A Plasma Immersion Implantation Electrode Structure

A technology of injecting electrodes and immersion injection, which is applied in the direction of circuits, discharge tubes, electrical components, etc., can solve problems such as injection pollution, achieve the effects of reducing edge effects, reducing sputtering pollution, and increasing injection uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

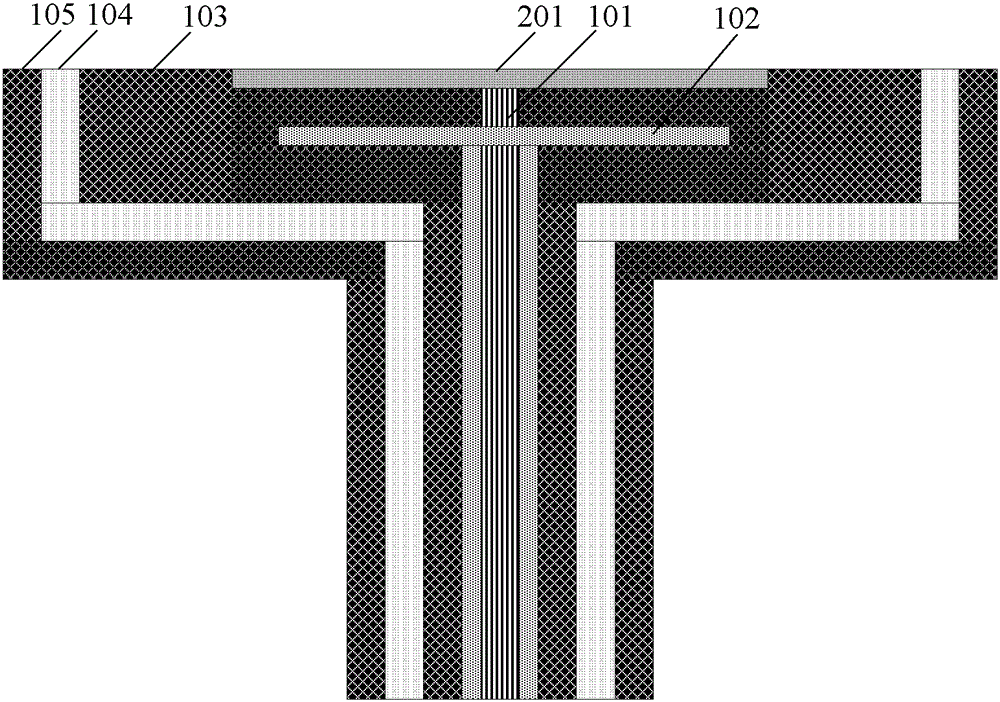

[0018] like figure 1 As shown, this embodiment provides a plasma-immersion injection electrode structure, which includes an injection electrode 103, an insulating layer 104, and a shielding layer 105 from the inside to the outside. The injection electrode 103 is connected to a bias power supply that provides a bias voltage, and the injection The electrode 103 is made of aluminum to reduce sputtering pollution during implantation. The insulating layer 104 is used for isolation and insulation of the injection electrode and the shielding layer. The shielding layer 105 is located at the outermost layer of the entire electrode structure and is made of aluminum. The shielding layer 105 is grounded and used for shielding the injection electrode 103 during injection to reduce sputtering pollution during injection.

[0019]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com