Bidirectional pressure regulating pre-tensioner for electric spindle angular contact ball bearing

A technology for angular contact ball bearings and electric spindles, applied in the direction of shafts and bearings, bearing assembly, bearing components, etc., can solve the problems of high manufacturing and maintenance costs, complex structure, limited scope of application, etc., to improve progress and service life, The effect of constant axial preload and guaranteed rotation accuracy and rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

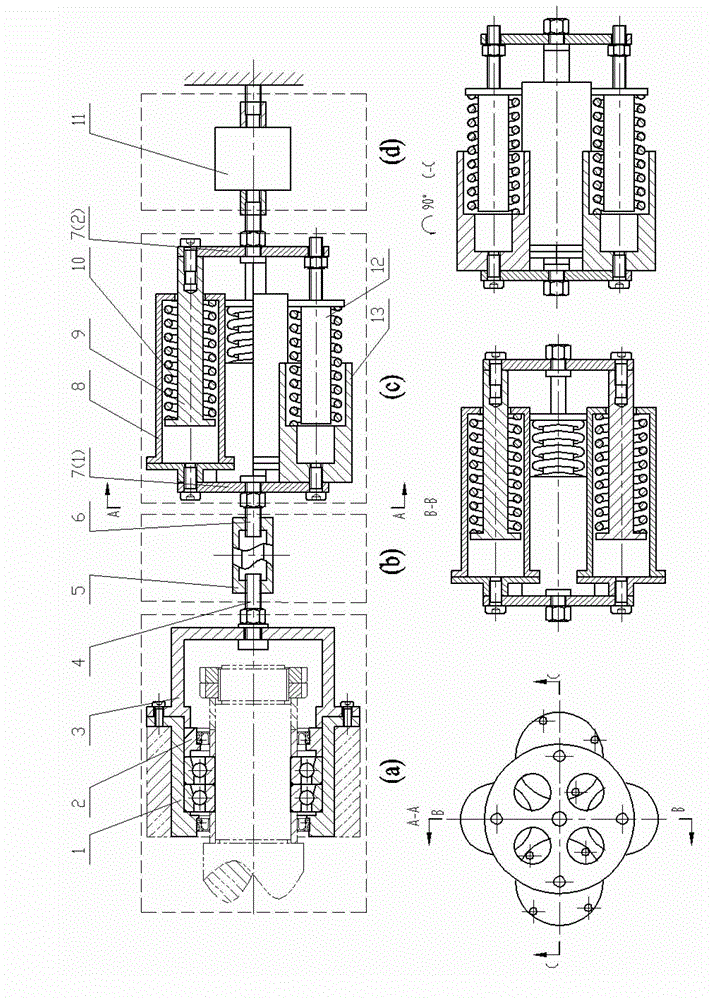

[0022] The following description will be made in conjunction with the accompanying drawings, but the present invention is not limited to the following examples.

[0023] The device consists of four parts, including: pressure ring a, loading sleeve (b), elastic component c, bidirectional force sensor d;

[0024] Pressure ring a and b loading sleeve are connected through a set of M12 left-handed bolts, washers and nuts; loading sleeve (b) and c elastic unit are connected through a set of M12 right-handed bolts, washers and nuts; c elastic unit and The two-way force sensor d is connected by a set of M12 right-handed bolts and nuts;

[0025] The pressure ring a consists of a bearing outer ring support sleeve 1, a bearing sealing ring 2, and a thrust ring 3; the bearing outer ring support sleeve 1 and the bearing seat can slide axially, and the bearing outer ring support sleeve 1 is in angular contact with the electric spindle. Outside the ball bearing, one end of the bearing oute...

Embodiment 2

[0036] Description will be made below in conjunction with the accompanying drawings.

[0037] Axial compressive preload is required for angular contact ball bearing sets. according to figure 1 In the connection method shown, rotating the hexagonal sleeve 5 draws the pressure ring and the elastic unit closer to generate axial pressure preload, and check the pressure value displayed by the sensor 11 to accurately preload the bearing.

[0038]At this time, the bearing sealing ring 2 of the bearing in the pressure ring a withstands the outer ring of the bearing and drives the outer ring of the bearing to move away from the shaft end, and axial slippage occurs between the outer ring support sleeve 1 and the bearing support seat. The bearing seal ring 2, the thrust ring 3 and the outer ring support sleeve 1 synchronously generate an axial leftward displacement. In the elastic unit, the pull rod 9 is close to the extension spring sleeve 8 and does not bear axial force, and the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com