Rectification support frame and connecting body thereof

The technology of connecting body and rectifying hole is applied in the field of rectifying bracket and its connecting body, which can solve the problems of inconvenient cleaning, etc., and achieve the effects of convenient cleaning, reasonable split or conjoined structure, and rich functions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

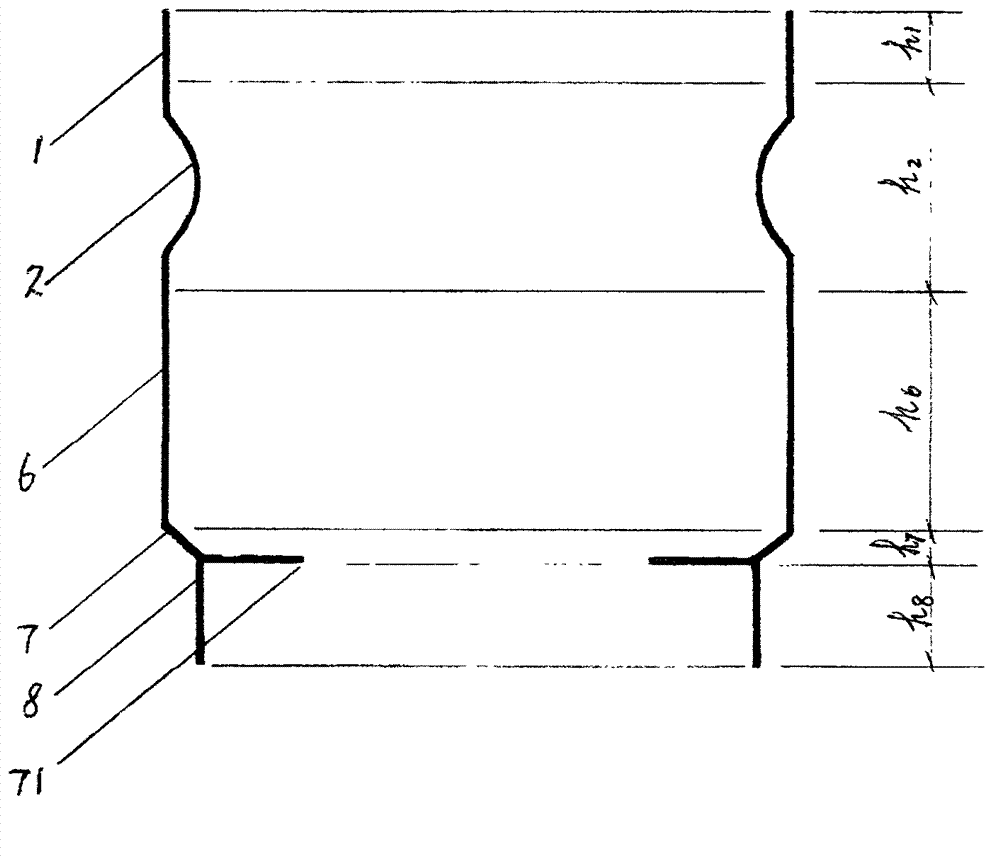

[0009] Embodiment 1: The rectification bracket and its connecting body, including the installation ring 1 of the h1 section, the connecting cylinder 2 of the h2 section, the fence body 6 of the h6 section, the lower rectification orifice plate 7 of the h7 section, and the rectification support feet 8 of the h8 section. The installation ring 1 consists of a The installation ring 1 has more than two mounting points. The upper opening of the installation ring 1 is horizontal and smooth. The connecting cylinder 2 is composed of a stainless steel cylinder with a diameter that gradually decreases in the middle. The fence body 6 is made of a stainless steel cylinder on the side. It is composed of penetrating holes around the fence, and the total area of the penetrating holes is 100 square millimeters to 5,000 square millimeters. The lower rectifying orifice plate 7 is a hole inlaid in the middle of the junction of the fence body 6 and the rectifying support feet 8. The stainless ste...

Embodiment 2

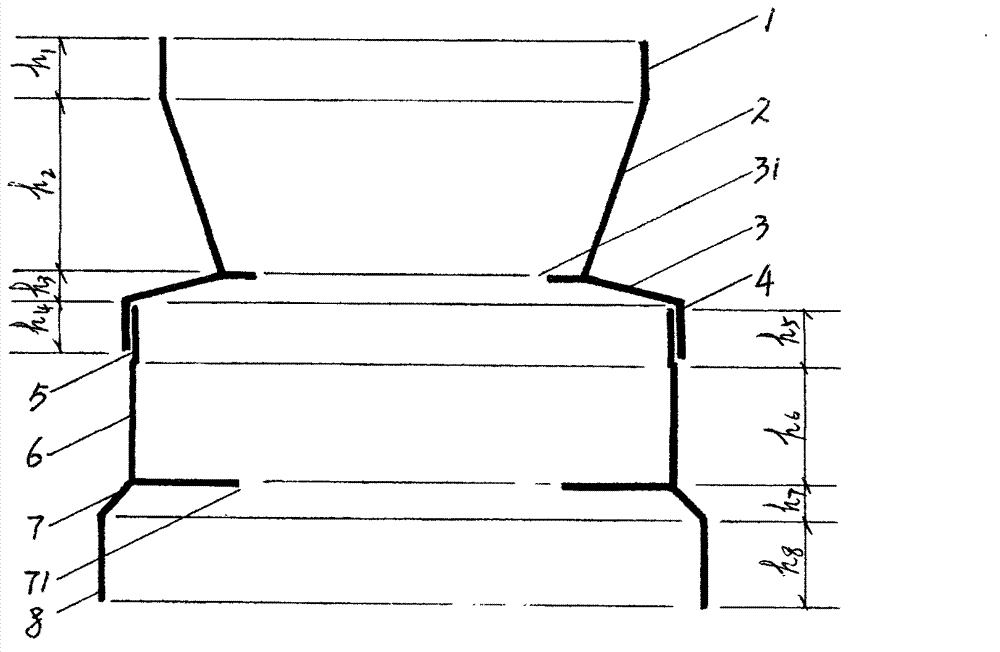

[0010] Embodiment 2: rectification bracket and its connecting body, including two parts of the connecting body and the rectifying bracket, that is, two split bodies, the connecting body includes the installation ring 1 of section h1, the connecting cylinder 2 of section h2, the upper rectification orifice plate 3 of section h3, The connection ring A4 of section h4, the installation ring 1 is composed of a stainless steel cylinder, the installation ring 1 has more than two installation points, the upper opening of the installation ring 1 is horizontal and smooth, the connection cylinder 2 is composed of a stainless steel cylinder, and the stainless steel cylinder is The side shape is rounded, and the upper rectifying orifice plate 3 is a stainless steel plate-shaped structure connected to the connecting cylinder 2 on the upper side and the upper and lower through-holes are opened in the middle of the connecting ring A4. The middle opening is the upper rectifying hole 31, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com