Automobile lock reinforcing plate part die

A technology for reinforcing plates and car locks, applied in forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of increased maintenance and replacement costs, low production efficiency, long manufacturing cycle, etc., to achieve low production costs, convenient maintenance, The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

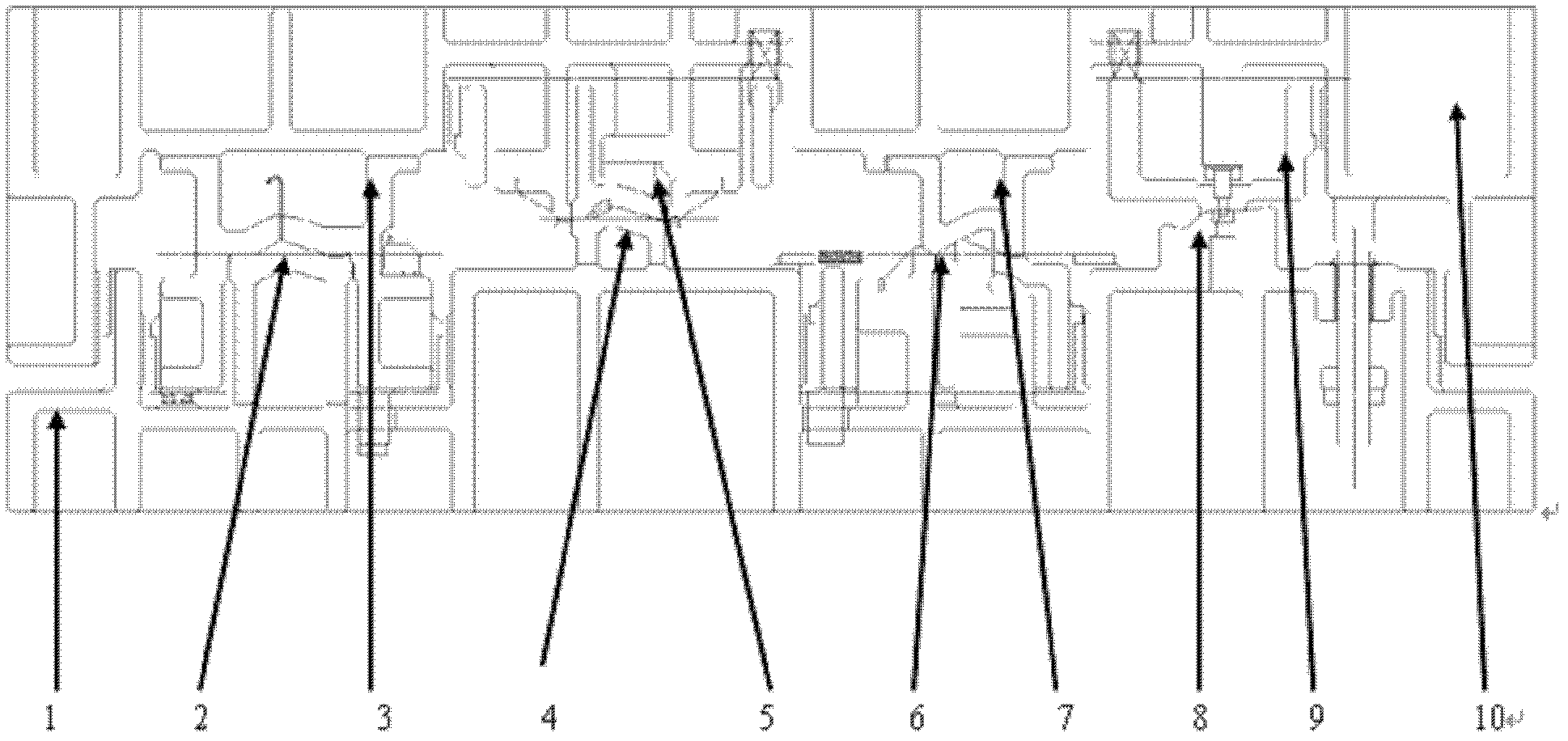

[0014] Such as figure 1 Shown, a kind of automotive lock reinforcing plate part mold, comprises lower mold and upper mold, and lower mold is provided with trimming punch punch 2, first flanging shaping punch 4, second flanging shaping punch 6 and side punch Punch 8, the lower mold also includes a lower mold base 1, a lower mold core and a ejector, the lower mold core and the ejector are arranged on the lower mold base, the trimming and punching punch 2, the first flanging shaping punch 4, the second Two flanging shaping punches 6 and side punching punches 8 are successively arranged on the lower mold core; the upper die is provided with a trimming punching die 3 corresponding to the lower die, a first flanging shaping die 5, a second turning die Edge shaping die 7 and side punching die 9, patrix also comprises patrix 10, patrix core, patrix insert, patrix presser and upper ejector pin, patrix is arranged below patrix, repairs The side punching die 3, the first flanging shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com