Method for making core-shell polyhedral oligomeric silsesquioxane (POSS) coated multi-walled carbon nanotube (MWNT)

A technology of multi-walled carbon nanotubes and silsesquioxane, which is applied in the treatment of dyed organosilicon compounds, fibrous fillers, etc., can solve problems such as performance damage, difficulty in large-scale production, and structural breakage of carbon nanotubes. Achieve the effect of low cost and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

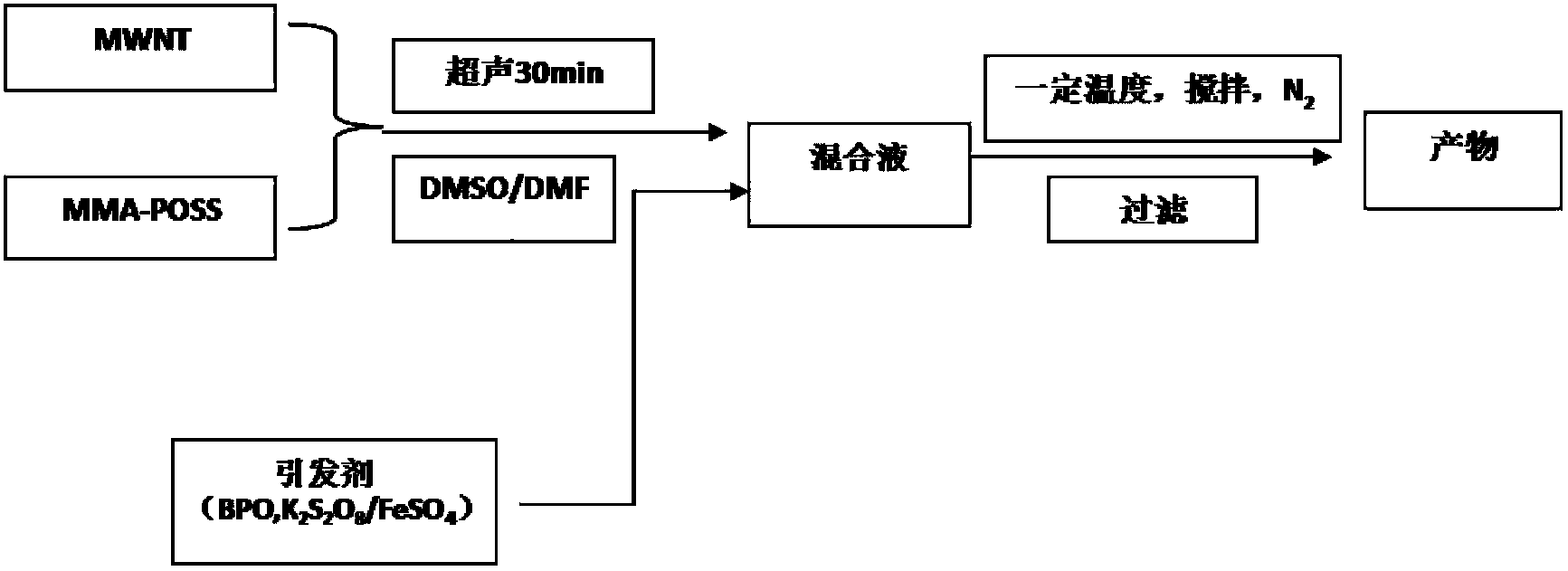

[0019] Weigh 50 mg of carbon nanotubes, place them in a three-necked flask, add 20 ml of DMF as a solvent, and ultrasonically disperse for 15 min. Weigh 250 mg of mma-POSS, add it into the above-mentioned three-necked flask, and sonicate for 15 min. Add 80ml of DMF solvent and sonicate for 15min. The three-necked flask was moved into an oil bath, under nitrogen protection, 12.5 mg of initiator benzoyl peroxide was added, and stirred at room temperature for 15 min. Raise the temperature to 80°C, react for 8 hours, and stop the reaction. The product was obtained by suction filtration, washed with N,N-dimethylformamide, dimethyl sulfoxide, deionized water, ethanol, and chloroform for 15 minutes, and finally the target product was obtained by suction filtration. figure 2 (a) is the core-shell composite powder of mma-POSS-coated carbon nanotubes prepared in this example (the specific flow chart is shown in Figure (1)). It can be seen from the figure that there is a thin layer o...

Embodiment 2

[0021] Weigh 50 mg of carbon nanotubes, place them in a three-necked flask, add 20 ml of DMF as a solvent, and ultrasonically disperse for 10 min. Weigh 500 mg of mma-POSS, add it into the above-mentioned three-neck flask, and sonicate for 15 min. Add 80ml of DMF solvent and sonicate for 15min. The three-necked flask was moved into an oil bath, under nitrogen protection, 12.5 mg of initiator benzoyl peroxide was added, and stirred at room temperature for 15 min. Raise the temperature to 80°C, react for 8 hours, and stop the reaction. The product was obtained by suction filtration, washed with N,N-dimethylformamide, dimethyl sulfoxide, deionized water, ethanol, and chloroform for 15 minutes, and finally the target product was obtained by suction filtration. figure 2 (b) is the core-shell composite powder of mma-POSS-coated carbon nanotubes prepared in this example. It can be clearly seen that there is a thick layer of coating material on the outer wall of the multi-walled c...

Embodiment 3

[0023] Weigh 50 mg of carbon nanotubes, place them in a three-necked flask, add 20 ml of DMSO as a solvent, and ultrasonically disperse for 10 min. Weigh 100 mg of mma-POSS, add it into the above-mentioned three-neck flask, and sonicate for 15 min. Add 80ml DMSO solvent and sonicate for 15min. Move the three-necked flask into an oil bath, and under the protection of nitrogen, add the initiator compounded by ferrous sulfate / potassium persulfate, including 13 mg of ferrous sulfate and 19.5 mg of potassium persulfate, and stir at room temperature for 15 min. Raise the temperature to 60°C, react for 8 hours, and stop the reaction. The product was obtained by suction filtration, washed with N,N-dimethylformamide, dimethyl sulfoxide, deionized water, ethanol, and chloroform for 15 minutes, and finally the target product was obtained by suction filtration. figure 2(c) is the core-shell composite powder of mma-POSS-coated carbon nanotubes prepared in this example. It can be clearl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com