Production method for blueberry brandy

A production method, brandy technology, applied in the field of beverages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

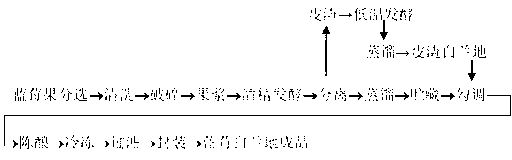

Image

Examples

Embodiment

[0040] The blueberry planted on a large scale in Xiasi Town, Majiang County, Guizhou Province, which has the largest blueberry planting area in China, is used as raw material. The anthocyanin content in 100g of fresh fruit is as high as 250mg, which has a comparative advantage in raw materials.

[0041] The blueberries are picked when the ripeness reaches the requirement, and the green and moldy fruits are manually screened, washed, crushed and beaten, and fermented within 4 hours to ensure the freshness and purity of the raw materials;

[0042] Then carry out raw material adjustment: the raw material wine of brandy is counted as 9%, and the sugar content of raw material is 19 ° Bx, and sugar content adjustment uses partly dehydrated fruit or concentrated juice; pH value is adjusted at 3.3;

[0043] Put the blueberry pulp into the fermentation tank, add 0.25g / kg active dry yeast, and control the temperature at 23°C~26°C for continuous fermentation for more than 10 days, with ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com