Simplex sleeve expansion joint

A technology of expansion joints and sleeves, applied in the field of expansion joints, can solve the problems of shortening the service life, reducing the performance, poor sealing, etc., and achieving the effect of prolonging the service life, improving the performance and improving the sealing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below in conjunction with the accompanying drawings.

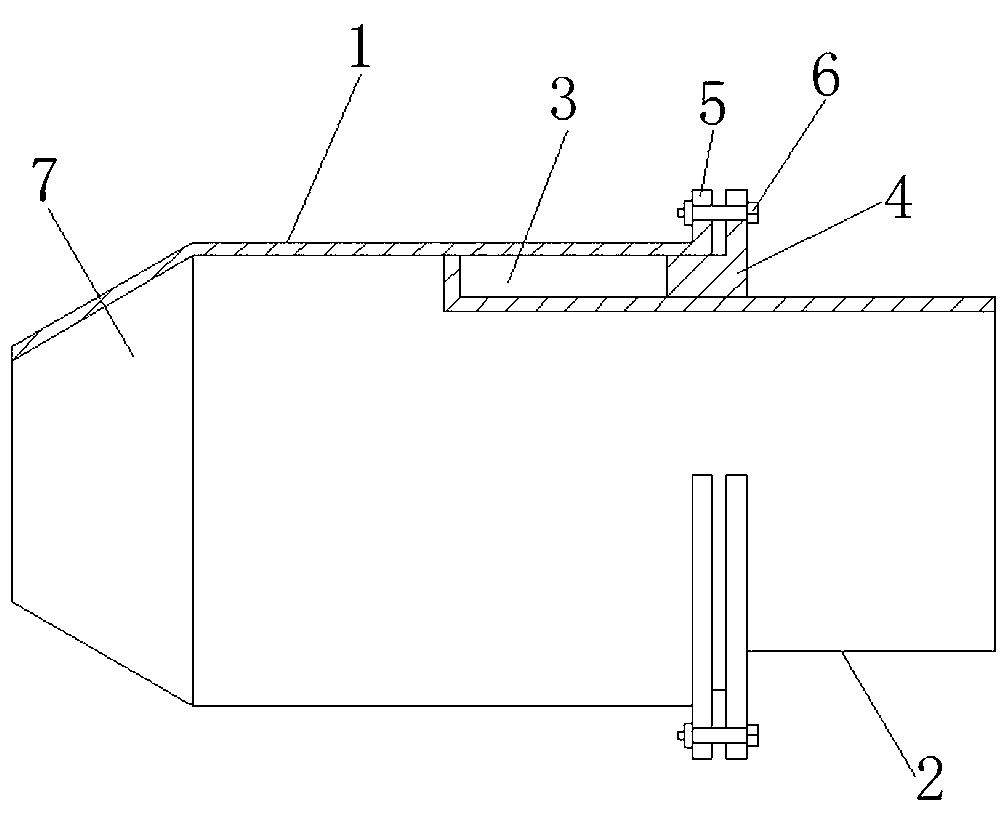

[0012] Such as figure 1 As shown, the single sleeve expansion joint includes an outer sleeve 1 and a moving tube 2, the outer layer of the moving tube 2 is sleeved with the outer sleeve 1, and the outer wall of the moving tube 2 and the inner wall of the outer sleeve 1 A sealing groove 3 is formed between them, and the sealing filler is filled in the sealing groove 3; in this embodiment, the sealing filler is filled in the sealing groove between the moving tube and the outer casing, so that when the moving tube moves freely in the outer casing, the expansion and contraction is also ensured. The sealing effect of the joint, thereby improving the performance of the expansion joint.

[0013] The sealing packing is graphite sealing packing, and the service life of the expansion joint can be prolonged because the graphite sealing packing has the characteristics o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com