Device for measuring coaxiality of oil injector installation hole and oil injector head installation hole of cylinder cover

A technology for installing holes and fuel injectors, which is applied in the direction of measuring devices, mechanical measuring devices, instruments, etc., can solve the problems of affecting the quality of parts, complicated measuring procedures, and high costs, and achieve the effects of cost saving, product quality assurance, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

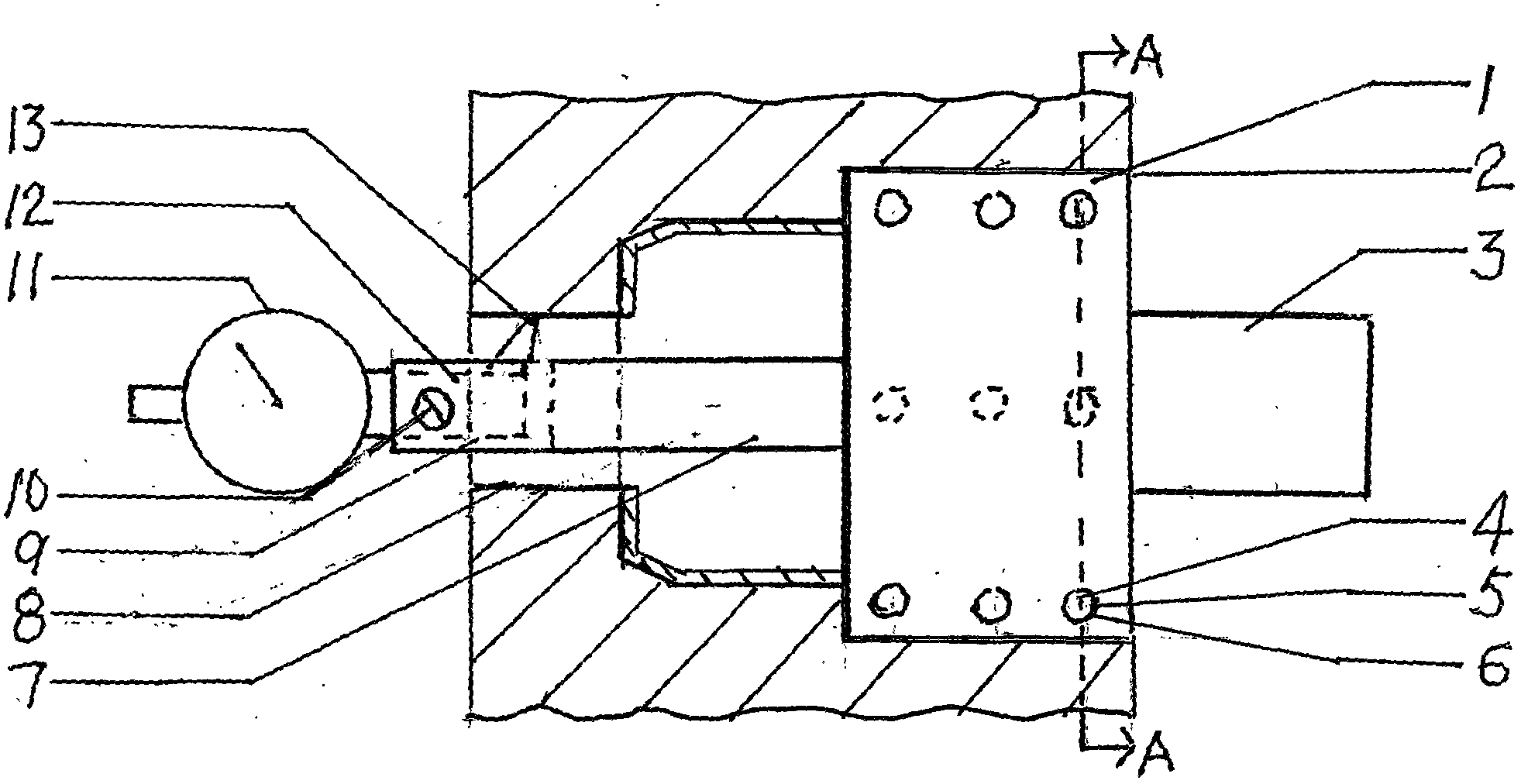

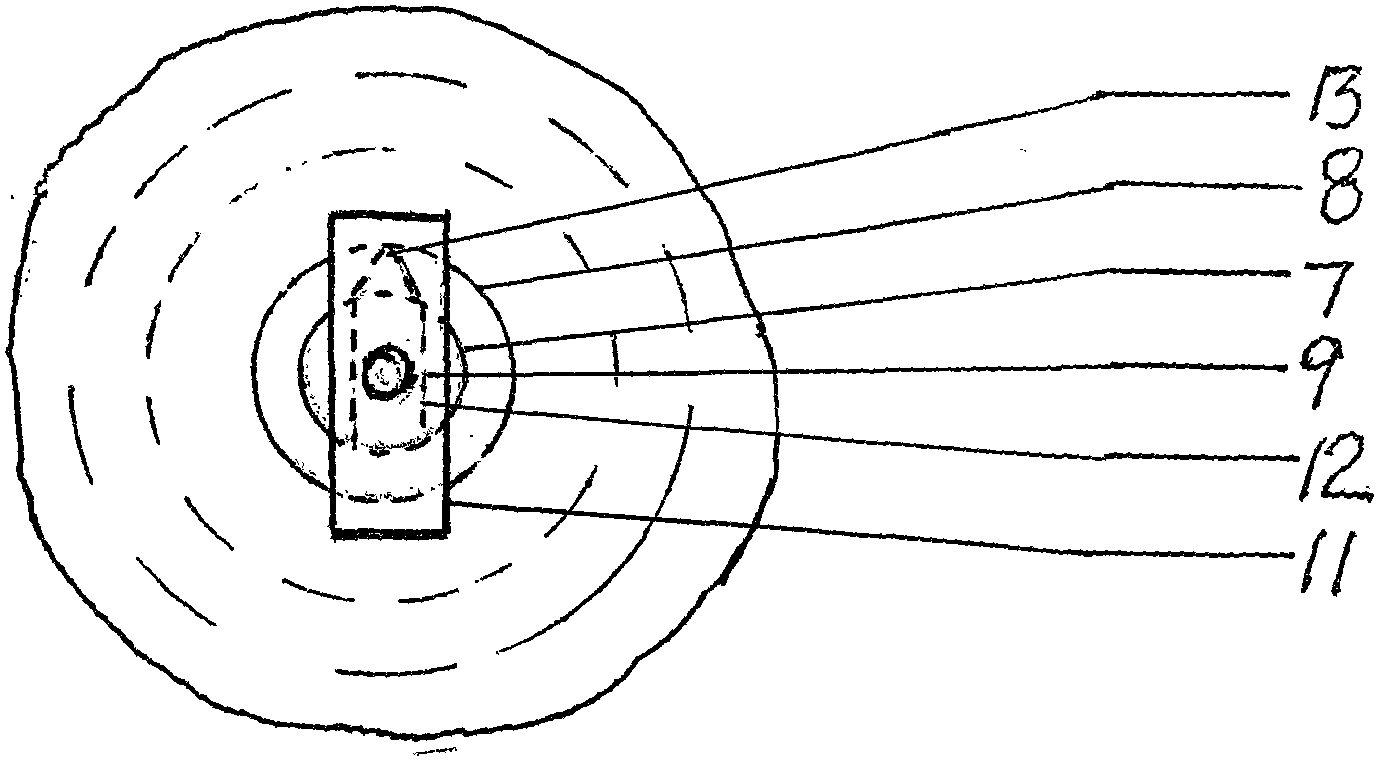

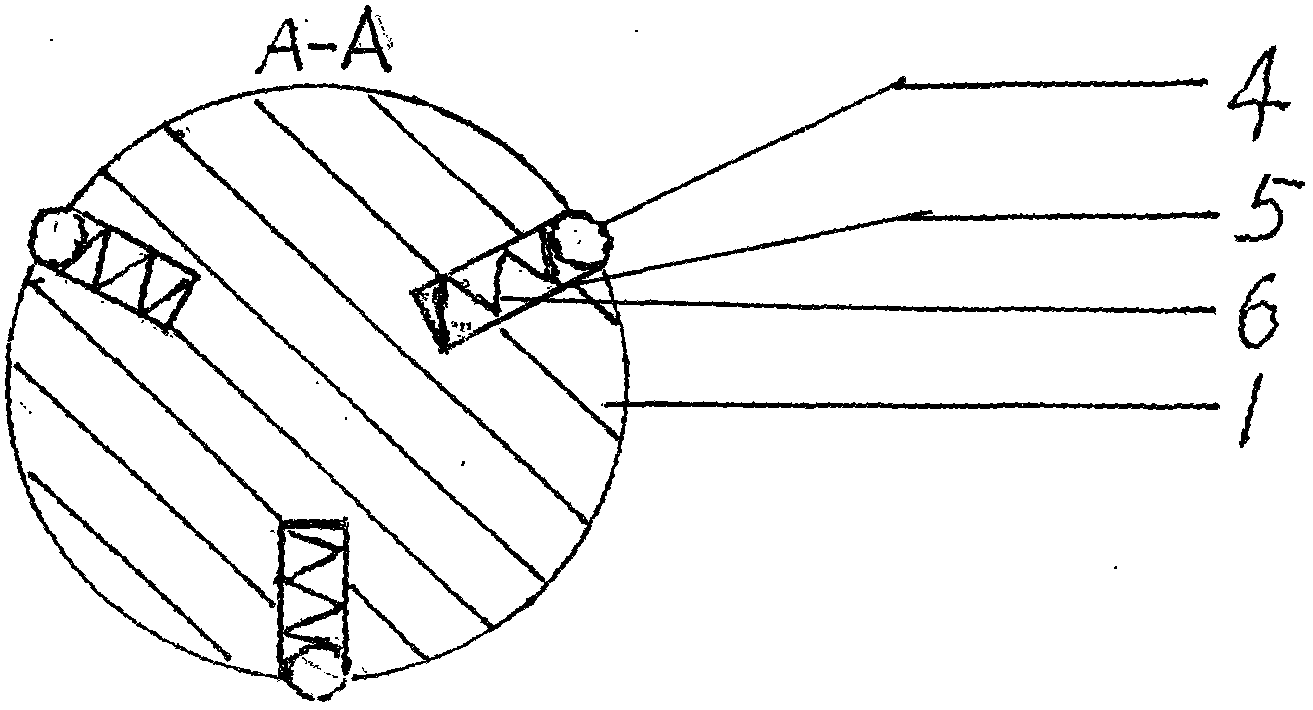

[0012] The attached drawing is a structural diagram of the measuring device for the coaxiality between the installation hole of the fuel injector of the 16V280 type cylinder head and the installation hole of the fuel injection head. in the attached figure 1 , 2 In 3, the expandable mandrel (1) with a diameter of Φ69.000 mm is horizontally distributed in an equilateral triangle, and three inner circles are Φ4.50 mm expansion bead installation holes (5), each expansion bead installation hole (5) Load a compression spring (6) with a diameter of φ4.00 mm and an expansion bead (4) with a diameter of Φ3.50 mm, press the expansion bead (4) into the expansion bead installation hole (5) with a shrinking tool The expandable mandrel (1) has three rows of expansion beads (4) evenly distributed in the longitudinal direction, and the height of each expansion bead (4) is the same as that of the outer circle of the expandable mandrel (1). The expansion force is 0.80 mm, and the expansion fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com