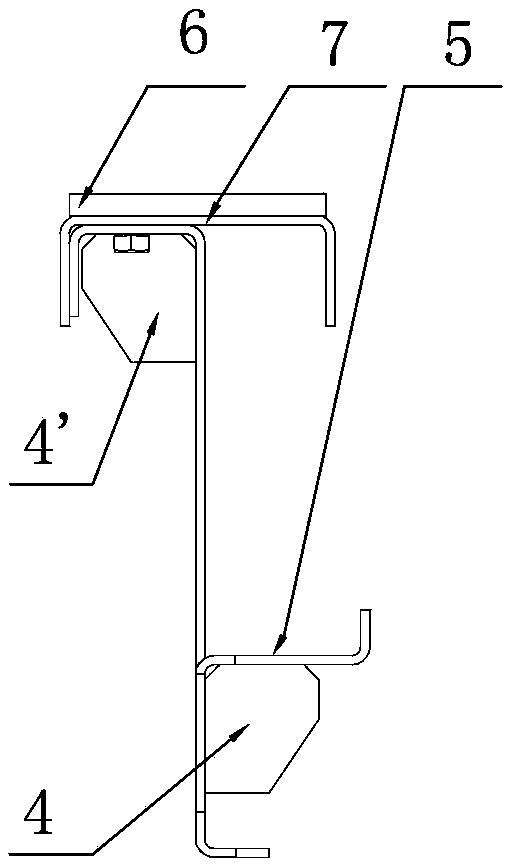

[0027] Example: such as figure 1 As shown, the present invention includes the speed governor base 2 installed on one side guide rail 1, the rope head plate 7 and the first, second and third hanging plates 11, 12, 13, traction machine on the other side guide rail Mounting plate 10, described rope end plate 7 is welded on speed governor base 2 tops, is also provided with a plurality of guide rail pressing plates of guide rail 1 on speed governor base 2; 12 and 13 are respectively installed on different guide rails 1, on which there are multiple guide rail pressure plates for installing the guide rail 1, and traction machine installation plates 10 are installed on the tops of the first, second and third hanging plates 11, 12 and 13 , there is a guide rail adjustment device installed on it relative to the first, second and third hanging boards 11, 12 and 13.

[0028] like figure 1 As shown, the guide rail adjusting device described in this example is the adjusting bolt 9 . Two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com