Lower floor board of system without screws

A screw-free and floor-less technology, applied in floors, buildings, building structures, etc., can solve the problems of unsightly appearance, complicated installation methods, low work efficiency, etc., and achieve the effect of uniform expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

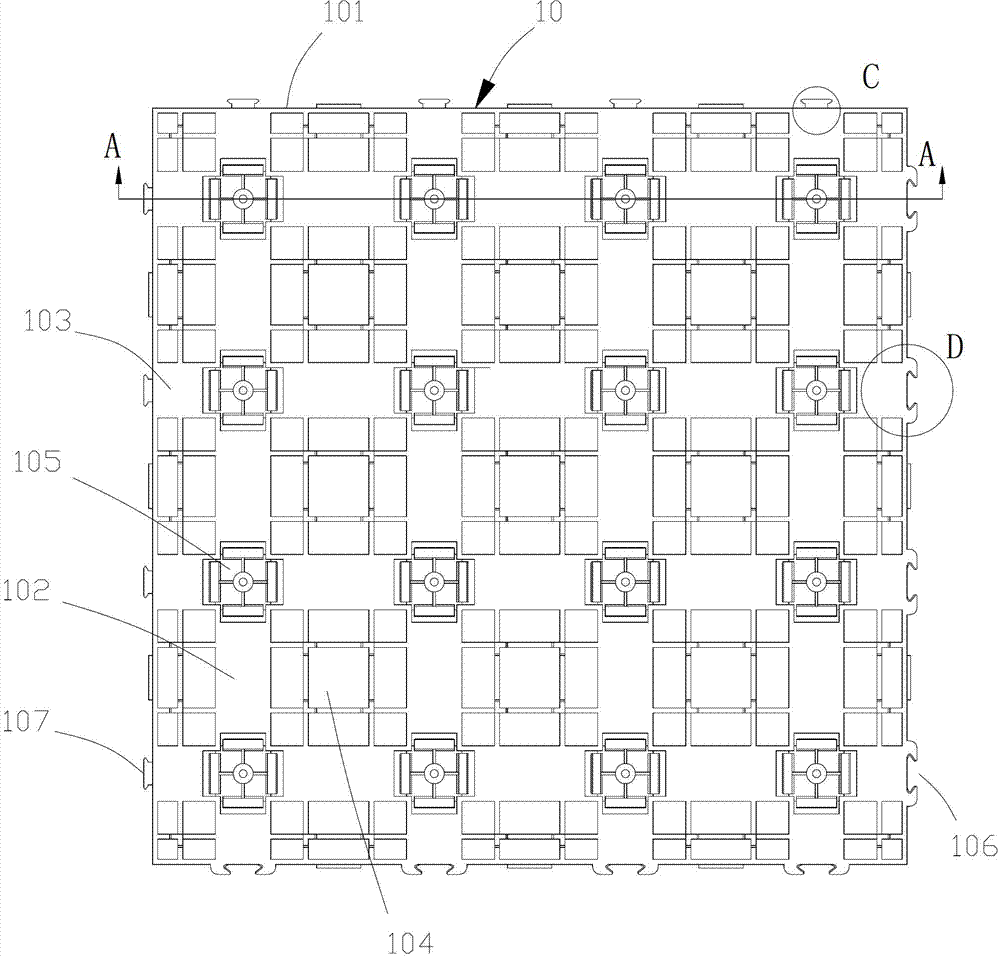

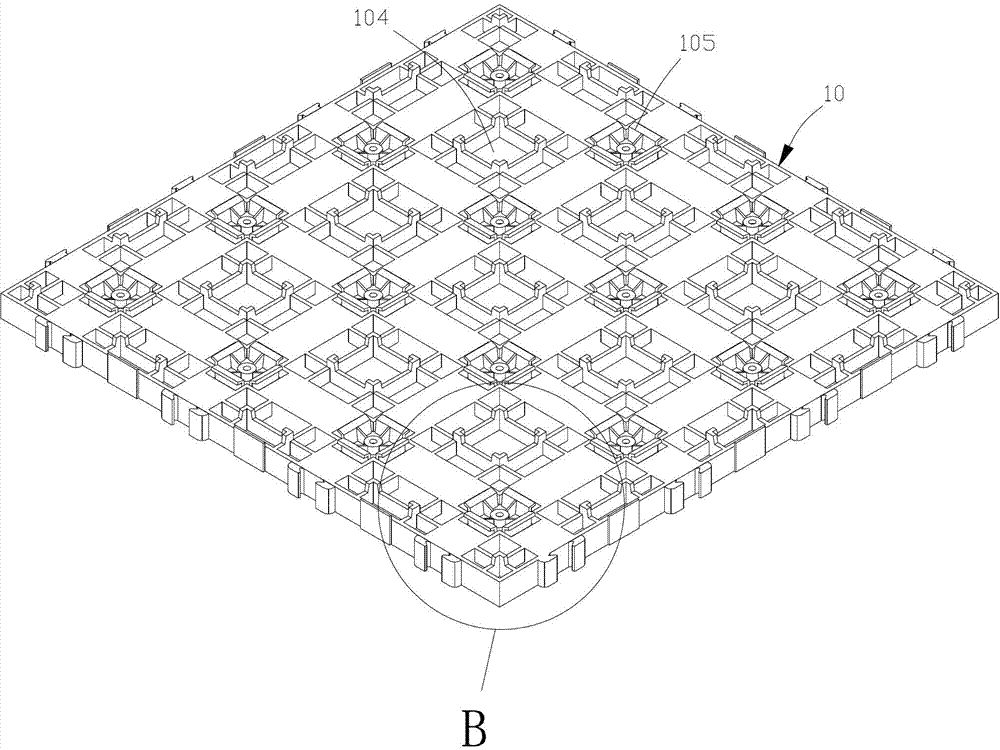

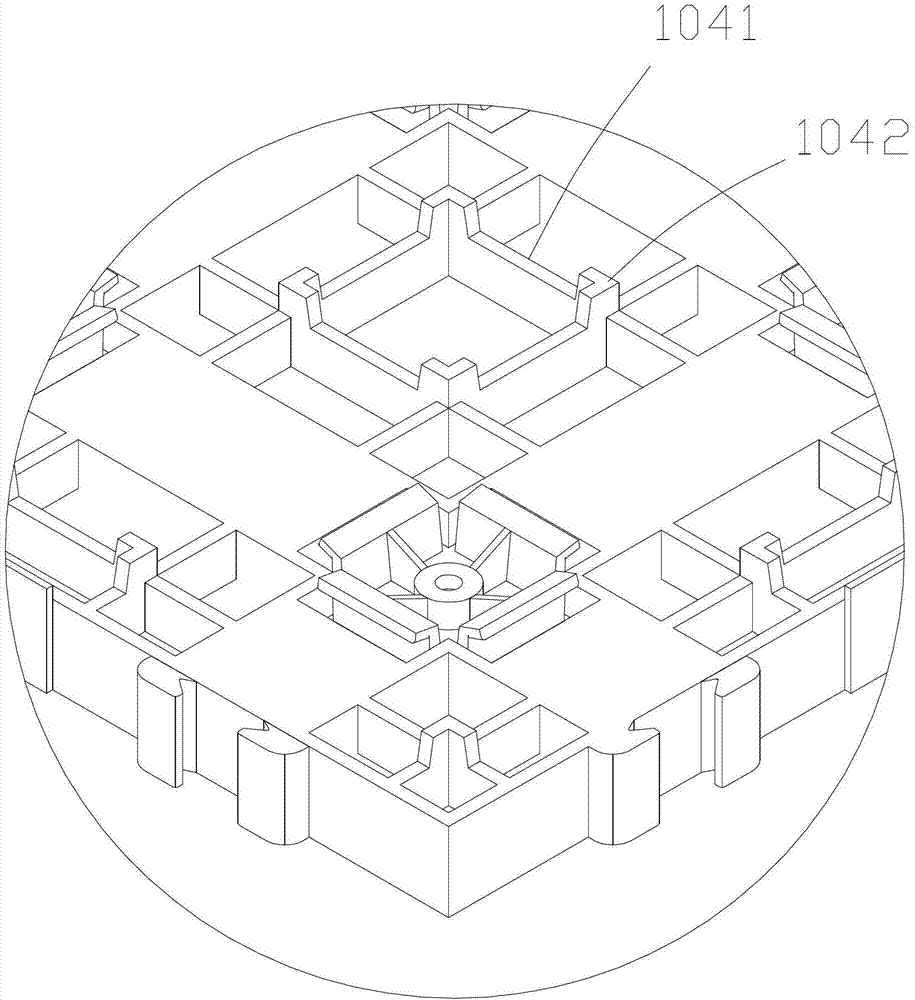

[0031] Such as figure 1 , figure 2 As shown, a screwless system lower floor includes a net bottom 10 with a square structure as a whole for supporting the floor. A number of longitudinal connecting bones 102 and transverse connecting bones 103 are integrally arranged longitudinally and horizontally between the slats 101. The longitudinal connecting bones 102 and the transverse connecting bones 103 connect the surrounding slats 101 together to form the net bottom 10. The longitudinal connecting bones 102 and the horizontal connecting bone 103 are integrated with the slat 101. The longitudinal connecting bone 102 and the horizontal connecting bone 103 intersect vertically, and a plurality of floor installation areas 104 with the same shape and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com