Level height difference correction system for four-wheel aligner lifting frame of standard-type automobile

A four-wheel aligner and leveling technology, which is applied in wheel testing and other directions, can solve the problems that the detection accuracy of the wheel aligner cannot be guaranteed, and the performance inspection of the wheel aligner cannot be performed, so as to achieve the effects of low production cost, weight reduction, and convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

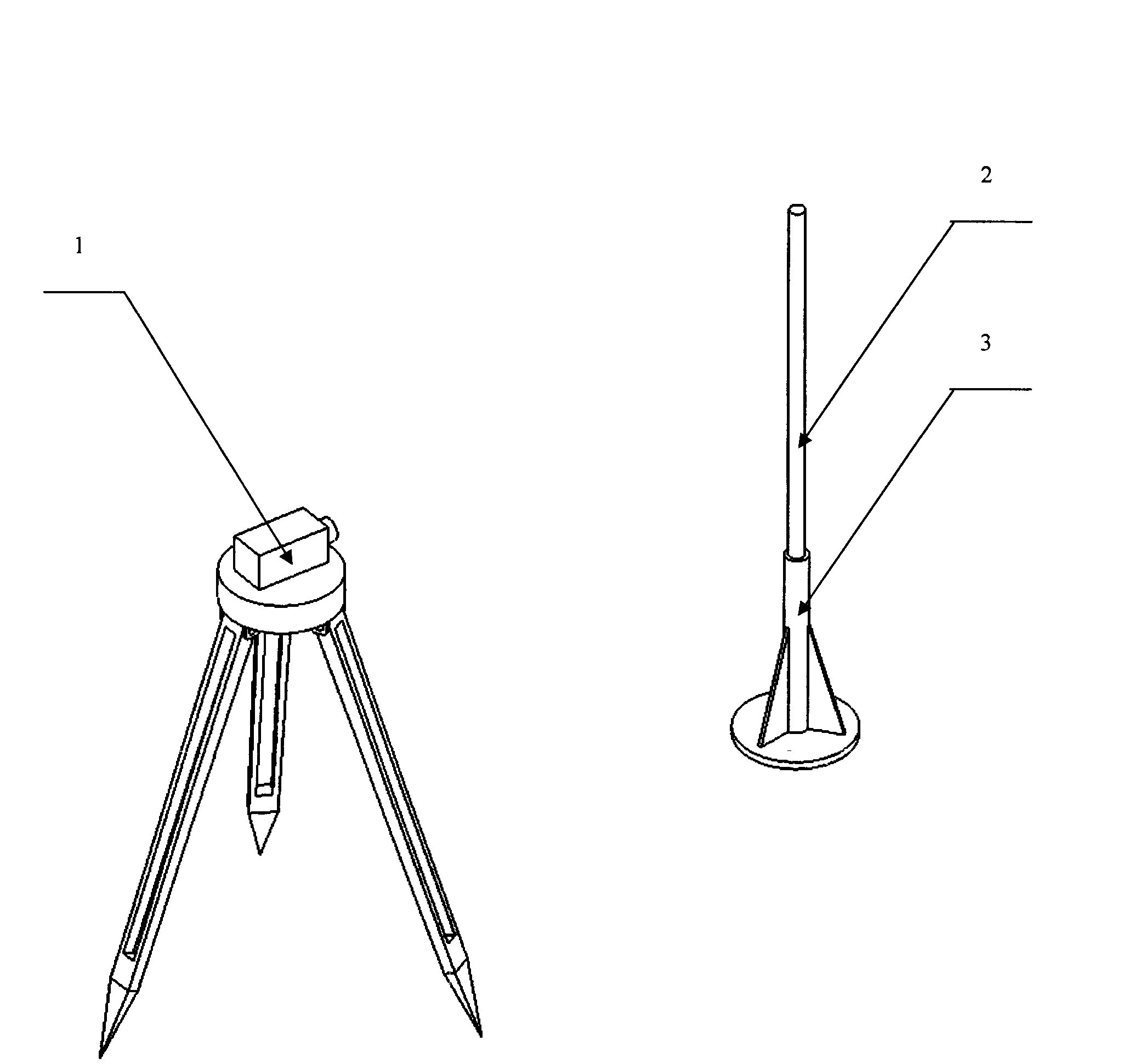

[0020] Below in conjunction with accompanying drawing, the present invention will be described in further detail:

[0021] The invention has the function of checking and correcting the level difference between the lifting frame of the automobile four-wheel aligner and the contact points of the automobile wheels, and can directly read the height of each point through the scale of the benchmark. The accuracy of the correction system is higher than that of the national standard for automobiles. The requirements of the height difference between the four-wheel aligner lifting frame and the contact points of the car wheels can meet the requirements of the national quality supervision department and manufacturers for on-site rapid inspection of the quality of the four-wheel aligner lifting frame.

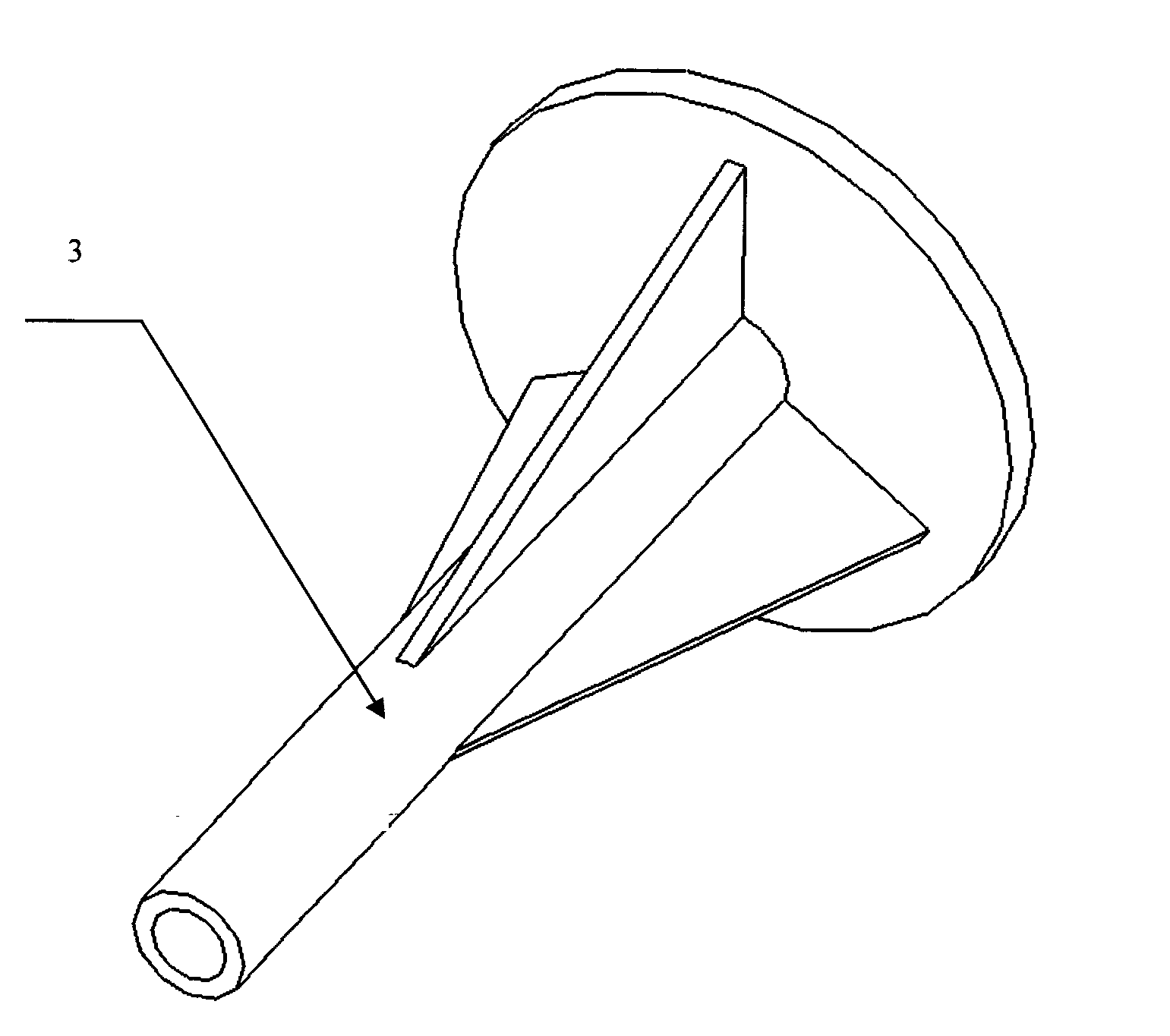

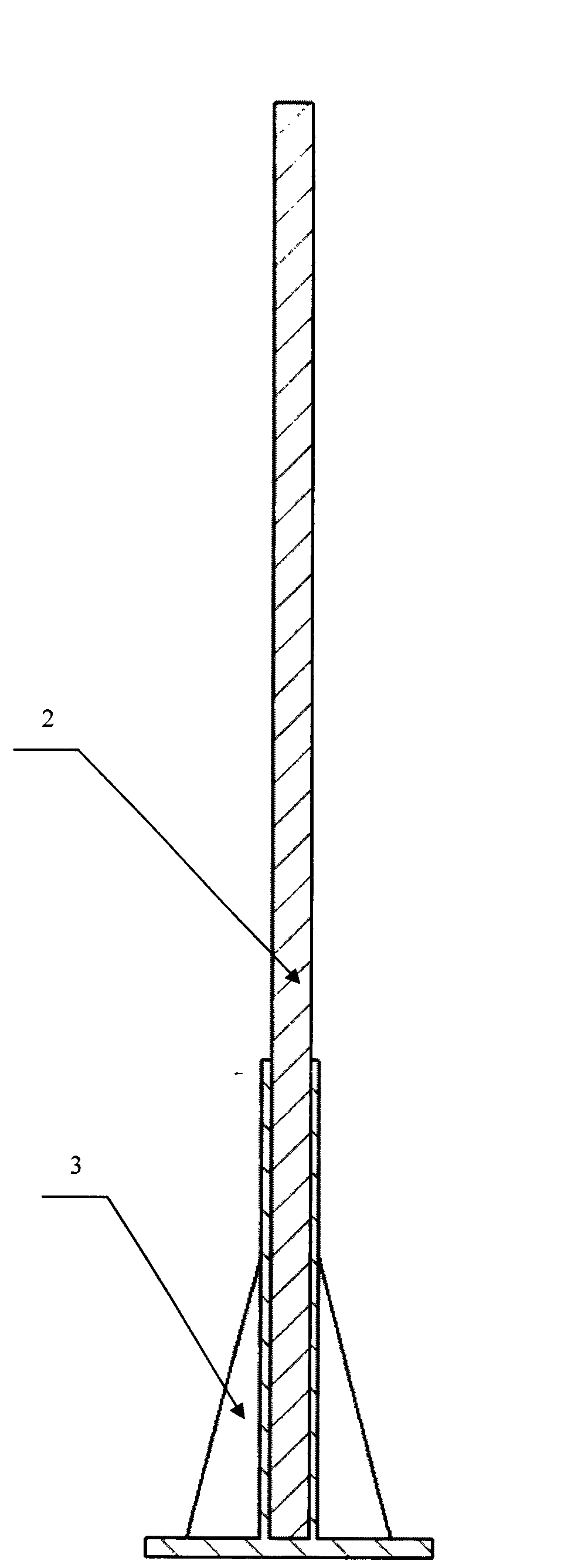

[0022] The base 3 and the benchmark post 2 of the present invention cooperate with the Morse taper hole to realize the precise coaxial positioning of the base 3 and the benchmark post 2, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com