Glass tube sealing device

A sealing device and glass tube technology, applied in glass forming, glass reshaping, glass manufacturing equipment, etc., can solve the problems of high production cost, complex structure of solar heat collector tube sealing machine, etc., and achieve simple structure and high sealing processing efficiency Improves and evenly heats the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

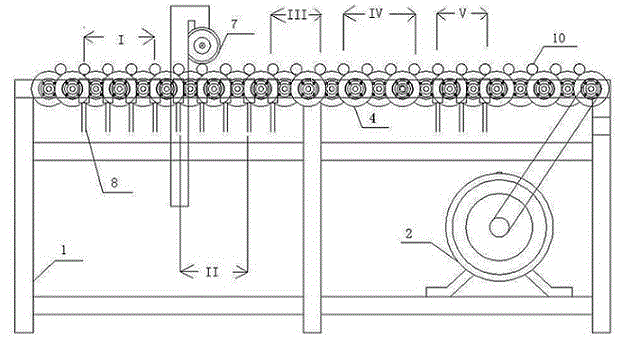

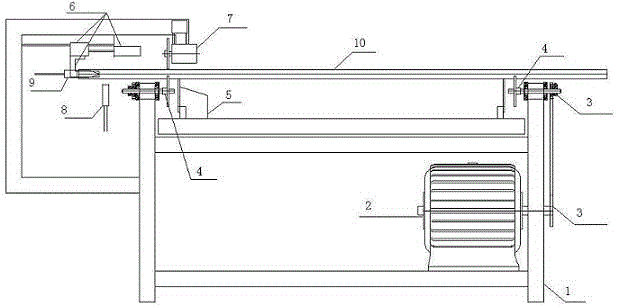

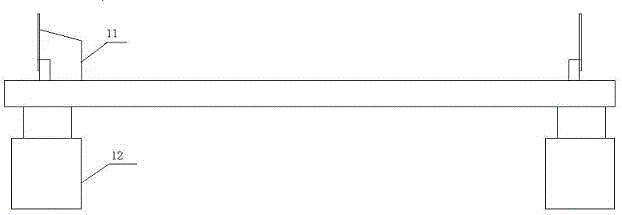

[0022] Such as figure 1 , 2 As shown, the present invention includes a frame 1, a transmission mechanism 3, and rollers 4, and adjacent rollers are arranged to overlap each other to form a conveying channel. The conveying channel includes preheating section I, sealing processing section II, cooling section III, perforating processing section IV (before piercing, the end surface of the glass tube must be solidified and slightly cooled before piercing), and heat preservation stage V five processing sections. At the outer end of the overlap of adjacent rollers, near the position of the glass tube 10 port, there are provided a sealing member 6 for sealing the glass tube and a preheating device 8 for melting the port of the glass tube 10, and the adjacent rollers A pressing device 7 for pressing the glass tube 10 and a perforating device 9 for punching the glass tube 10 are provided at the overlap. A displacement device 5 for displacing the glass tube 10 is also provided below th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com