High-current plug connector

A plug-in connector and high-current technology, which is applied in the direction of connection, parts and circuits of the connection device, can solve the problem of large installation space, and achieve the goal of reducing installation space, optimizing spring characteristics, and reliable and large-area contact Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

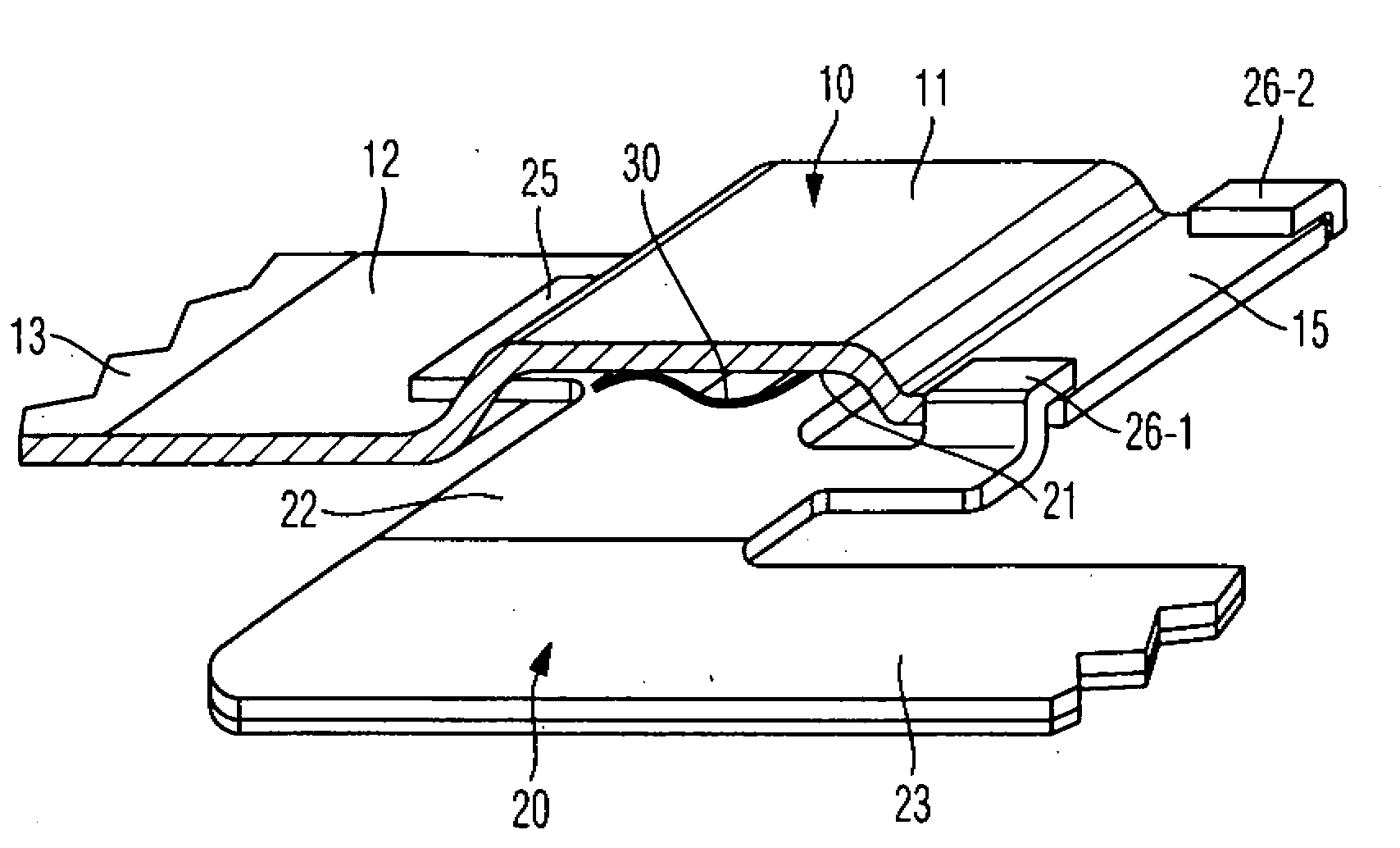

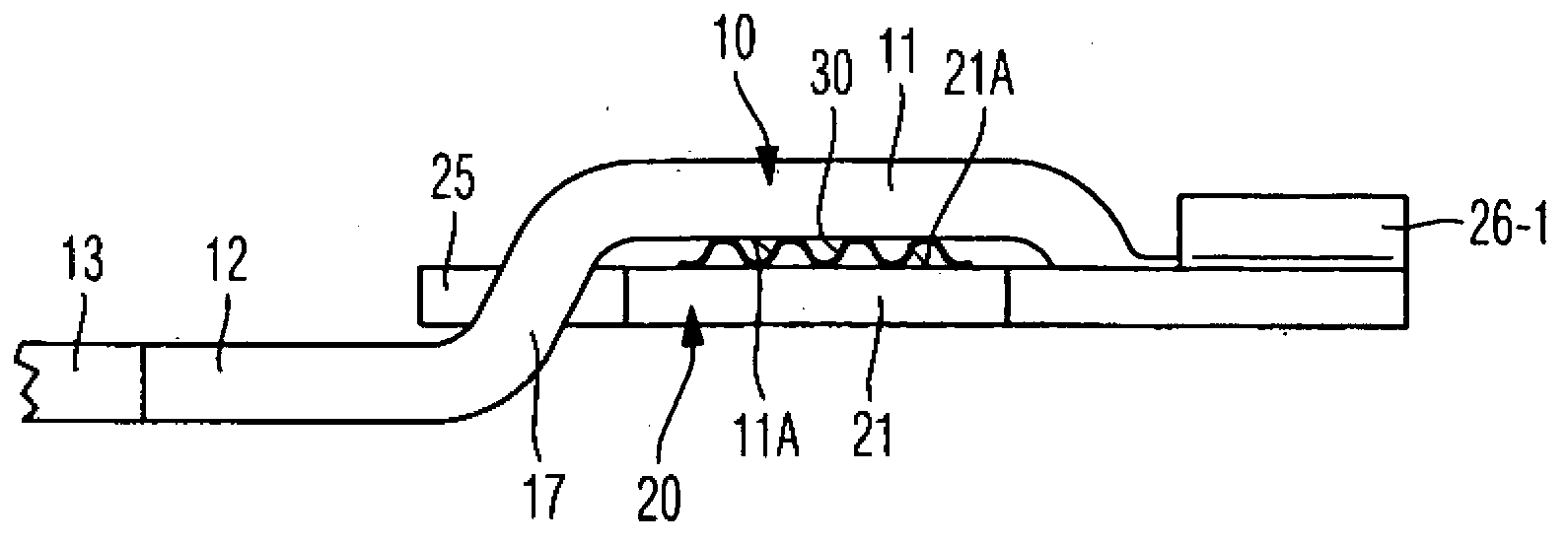

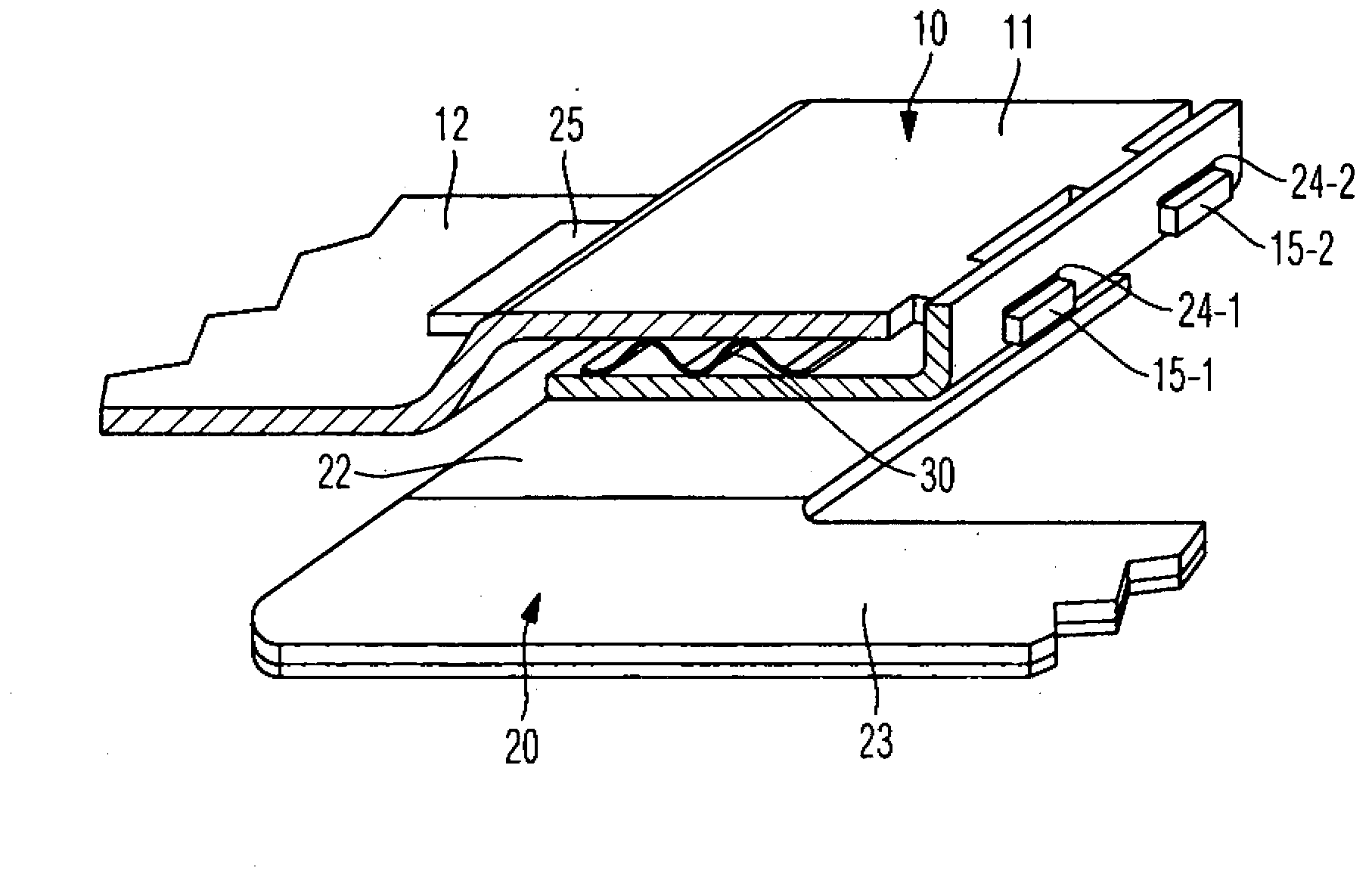

[0027] figure 1 A schematic perspective view of a high-current plug connector according to the invention is shown. The high current plug connector is suitable for currents greater than 100 amperes, even greater than 200 amperes. Currents of this magnitude occur, for example, in energy accumulators for motor vehicle drives. The high-current plug connector comprises a first connecting element 10 and a corresponding second connecting element 20 . The first connection element 10 has a first contact section 11 and a first connection section 12 . An electrical conductor 13 is connected to the first connection section 12 , which is not shown in detail in the drawing and is designed, for example, as a flat cable or as a membrane. Correspondingly, the second connection element 20 has a second contact section 21 and a second connection section 22 . The second connection section 22 is connected, for example at its end face, to an electrical conductor 23 configured as a diaphragm.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com