fuel exhaust system valve

A technology of fuel system and exhaust valve, which is applied in the direction of charging system, liquid fuel feeder, and layout combined with internal combustion engine fuel supply, etc., can solve problems such as inability to handle liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

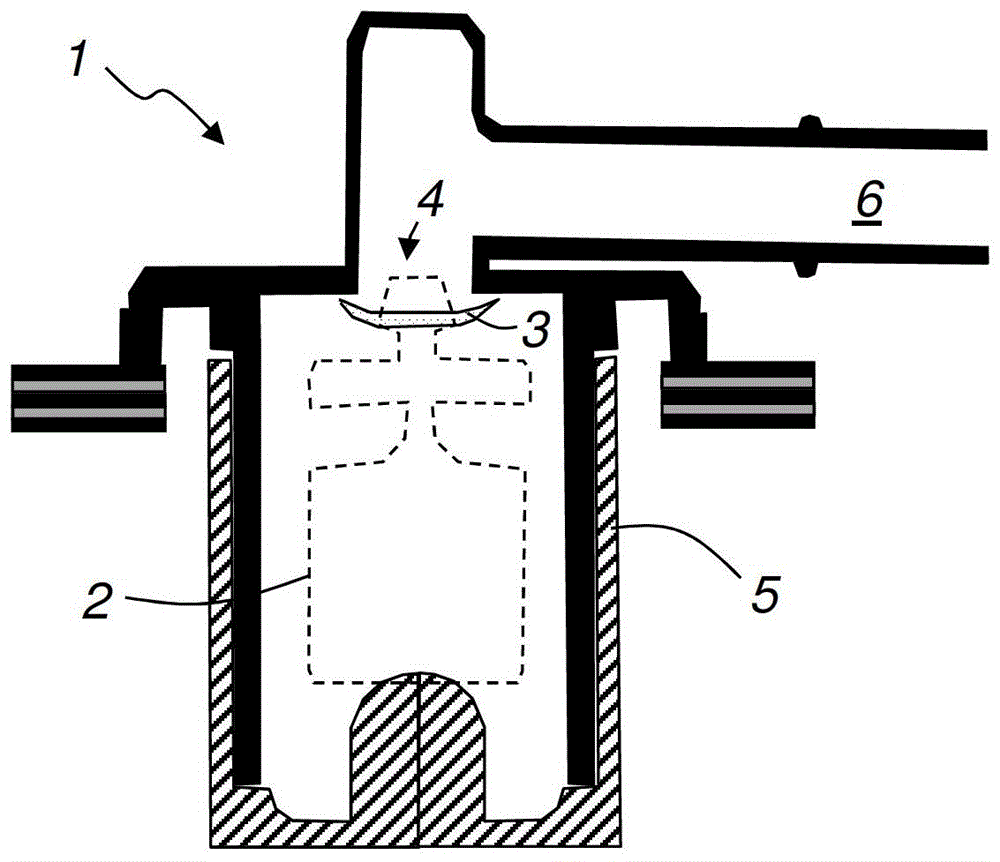

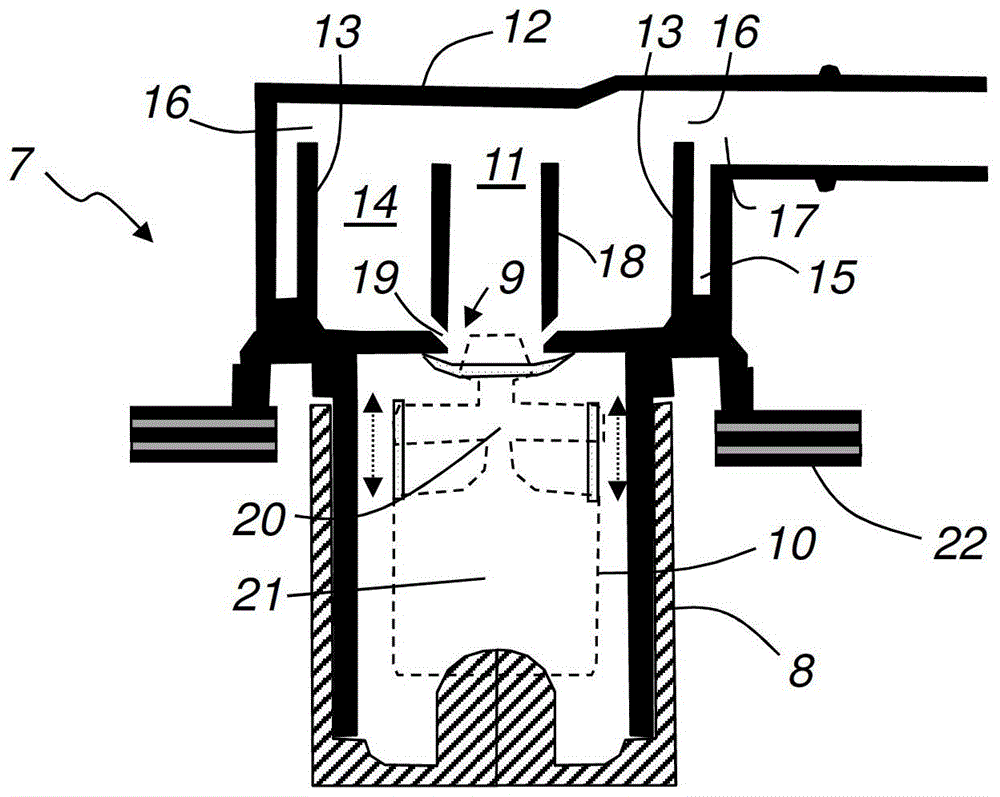

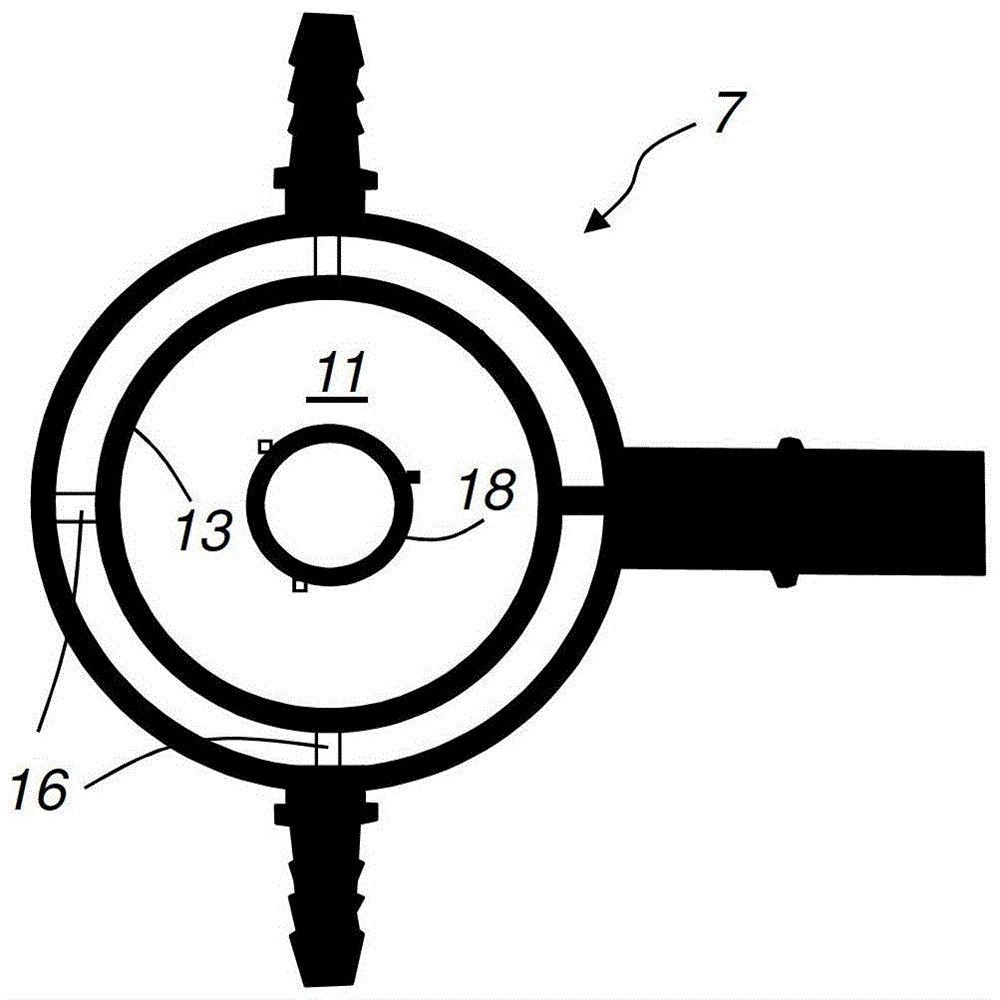

[0024] Such as figure 2 As can be seen in the figure, the fuel system exhaust valve 7 according to the present invention includes a housing 8 and a float 10 located in the housing 8 , and the housing 8 has a first opening 9 located in the upper part of the housing 8 . The float 10 is movable between a first position in which the valve 7 is open and a second position in which the float 10 covers the opening 9 so that the Said valve 7 is closed (as figure 2 shown). Said housing 8 also comprises several openings (not shown) at least on the sides of said housing 8 . Said valve 7 also comprises a liquid collector 11 arranged above said housing 8 so as to cover said first opening 9 . Said liquid collector 11 comprises its own housing 12 in which is arranged a peripheral wall 13 surrounding said first opening 9 . The peripheral wall 13 is arranged at a distance from the housing 12 of the liquid collector 11 so that a first volume space 14 inside the wall 13 and a second volume ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com