Ultra-precise 3D aiming and measuring sensor based on differential astigmatism and defocus detection

A technology for measuring sensors, astigmatism and defocusing, which is used in measurement devices, instruments, optical devices, etc., can solve the problems of conflict between the resolution and the lateral size of the sensor, and the common mode interference is difficult to eliminate, so as to improve the measurable aspect ratio. , low cost, the effect of increased stylus length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

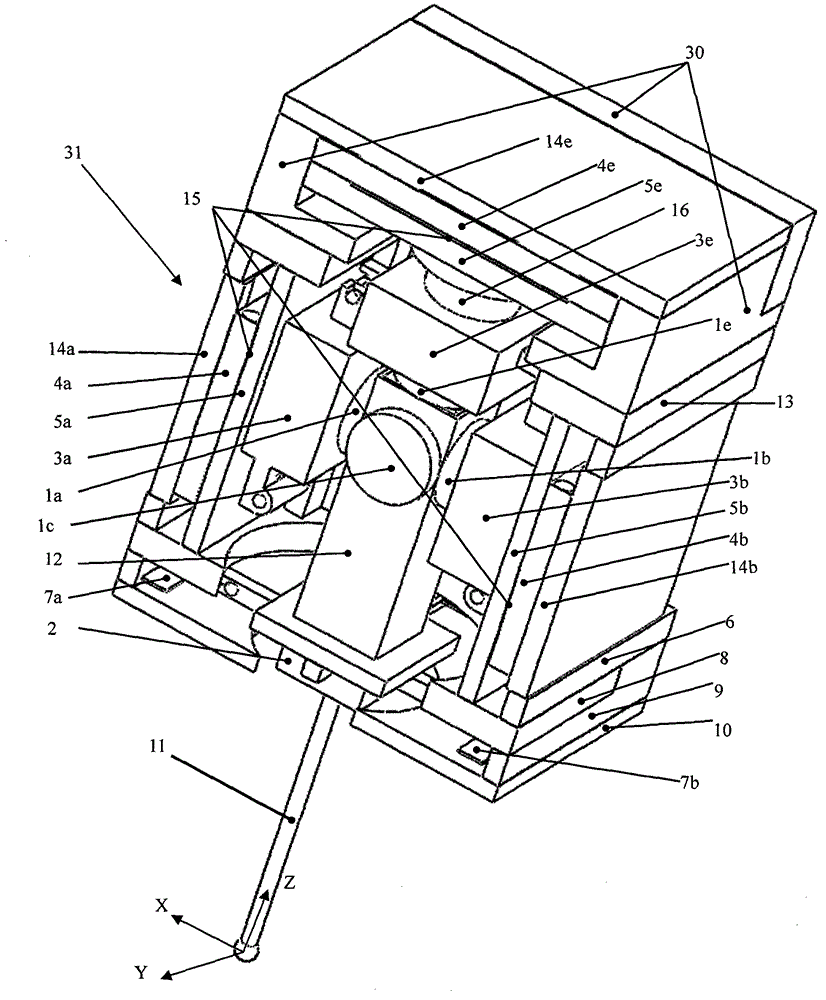

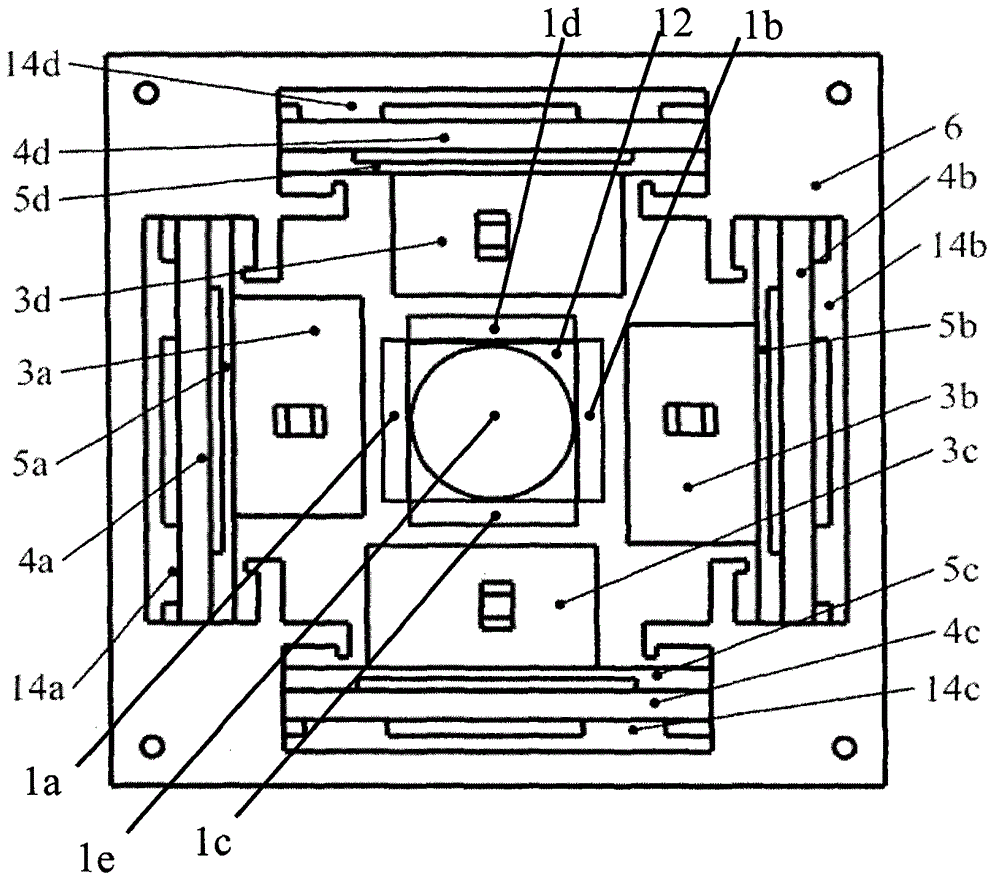

[0030] The specific implementation manner of the present invention will be described below with reference to the accompanying drawings, and examples will be given.

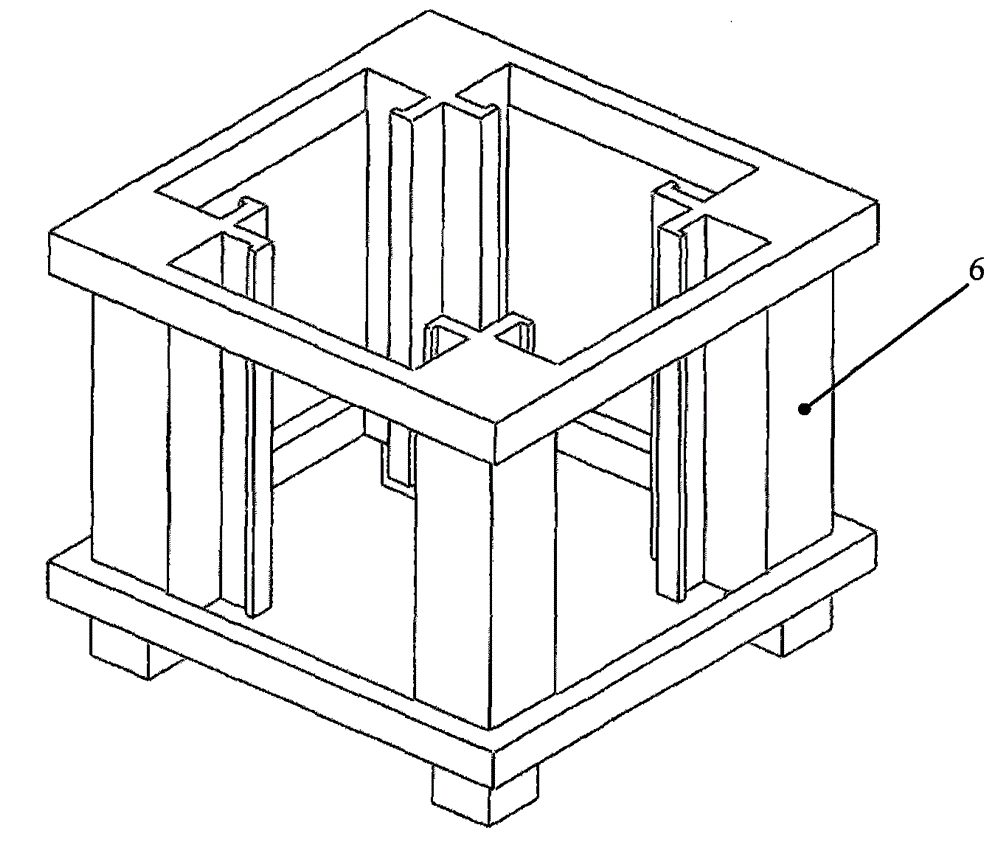

[0031] An ultra-precise three-dimensional aiming and measuring sensor based on differential astigmatism and defocus detection. It consists of an upper mounting side plate 30, a lateral micro-adjustment plate 13, a bracket 6, a lower baffle plate 8, a lower frame 9, a lower mounting plate 10, and a flexible suspension. Mechanism 29, sensing mechanism 31 is formed, and wherein on the upper end of support 6 successively fits horizontal micro-motion adjusting plate 13 and upper installation side plate 30, on the lower end of support 6 successively installs from top to bottom The lower baffle plate 8, the lower frame 9 and the lower mounting plate 10, the sensing mechanism 31 is assembled on the inside of the bracket 6, the flexible suspension mechanism 29 is installed on the lower end of the sensing mechanism 31, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com